Nissan Sentra Service Manual: Power supply and ground circuit

Diagnosis procedure

Regarding wiring diagram information, refer to bcs-51, "wiring diagram".

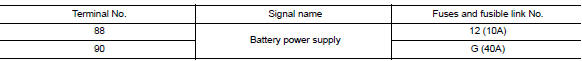

1.Check fuses and fusible link

Check that the following fuses and fusible link are not blown.

Is the fuse blown? YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2.

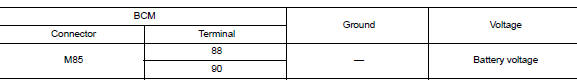

2.Check power supply circuit

- Disconnect bcm connector m85.

- Check voltage between bcm connector m85 and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair harness or connector.

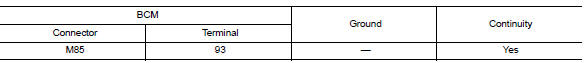

3.Check ground circuit

Check continuity between bcm connector m85 and ground.

Is the inspection result normal? YES >> Inspection End.

NO >> Repair harness or connector.

Combination meter buzzer

Component function check

1.Check function

- Select intelligent key of bcm using consult.

- Select inside buzzer in active test mode.

- Touch Key, Knob or Take Out to check that it works normally.

Is the inspection result normal? Yes >> Combination meter buzzer is OK.

No >> Refer to DLK-91, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK METER BUZZER CIRCUIT

Refer to WCS-28, "Component Function Check".

Is the inspection result normal? Yes >> GO TO 2.

No >> Repair or replace harness.

2.CHECK INTERMITTENT INCIDENT

Refer to GI-39, "Intermittent Incident".

>> Inspection End.

DTC/circuit diagnosis

DTC/circuit diagnosis

U1000 CAN COMM CIRCUIT

Description

Refer to lan-7, "can communication system : system description".

Dtc logic

Dtc detection logic

Note:

U1000 can be set if a module harness was disconn ...

Door lock actuator

Door lock actuator

Driver side

Driver side : component function check

1.CHECK FUNCTION

Select DOOR LOCK of BCM using CONSULT.

Select DOOR LOCK in ACTIVE TEST mode.

Touch ALL LOCK or ALL UNLK to check that it w ...

Other materials:

Checking bulbs

With all doors closed, apply the parking brake

and place the ignition switch in the ON position

without starting the engine. The following lights

will come on:

If equipped, the following lights come on briefly

and then go off:

If any light fails to come on, it may indicate

an open circuit ...

Trunk lid release switch

WARNING

Do not drive with the trunk lid open. This

could allow dangerous exhaust gases

to be drawn into the vehicle. See “Exhaust

gas” in the “Starting and driving”

section of this manual.

Closely supervise children when they

are around cars to prevent ...

Harness connector

Description

Harness connector (tab-locking type)

The tab-locking type connectors help prevent accidental looseness or

disconnection.

The tab-locking type connectors are disconnected by pushing or lifting

the locking tab(s). Refer to the figure

below.

Refer to the next page for desc ...