Nissan Sentra Service Manual: Brake pedal

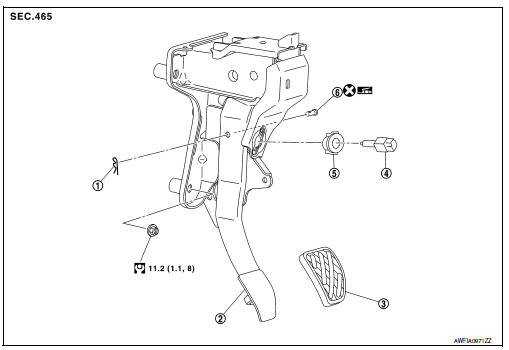

Exploded View

WITHOUT BRAKE PEDAL POSITION SWITCH

- Snap pin

- Brake pedal assembly

- Brake pedal pad

- Stop lamp switch

- Clip

- Clevis pin

Apply multi-purpose grease.

Apply multi-purpose grease.

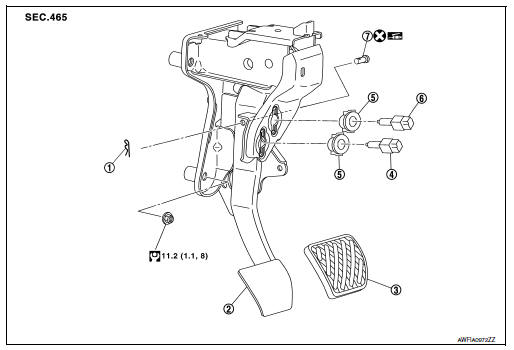

WITH BRAKE PEDAL POSITION SWITCH

- Snap pin

- Brake pedal assembly

- Brake pedal pad

- Brake pedal position switch

- Clip

- Stop lamp switch

Apply multi-purpose grease.

Apply multi-purpose grease.

Removal and Installation

REMOVAL

- Remove instrument lower panel LH. Refer to IP-21, "Removal and Installation".

- Remove steering column lower cover. Refer to IP-16, "Removal and Installation".

- Disconnect the harness connectors from the brake pedal position switch (if equipped) and the stop lamp switch.

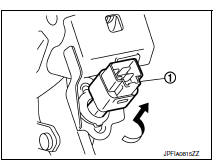

- Rotate the stop lamp switch and the brake pedal position switch (if equipped) (1) counter clockwise to remove.

- Disconnect the accelerator pedal harness connector and harness clip.

- Remove snap pin and clevis pin from clevis on brake booster.

- Remove the brake pedal assembly.

CAUTION:

Secure the brake booster and brake master cylinder to avoid damage to components.

- Remove accelerator pedal from brake pedal assembly. Refer to ACC-3, "Removal and Installation".

INSPECTION AFTER REMOVAL

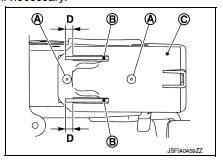

Check for the following items and replace the brake pedal assembly, if necessary.

- Check the brake pedal upper rivet (A) for damage or wear.

- Check the brake pedal for bend, damage, and cracks on the welded parts.

- Check the lapping length (D) of sub-bracket (B) and slide plate (C).

Lapping length (D) : 6.5 mm (0.256 in) or more

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse the clevis pin.

- Install the clevis pin in the proper direction. Refer to BR-22, "Exploded View".

- Apply multi-purpose grease to the clevis pin and the mating faces, if necessary.

ADJUSTMENT AFTER INSTALLATION

- Adjust each item of brake pedal after installing the brake pedal assembly to the vehicle. Refer to BR-15, "Adjustment".

- Perform the release position learning of the accelerator pedal. Refer to EC-138, "Work Procedure".

Brake piping

Brake piping

FRONT

FRONT : Exploded View

Brake tube

ABS actuator and electric unit (control

unit)

Connector

Connector bracket

Master cylinder assembly

Brake booster

Lock plate

Brake hose

...

Other materials:

Hazard warning flasher switch

Push the switch on to warn other drivers when

you must stop or park under emergency conditions.

All turn signal lights flash.

WARNING

If stopping for an emergency, be sure to

move the vehicle well off the road.

Do not use the hazard warning flashers

while moving on th ...

DTC/circuit diagnosis

U1000 CAN COMM CIRCUIT

Description

Refer to lan-7, "can communication system : system description".

Dtc logic

Dtc detection logic

Note:

U1000 can be set if a module harness was disconnected and reconnected,

perhaps during a repair. Confirm

that there are actual CAN diagnostic symp ...

Front fog lamp circuit

Description

The ipdm e/r (intelligent power distribution module engine room) controls the

front fog lamp relay based on

inputs from the bcm over the can communication lines. When the front fog lamp

relay is energized, power

flows from the front fog lamp relay in the ipdm e/r to the front fog ...