Nissan Sentra Service Manual: Power window motor

DRIVER SIDE

DRIVER SIDE : Description

Door glass moves up/down by receiving the signal from main power window and door lock/unlock switch

DRIVER SIDE : Component Function Check

1. Check front power window motor lh circuit

Check front power window motor lh operation with the main power window and door lock/unlock switch.

Is the inspection result normal? Yes >> front power window motor lh is ok.

No >> refer to pwc-43, "driver side : diagnosis procedure".

DRIVER SIDE : Diagnosis Procedure

Regarding Wiring Diagram information, refer to PWC-18, "Wiring Diagram".

Front power window motor lh circuit check

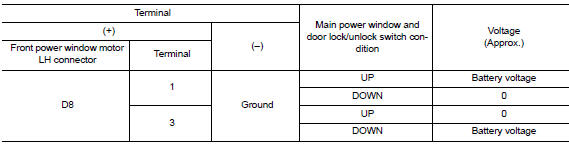

1. Check main power window and door lock/unlock switch output signal

- Turn ignition switch off.

- Disconnect front power window motor lh.

- Turn ignition switch ON.

- Check voltage between front power window motor LH connector D8 and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

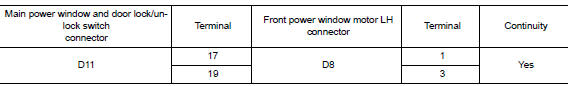

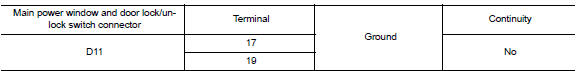

2. Check harness continuity

- Turn ignition switch off.

- Disconnect main power window and door lock/unlock switch.

- Check continuity between main power window and door lock/unlock switch connector d11 and front power window motor lh connector d8.

- Check continuity between main power window and door lock/unlock switch connector D11 and ground.

Is the inspection result normal? Yes >> replace main power window and door lock/unlock switch. Refer to pwc-70, "removal and installation".

After that, refer to pwc-29, "work procedure".

No >> repair or replace harness.

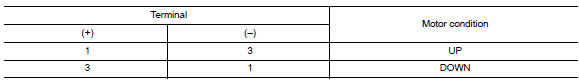

3. Check front power window motor lh

Check front power window motor lh.

Refer to pwc-44, "driver side : component inspection".

Is the inspection result normal? Yes >> check intermittent incident. Refer to gi-39, "intermittent incident".

No >> replace front power window motor lh. Refer to gw-16, "removal and installation". After that, refer to pwc-29, "work procedure".

DRIVER SIDE : Component Inspection

Component inspection

1.Check front power window motor lh

Check motor operation by connecting the battery voltage directly to power window motor d8.

Is the inspection result normal? Yes >> front power window motor lh is ok.

No >> replace front power window motor lh. Refer to gw-16, "removal and installation". After that, refer to pwc-29, "work procedure".

DRIVER SIDE : Special Repair Requirement

1. Perform initialization procedure

Perform initialization procedure.

Refer to PWC-29, "Work Procedure".

Is the inspection result normal? YES >> GO TO 2.

NO >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

2. Check anti-pinch operation

Check anti-pinch operation.

Refer to pwc-30, "work procedure".

Is the inspection result normal? Yes >> inspection end.

No >> refer to pwc-43, "driver side : component function check".

PASSENGER SIDE

PASSENGER SIDE : Description

Door glass moves UP/DOWN by receiving the signal from main power window and door lock/unlock switch or power window and door lock/unlock switch RH.

PASSENGER SIDE : Component Function Check

1. Check front power window motor rh circuit

Check front power window motor RH operation with main power window and door lock/unlock switch or power window and door lock/unlock switch.

Is the inspection result normal? YES >> Front power window motor RH is OK.

NO >> Refer to PWC-45, "PASSENGER SIDE : Diagnosis Procedure".

PASSENGER SIDE : Diagnosis Procedure

Regarding wiring diagram information, refer to pwc-18, "wiring diagram".

Front power window motor rh circuit check

1. Check power window and door lock/unlock switch rh output signal

- Turn ignition switch OFF

- Disconnect front power window motor rh.

- Turn ignition switch on.

