Nissan Sentra Service Manual: Brake piping

FRONT

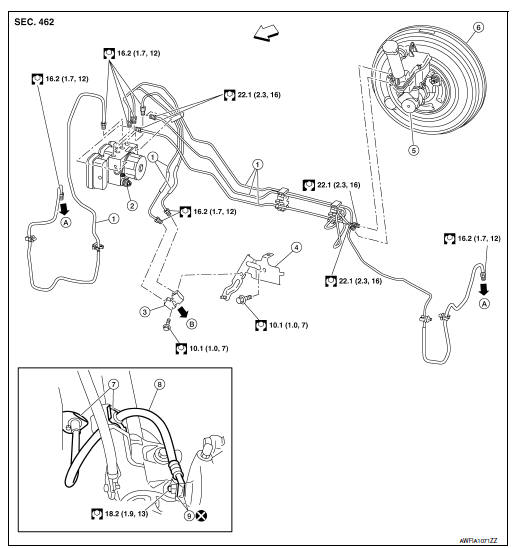

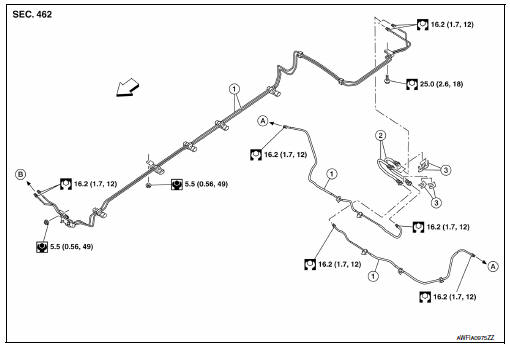

FRONT : Exploded View

- Brake tube

- ABS actuator and electric unit (control unit)

- Connector

- Connector bracket

- Master cylinder assembly

- Brake booster

- Lock plate

- Brake hose

- Copper sealing washer

- To front brake hose

- To rear brake pipe

Front

Front

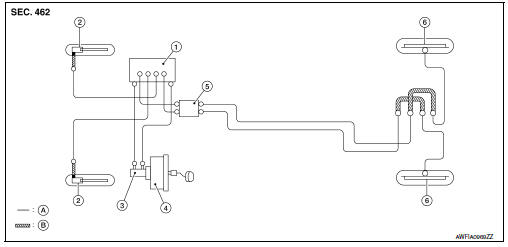

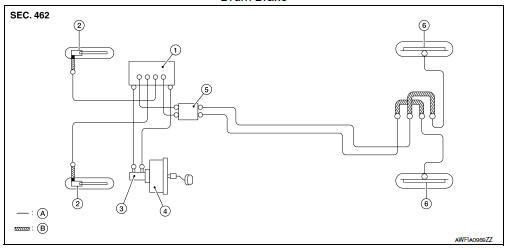

FRONT : Hydraulic Piping

Drum Brake

- ABS actuator and electric unit (control unit)

- Front disc brake

- Master cylinder assembly

- Brake booster

- Connector

- Rear drum brake

- Brake tube

- Brake hose

Flare nut

Flare nut

Union bolt

Union bolt

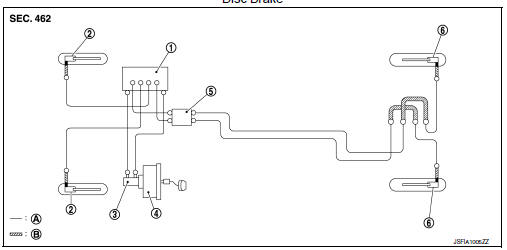

Disc Brake

- ABS actuator and electric unit (control unit)

- Front disc brake

- Master cylinder assembly

- Brake booster

- Connector

- Rear disc brake

- Brake tube

- Brake hose

Flare nut

Flare nut

Union bolt

Union bolt

CAUTION:

- All hoses and piping (tubes) must be free from excessive bending, twisting and pulling.

- Make sure there is no interference with other parts when turning steering wheel both clockwise and counterclockwise.

- The brake piping is an important safety part. If a brake fluid leak is detected, always disassemble the parts. Replace applicable part with a new one, if necessary.

- Do not spill or splash brake fluid on painted surfaces. Brake fluid may damage paint. If brake fluid is splashed on painted areas, wash it away with water immediately.

- Do not bend or twist brake hose sharply, or strongly pull it.

- When removing components, cover connections so that no dirt, dust, or other foreign matter gets in.

- Do not reuse drained brake fluid.

- After installation of the ABS actuator and electric unit (control unit), refill brake system with new brake fluid. Then bleed the air from the system. Refer to BR-17, "Bleeding Brake System".

FRONT : Removal and Installation

NOTE:

When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

REMOVAL

- Remove wheels and tires using power tool. Refer to WT-47, "Removal and Installation".

