Nissan Sentra Service Manual: Brake pedal position switch

Component Function Check

1.CHECK BRAKE PEDAL POSITION SWITCH FUNCTION

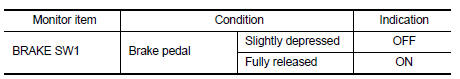

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select “ENGINE” using CONSULT.

- Select “BRAKE SW1” in “DATA MONITOR” mode.

- Check “BRAKE SW1” indication under the following conditions.

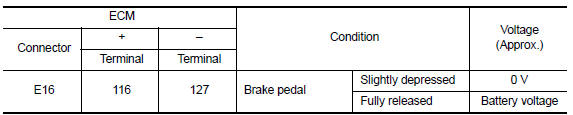

Without CONSULT

Without CONSULT

- Turn ignition switch ON.

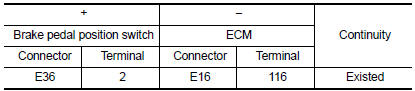

- Check the voltage between ECM harness connector terminals under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-446, "Diagnosis Procedure".

Diagnosis Procedure

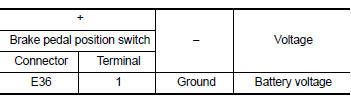

1.CHECK BRAKE PEDAL POSITION SWITCH POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect brake pedal position switch harness connector.

- Turn ignition switch ON.

- Check the voltage between brake pedal position switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

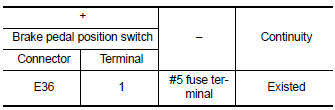

2.CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT

- Pull out #5 fuse.

- Check that the fuse is not fusing.

- Check the continuity between stop lamp switch harness connector and fuse terminal.

- Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> Check power supply circuit for 12V battery power supply.

NO >> Repair or replace error-detected parts.

3.CHECK BRAKE PEDAL POSITION SWITCH INPUT SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between brake pedal position switch harness connector and ECM harness connector.

- Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK BRAKE PEDAL POSITION SWITCH

Check brake pedal position switch. Refer to EC-447, "Component Inspection (Brake Pedal Position Switch)" Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Replace brake pedal position switch. Refer to BR-22, "Exploded View".

Component Inspection (Brake Pedal Position Switch)

1.CHECK BRAKE PEDAL POSITION SWITCH-I

- Turn ignition switch OFF.

- Disconnect brake pedal position switch harness connector.

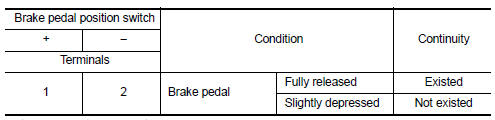

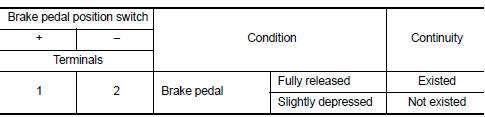

- Check the continuity between brake pedal position switch terminals under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK BRAKE PEDAL POSITION SWITCH-II

- Adjust brake pedal position switch installation. Refer to BR-15, "Adjustment".

- Check the continuity between brake pedal position switch terminals under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace brake pedal position switch. Refer to BR-22, "Exploded View".

Sensor power supply 2 circuit

Sensor power supply 2 circuit

Description

ECM supplies a voltage of 5.0 V to some of the sensors systematically divided

into 2 groups, respectively.

Accordingly, when a short circuit develops in a sensor power source, a

ma ...

ASCD Indicator

ASCD Indicator

Component Function Check

1.CHECK ASCD INDICATOR FUNCTION

Check ASCD indicator under the following conditions.

ASCD INDICATOR

CONDITION

SPECIFICATION

CRUISE LAMP

Ig ...

Other materials:

Oil seal

Valve oil seal : Removal and Installation

REMOVAL

Rotate crankshaft, and set piston whose valve oil seal is to be removed

to TDC. This will prevent valve

from dropping into cylinder.

CAUTION:

When rotating crankshaft, be careful to avoid scarring front cover with

timing chain.

Re ...

Sensor power supply 2 circuit

Description

ECM supplies a voltage of 5.0 V to some of the sensors systematically divided

into 2 groups, respectively.

Accordingly, when a short circuit develops in a sensor power source, a

malfunction may occur simultaneously

in the sensors belonging to the same group as the shorted-circui ...

How to use the touch-screen

CAUTION

The glass display screen may break if it

is hit with a hard or sharp object. If the

glass screen breaks, do not touch it.

Doing so could result in an injury.

To clean the display, never use a rough

cloth, alcohol, benzine, thinner or any

kind of solvent or paper towel with a

chemic ...