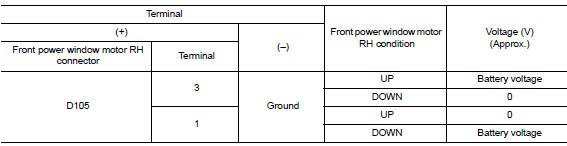

- Check voltage between front power window motor RH connector D105 and ground.

Is the inspection result normal? Yes >> go to 3.

No >> go to 2.

2. Check harness continuity

- Turn ignition switch off.

- Disconnect power window and door lock/unlock switch RH.

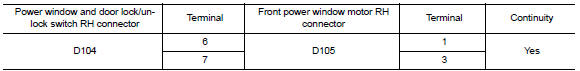

- Check continuity between power window and door lock/unlock switch RH connector D104 and front power window motor RH connector D105.

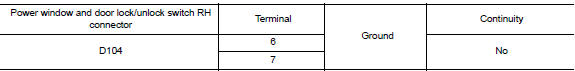

- Check continuity between power window and door lock/unlock switch connector D104 and ground.

Is the inspection result normal? Yes >> replace power window and door lock/unlock switch rh. Refer to pwc-71, "removal and installation".

No >> repair or replace the harness or connectors.

3. Check front power window motor rh

Check front power window motor rh.

Refer to pwc-46, "passenger side : component inspection".

Is the inspection result normal? Yes >> check intermittent incident. Refer to gi-39, "intermittent incident".

No >> replace front power window motor rh. Refer to gw-16, "removal and installation".

PASSENGER SIDE : Component Inspection

Component inspection

1. Check front power window motor rh

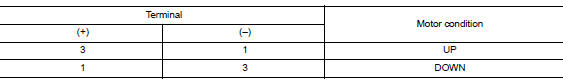

Check motor operation by connecting the battery voltage directly to front power window motor rh d105.

Is the inspection result normal? Yes >> power window motor is ok.

No >> replace front power window motor rh. Refer to gw-16, "removal and installation".

REAR LH

REAR LH : Description

Door glass moves up/down by receiving the signal from main power window and door lock/unlock switch or rear power window switch lh.

REAR LH : Component Function Check

1. Check rear power window motor lh circuit

Check rear power window motor lh operation with main power window and door lock/unlock switch or rear power window switch lh.

Is the inspection result normal? Yes >> rear power window motor lh is ok.

No >> refer to pwc-46, "rear lh : diagnosis procedure"

REAR LH : Diagnosis Procedure

Regarding wiring diagram information, refer to pwc-18, "wiring diagram".

Rear Power Window Motor LH Circuit Check

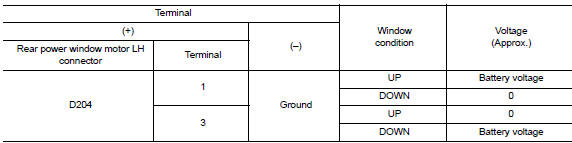

1. Check rear power window switch lh output signal

- Turn ignition switch OFF

- Disconnect rear power window motor lh.

- Turn ignition switch on.

- Check voltage between rear power window motor LH connector D204 and ground.

Is the inspection result normal? Yes >> go to 3.

No >> go to 2.

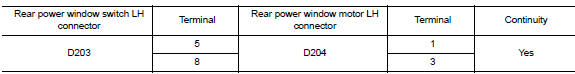

2. Check harness continuity

- Turn ignition switch off

- Disconnect rear power window switch lh.

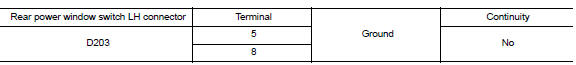

- Check continuity between rear power window switch lh connector d203 and rear power window motor lh connector d204.

- Check continuity between rear power window switch lh connector d203 and ground.

The inspection result normal? Yes >> check rear power window switch lh. Refer to pwc-47, "rear lh : component inspection".

No >> repair or replace the harness or connectors.

Is the inspection result normal? Yes >> check rear power window switch lh. Refer to pwc-47, "rear lh : component inspection".

No >> repair or replace the harness or connectors.

3. Check rear power window motor lh

Check rear power window motor lh.

Refer to pwc-47, "rear lh : component inspection".

Is the inspection result normal? Yes >> check intermittent incident. Refer to gi-39, "intermittent incident".

No >> replace rear power window motor lh. Refer to gw-21, "removal and installation".

