Nissan Sentra Service Manual: Diagnosis and repair work flow

Work Flow

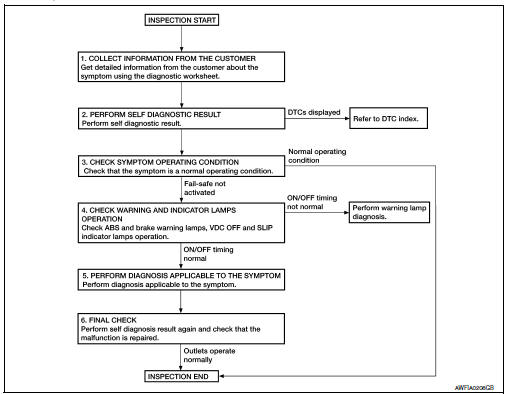

OVERALL SEQUENCE

DETAILED FLOW

1.COLLECT INFORMATION FROM THE CUSTOMER

Get detailed information from the customer about the symptom (the condition and the environment when the incident/malfunction occurred) using the diagnostic worksheet. Refer to BRC-52, "Diagnostic Work Sheet".

>> GO TO 2.

2.PERFORM SELF DIAGNOSTIC RESULT

Perform self diagnostic result. Refer to BRC-31, "CONSULT Function (ABS)".

Are any DTCs displayed? YES >> Refer to BRC-43, "DTC Index".

NO >> GO TO 3.

3.CHECK SYMPTOM OPERATING CONDITION

Check that the symptom is a normal operating condition. Refer to BRC-105, "Description".

Is the symptom a normal operating condition? YES >> Inspection End.

NO >> GO TO 4.

4.CHECK WARNING AND INDICATOR LAMPS OPERATION

Check ABS and brake warning lamps, and VDC OFF and SLIP indicator lamps operation. Refer to MWI-8, "METER SYSTEM : System Description".

Is ON/OFF timing normal? YES >> GO TO 5.

NO >> Perform warning lamp diagnosis. Refer to BRC-94, "Component Function Check" (ABS warning lamp), BRC-95, "Component Function Check" (brake warning lamp), BRC-96, "Component Function Check" (VDC OFF indicator lamp) or BRC-97, "Component Function Check" (SLIP indicator lamp).

5.PERFORM DIAGNOSIS APPLICABLE TO THE SYMPTOM

Perform diagnosis applicable to the symptom. Refer to BRC-98, "Symptom Table".

>> GO TO 6.

6.FINAL CHECK

Perform self diagnostic result again, and check that the malfunction is repaired. After checking, erase the self diagnosis memory. Refer to BRC-31, "CONSULT Function (ABS)".

>> Inspection End

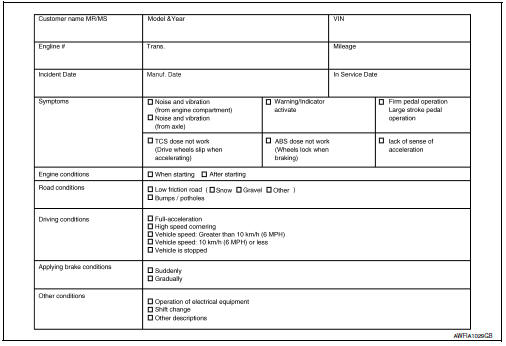

Diagnostic Work Sheet

Additional service when replacing abs actuator and electric unit (control unit)

Description

When replacing the ABS actuator and electric unit (control unit), perform steering angle sensor neutral position adjustment. Refer to BRC-54, "Work Procedure".

Basic inspection

Basic inspection

...

Adjustment of steering angle sensor neutral position

Adjustment of steering angle sensor neutral position

Description

Refer to the table below to determine if adjustment of steering

angle sensor neutral position is required.

×: Required –: Not required

Work Procedure

ADJUSTMENT OF ST ...

Other materials:

Body side trim

Exploded View

Rear body side welt

Front body side welt

Tether clip

Front pillar finisher

Metal clip

Dash clip

Dash side finisher

Harness protector

Front kicking plate inner

Center pillar lower finisher

Rear kicking plate inner

Cap

Center pillar upper finisher

Rear p ...

Component parts

Component parts location

BCM (view with instrument panel removed)

Key switch

(without Intelligent Key)

Push-button ignition switch

(with Intelligent Key)

IPDM E/R

Illumination control switch

Combination switch (lighting and

turn signal switch)

Front door lock LH (key cylin ...

Can communication circuit

Diagnosis procedure

1.Connector inspection

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Disconnect all the unit connectors on CAN communication system.

Check terminals and connectors for damage, bend and loose connection.

Is the inspection resu ...