Nissan Sentra Service Manual: Rear disc brake

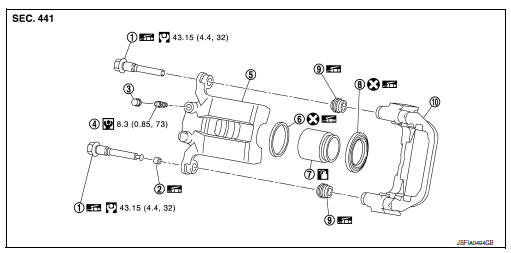

Exploded View

- Sliding pin bolt

- Bushing

- Cap

- Bleeder valve

- Cylinder body

- Piston seal

- Piston

- Piston boot

- Sliding pin boot

- Torque member

Apply rubber grease

Apply rubber grease

Apply brake fluid

Apply brake fluid

Disassembly and Assembly

DISASSEMBLY

- Place a wooden block as shown, and blow air from union bolt hole to remove piston and piston boot.

WARNING:

Do not get fingers caught between piston and cylinder body.

- Remove piston seal from cylinder body using suitable tool.

CAUTION:

Do not damage cylinder inner wall.

- Remove bleeder valve and cap.

ASSEMBLY

- Install bleeder valve and cap.

- Apply rubber grease to piston seal (1), and install to cylinder body.

CAUTION:

Do not reuse piston seal.

- Apply rubber grease to piston boot (1). Cover the piston (2) end with piston boot, and install cylinder side lip on piston boot securely into a groove on cylinder body.

CAUTION:

Do not reuse piston boot.

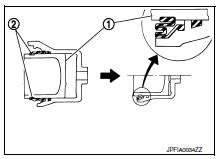

- Apply new brake fluid to piston (1). Push piston into cylinder body by hand and push piston boot (2) piston-side lip into the piston groove.

CAUTION:

Press the piston evenly and vary the pressing point to prevent cylinder inner wall from being rubbed.

Rear drum brake

Rear drum brake

Exploded View

Cap

Bleeder valve

Piston

Spring

Boot

Piston cup

Wheel cylinder

Apply rubber grease

Apply PBC (Poly Butyl Cuprysil)

grease or silicone-based grease

Apply ...

Service data and specifications (SDS)

Service data and specifications (SDS)

General Specifications

Brake Pedal

Check Valve

Brake Booster

Front Disc Brake

Rear Drum Brake

Rear Disc Brake

...

Other materials:

Chassis and body maintenance

In-cabin microfilter

In-cabin microfilter : removal and installation

REMOVAL

Remove the in-cabin microfilter cover.

CAUTION:

Before removing the in-cabin microfilter cover, let the vehicle rest

for at least 30 minutes.

Release the filter cover tab (A), then pull the bottom of the in- ...

Ipdm-e branch line circuit

Diagnosis procedure

1.Check connector

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the IPDM E/R for damage, bend and

loose connection (unit side

and connector side).

Is the inspection result normal?

Yes ...

C1164, C1165, C1166, C1167 CV/SV System

DTC Logic

Dtc detection logic

DTC

Display Item

Malfunction detected condition

Possible causes

C1164

CV 1

When a malfunction is detected in cut valve 1.

Harness or connector

ABS actuator and electric unit

(control unit)

Fusible link

Battery ...