REAR LH : Component Inspection

Component inspection

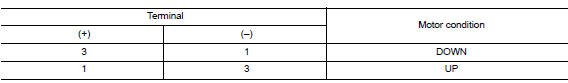

1. Check rear power window motor lh

Check motor operation by connecting the battery voltage directly to rear power window motor LH D204.

Is the inspection result normal? YES >> Rear power window motor LH is OK.

NO >> Replace rear power window motor LH. Refer to GW-21, "Removal and Installation".

REAR RH

REAR RH : Description

Door glass moves UP/DOWN by receiving the signal from main power window and door lock/unlock switch or rear power window switch RH.

REAR RH : Component Function Check

1. Check power window motor circuit

Check rear power window motor rh operation with operating power window main switch or rear power window switch rh.

Is the inspection result normal? Yes >> power window motor is ok.

No >> refer to pwc-48, "rear rh : diagnosis procedure".

REAR RH : Diagnosis Procedure

Regarding Wiring Diagram information, refer to PWC-18, "Wiring Diagram".

Rear power window motor rh circuit check

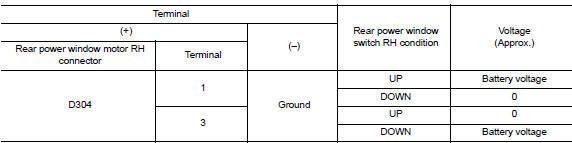

1. Check rear power window switch rh output signal

- Turn ignition switch OFF.

- Disconnect rear power window motor rh.

- Turn ignition switch ON.

- Check voltage between rear power window motor rh connector d304 and ground.

Is the inspection result normal? Yes >> go to 3.

No >> go to 2.

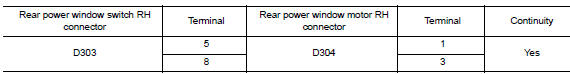

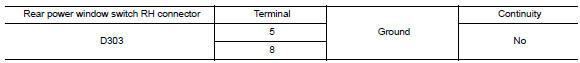

2. Check harness continuity

- Turn ignition switch OFF.

- Disconnect rear power window switch rh.

- Check continuity between rear power window switch RH connector D303 and rear power window motor RH connector D304.

- Check continuity between rear power window switch rh connector d303 and ground

Is the inspection result normal? Yes >> check rear power window switch rh. Refer to pwc-49, "rear rh : component inspection".

No >> repair or replace harness or connectors.

3. Check rear power window motor rh

Check rear power window motor rh.

Refer to pwc-49, "rear rh : component inspection".

Is the inspection result normal? Yes >> check intermittent incident. Refer to gi-39, "intermittent incident".

No >> replace rear power window motor rh. Refer to gw-21, "removal and installation".

REAR RH : Component Inspection

Component inspection

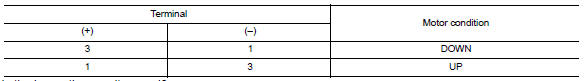

1. Check rear power window motor rh

Check motor operation by connecting the battery voltage directly to rear power window motor rh d304.

Is the inspection result normal? YES >> Power window motor is OK.

NO >> Replace rear power window motor RH. Refer to GW-21, "Removal and Installation".

Power supply and ground circuit

Power supply and ground circuit

BCM (BODY CONTROL SYSTEM) (WITH INTELLIGENT KEY SYSTEM)

BCM (BODY CONTROL SYSTEM) (WITH INTELLIGENT KEY SYSTEM) : Diagnosis Procedure

Regarding Wiring Diagram information, refer to BCS-51, "Wir ...

Encoder

Encoder

Driver side

DRIVER SIDE : Description

Detects condition of the front power window motor lh operation and transmits

to main power window and door

lock/unlock switch as pulse signal.

DRIVER SIDE ...

Other materials:

Preparation

Special Service Tool

The actual shape of the tools may differ from those illustrated here.

Commercial Service Tool

Clip list

Descriptions for clips

Replace any clips which are damaged during removal or installation.

...

Anti-pinch inspection

Description

If any of the following operations are performed, the initialization is

necessary for normal operation of antipinch

function.

Disconnection and connection of battery cable from negative terminal.

When power window main switch replaced.

Electric power supply to power window ma ...

How to use the remote keyless entry function

The remote keyless entry function can operate all

door locks using the remote keyless function of

the Intelligent Key. The remote keyless function

can operate at a distance of 33 ft (10 m) away

from the vehicle. The operating distance depends

upon the conditions around the vehicle.

The remot ...