Nissan Sentra Service Manual: Adjustment of steering angle sensor neutral position

Description

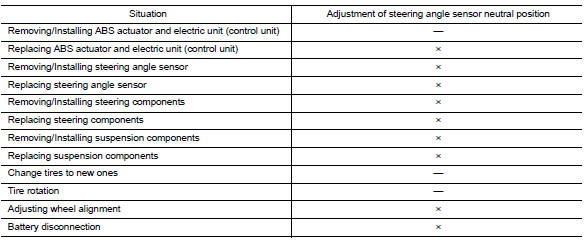

Refer to the table below to determine if adjustment of steering angle sensor neutral position is required.

×: Required –: Not required

Work Procedure

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

CAUTION:

To adjust neutral position of steering angle sensor, make sure to use CONSULT.

(Adjustment cannot be done without CONSULT).

1.ALIGN THE VEHICLE STATUS

Stop vehicle with front wheels in straight-ahead position.

>> GO TO 2.

2.PERFORM THE NEUTRAL POSITION ADJUSTMENT FOR THE STEERING ANGLE SENSOR

-

On the CONSULT screen, touch “WORK SUPPORT” and “ST ANG SEN ADJUSTMENT” in order.

-

Touch “START”.

CAUTION:

Do not touch steering wheel while adjusting steering angle sensor.

-

After approximately 10 seconds, touch “END”.

NOTE:

After approximately 60 seconds, it ends automatically.

-

Turn ignition switch OFF, then turn it ON again.

CAUTION:

Be sure to perform above operation.

>> GO TO 3.

3.CHECK DATA MONITOR

-

Run vehicle with front wheels in straight-ahead position, then stop

-

Select “DATA MONITOR”. Then make sure “STR ANGLE SIG” is within 0±2.5°.

Is the steering angle within the specified range? YES >> GO TO 4.

NO >> Perform the neutral position adjustment for the steering angle sensor again, GO TO 1

4.ERASE THE SELF-DIAGNOSIS MEMORY

Erase the self-diagnosis memory of the ABS actuator and electric unit (control unit) and ECM.

-

ABS actuator and electric unit (control unit): Refer to BRC-31, "CONSULT Function (ABS)".

-

ECM: Refer to EC-66, "CONSULT Function".

Are the memories erased? YES >> Inspection End

NO >> Check the items indicated by the self-diagnosis.

Diagnosis and repair work flow

Diagnosis and repair work flow

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.COLLECT INFORMATION FROM THE CUSTOMER

Get detailed information from the customer about the symptom

(the condition and the environment when the

in ...

Other materials:

Basic inspection

Diagnosis and repair workflow

Work flow

Overall sequence

Detailed flow

1.Obtain information about symptom

Interview the customer to obtain as much information as possible about the

conditions and environment under

which the malfunction occurred.

>> GO TO 2.

2.Check symptom

...

Diagnosis and repair workflow

Work flow

Overall sequence

Detailed flow

1. Obtain information about symptom

Interview the customer to obtain as much information as possible about the

conditions and environment under

which the malfunction occurred.

>> GO TO 2.

2. Confirm concern

Check the malfunction on the veh ...

Brake pedal position switch

Component Function Check

1.CHECK BRAKE PEDAL POSITION SWITCH FUNCTION

With CONSULT

Turn ignition switch ON.

Select “ENGINE” using CONSULT.

Select “BRAKE SW1” in “DATA MONITOR” mode.

Check “BRAKE SW1” indication under the following conditions.

...