Nissan Sentra Service Manual: Cooling fan

Component Function Check

1.CHECK COOLING FAN FUNCTION

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Perform “FAN” in “ACTIVE TEST” mode of “ENGINE” using CONSULT

- Check that cooling fan operates at low speed or high speed.

Without CONSULT

Without CONSULT

- Activate IPDM E/R auto active test and check cooling fan motors operation. Refer to PCS-9, "Diagnosis Description" (with intelligent key), or PCS-37, "Diagnosis Description" (without intelligent key).

- Check that cooling fan operates.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-463, "Diagnosis Procedure".

Diagnosis Procedure

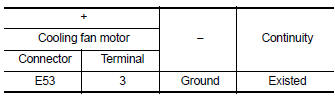

1.CHECK COOLING FAN MOTOR GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect cooling fan motor harness connector

- Check the continuity between cooling fan motor harness connector and ground.

- Also check harness for short to ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace error-detected parts.

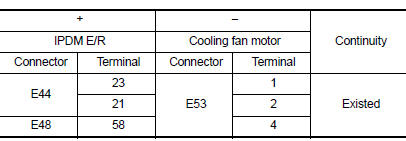

2.CHECK COOLING FAN MOTOR CIRCUIT-1

- Disconnect IPDM E/R harness connector.

- Check the continuity between IPDM E/R harness connector and cooling fan motor harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace error-detected parts.

3.CHECK COOLING FAN MOTOR

Check cooling fan motor. Refer to EC-464, "Component Inspection (Cooling Fan Motor)".

Is the inspection result normal? YES >> GO TO 4.

NO >> Replace cooling fan motor. Refer to CO-17, "Removal and Installation".

4.CHECK INTERMITTENT INCIDENT

Check intermittent incident. Refer to GI-39, "Intermittent Incident".

Is the inspection result normal? YES >> Check IPDM E/R. Refer to PCS-10, "CONSULT Function (IPDM E/R)" (With intelligent key system) or PCS-38, "CONSULT Function (IPDM E/R)" (Without intelligent key system).

NO >> Repair or replace error-detected parts.

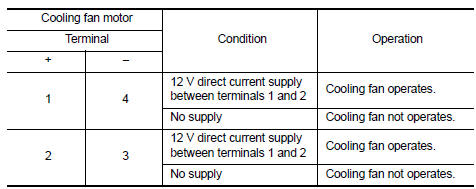

Component Inspection (Cooling Fan Motor)

1.CHECK COOLING FAN MOTOR

Supply cooling fan motor terminals with battery voltage and check operation.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace cooling fan motor. Refer to CO-17, "Removal and Installation".

Electrical load signal

Electrical load signal

Description

The electrical load signal (Headlamp switch signal, rear window defogger

switch signal, etc.) is transferred via

the CAN communication line.

Component Function Check

1.CHECK REAR WIN ...

Refrigerant pressure sensor

Refrigerant pressure sensor

Component Function Check

1.CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

Start engine and warm it up to normal operating temperature.

Turn A/C switch and blower fan switch ON.

Check the ...

Other materials:

Tire pressure

Tire Pressure Monitoring System

(TPMS)

This vehicle is equipped with the Tire

Pressure Monitoring System (TPMS). It

monitors tire pressure of all tires except

the spare. When the low tire pressure

warning light is lit and the CHECK TIRE

PRES warning is displayed in the odometer,

one or more ...

Periodic maintenance

Introduction of periodic maintenance

The following tables show the normal maintenance schedule. Depending upon

weather and atmospheric conditions,

varying road surfaces, individual driving habits and vehicle usage, additional

or more frequent maintenance

may be required.

Periodic maintenan ...

P0520 EOP System

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0520

EOP SENSOR/SWITCH

(Engine oil pressure sensor/

switch circuit)

ECM detects the following status continuously

for 5 seconds ...