- Drain brake fluid. Refer to BR-17, "Drain and Refill".

- Loosen the flare nut with suitable tool and separate the brake pipe from the hose.

CAUTION:

- Do not scratch the flare nut and the brake pipe.

- All brake hoses and pipes must be free from excessive bending, twisting and pulling.

- Remove the union bolt and the brake hose from the brake caliper assembly. Remove and discard the copper sealing washers.

CAUTION:

Do not reuse copper sealing washers.

- Remove the lock plate and remove the brake hose.

INSTALLATION

CAUTION:

Do not allow foreign matter (e.g. dust) and oils other than brake fluid to enter the reservoir tank.

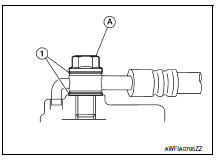

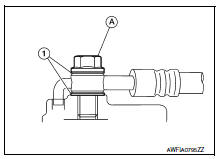

- Assemble the union bolt (A) and the copper sealing washers (1)

to the brake hose and install it as an assembly to the caliper.

Align the brake hose L-pin by aligning it with the brake caliper assembly hole, and tighten the union bolt (1) to the specified torque.

CAUTION:

Do not reuse copper sealing washers.

- Install the brake pipe to the brake hose, temporarily tighten the flare nut by hand until it does not rotate further, and secure the brake hose to the bracket with the lock plate.

CAUTION:

Check that the brake hoses and pipes are not bent or twisted.

- Tighten the flare nut to the specified torque with a flare nut torque wrench.

CAUTION:

Do not scratch the flare nut and the brake tube.

- Refill with new brake fluid and perform the air bleeding. Refer to BR-17, "Bleeding Brake System".

CAUTION:

Do not reuse drained brake fluid.

- Install the wheels and tires. Refer to WT-47, "Removal and Installation".

Rear

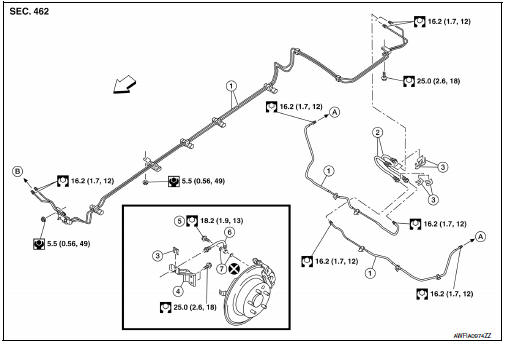

REAR : Exploded View

Drum Brake

- Brake tube

- Brake hose

- Lock plate

- To drum brake

- To brake pipe connector

Front

Front

Disc Brake

- Brake tube

- Brake hose

- Lock plate

- Brake hose bracket

- Union bolt

- Rear brake hose

- Copper sealing washer

- To disc brake

- To brake pipe connector

Front

Front

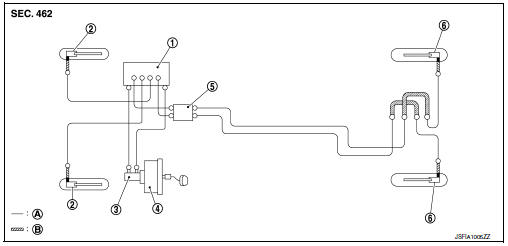

REAR : Hydraulic Piping

Drum Brake

- ABS actuator and electric unit (control unit)

- Front disc brake

- Master cylinder assembly

- Brake booster

- Connector

- Rear drum brake

- Brake tube

- Brake hose

Flare nut

Flare nut

Union bolt

Union bolt

Disc Brake

- ABS actuator and electric unit (control unit)

- Front disc brake

- Master cylinder assembly

- Brake booster

- Connector

- Rear disc brake

- Brake tube

- Brake hose

Flare nut

Flare nut

Union bolt

Union bolt

CAUTION:

- All hoses and piping (tubes) must be free from excessive bending, twisting and pulling.

- Make sure there is no interference with other parts.

- The brake piping is an important safety part. If a brake fluid leak is detected, always disassemble the parts. Replace applicable part with a new one, if necessary.

- Do not spill or splash brake fluid on painted surfaces. Brake fluid may damage paint. If brake fluid is splashed on painted areas, wash it away with water immediately.

- Do not bend or twist brake hose sharply, or strongly pull it.

- When removing components, cover connections so that no dirt, dust, or other foreign matter gets in.

- Do not reuse drained brake fluid.

- After installation of the ABS actuator and electric unit (control unit), refill brake system with new brake fluid. Then bleed the air from the system. Refer to BR-17, "Bleeding Brake System".

REAR : Removal and Installation

DRUM BRAKES

NOTE:

When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

Removal

CAUTION:

Do not spill or splash brake fluid on painted surfaces. Brake fluid may damage paint. If brake fluid is splashed on painted areas, wash it away with water immediately.

- Remove wheels and tires using power tool. Refer to WT-47, "Removal and Installation".

- Drain brake fluid. Refer to BR-17, "Drain and Refill".

- Loosen the flare nut with suitable tool and separate the brake pipe from the brake hose.

CAUTION:

- Do not scratch the flare nut and the brake pipe.

- All brake hoses and pipes must be free from excessive bending, twisting and pulling.

- Remove the lock plate and remove the brake hose from the vehicle.

- Loosen the flare nut with a flare nut wrench and separate the brake pipe from the wheel cylinder, and remove the brake pipe.

Installation

- Connect the brake pipe to the wheel cylinder, temporarily tighten the flare nut by hand until it does not rotate further.

- Connect the brake hose to the brake pipe, temporarily tighten the flare nut by hand until it does not rotate further, and secure the brake hose to the bracket with the lock plate.

CAUTION:

Check that the brake hoses and pipes are not bent or twisted.

- Tighten the flare nut to the specified torque using suitable tool.

CAUTION:

Do not scratch the flare nut and the brake tube.

- Refill with new brake fluid and perform the air bleeding. Refer to BR-17, "Bleeding Brake System".

CAUTION:

Do not reuse drained brake fluid.

- Install the wheels and tires. Refer to WT-47, "Removal and Installation".

Disc brakes

NOTE:

When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

Removal

- Remove the wheels and tires using power tool. Refer to WT-47, "Removal and Installation".

- Drain brake fluid. Refer to BR-17, "Drain and Refill".

- Loosen the flare nut with suitable tool and separate the brake tube from the hose.

CAUTION:

- Do not scratch the flare nut and the brake pipe.

- All brake hoses and pipes must be free from excessive bending, twisting and pulling.

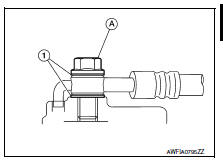

- Remove the union bolt (A) and the brake hose from the brake caliper. Remove and discard the copper sealing washers (1).

CAUTION:

Do not reuse copper sealing washers.

- Remove the lock plate and remove the brake hose.

Installation

CAUTION:

Do not allow foreign matter (e.g. dust) and oils other than brake fluid to enter the reservoir tank.

Assemble the union bolt (A) and the copper sealing washers (1) to the brake hose and install it as an assembly to the brake caliper.

Align the brake hose L-pin by aligning it with the brake caliper hole, and tighten the union bolt (A) to the specified torque.

CAUTION:

Do not reuse copper sealing washers.

- Install the brake pipe to the brake hose, temporarily tighten the flare nut by hand until it does not rotate further, and attach the brake hose to the bracket with the lock plate.

CAUTION:

Check that the brake hoses and pipes are not bent or twisted.

- Tighten the flare nut to the specified torque using suitable tool.

CAUTION:

Do not scratch the flare nut and the brake pipe.

- Refill with new brake fluid and perform the air bleeding. Refer to BR-17, "Bleeding Brake System".

CAUTION:

Do not reuse drained brake fluid.

- Install the wheels and tires. Refer to WT-47, "Removal and Installation".

Brake pedal

Brake pedal

Exploded View

WITHOUT BRAKE PEDAL POSITION SWITCH

Snap pin

Brake pedal assembly

Brake pedal pad

Stop lamp switch

Clip

Clevis pin

Apply multi-purpose grease.

WITH BRAKE PEDAL POSI ...

Brake master cylinder

Brake master cylinder

Exploded View

Reservoir cap

Oil strainer

Reservoir tank

Cylinder body

Pin

O-ring

Grommet

Apply brake fluid

PBC (Poly Butyl Cuprysil)

grease or

silicone-based grease

Remo ...

Other materials:

Basic inspection

Diagnosis and repair workflow

Work flow

OVERALL SEQUENCE

DETAILED FLOW

1.GET INFORMATION FOR SYMPTOM

Get detailed information from the customer about the symptom (the condition

and the environment when the

incident/malfunction occurred).

>> GO TO 2

2.CONFIRM THE SYMPTOM

Try to ...

Vanity mirror lamp

Removal and installation

Caution:

Do not attempt to separate the vanity mirror lamp from the sun visor or

damage to the components

may occur.

Note:

The vanity mirror lamp is replaced as part of the sun visor. Refer to

int-40, "removal and installation".

Bulb or lens replacement

...

Exhaust valve timing control

EXHAUST VALVE TIMING CONTROL : System

Description

SYSTEM DIAGRAM

INPUT/OUTPUT SIGNAL CHART

Sensor

Input signal to ECM

ECM function

Actuator

Crankshaft position sensor (POS)

Engine speed and piston position

Exhaust valve

timing control

Exhaust valve timing ...