Nissan Sentra Service Manual: Basic inspection

Diagnosis and repair workflow

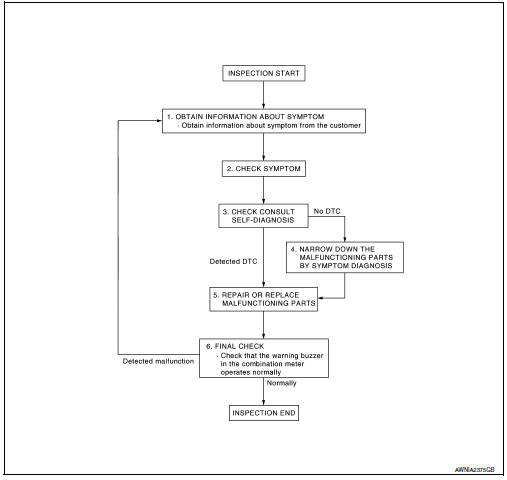

Work flow

Overall sequence

Detailed flow

1.Obtain information about symptom

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

>> GO TO 2.

2.Check symptom

- Check the symptom based on the information obtained from the customer.

- Check if any other malfunctions are present.

>> Go to 3.

3.Check consult self-diagnosis results

Connect consult and perform self-diagnosis. Refer to mwi-26, "dtc index".

Are self-diagnosis results normal? Yes >> go to 4.

No >> go to 5.

4.Narrow down malfunctioning parts by symptom diagnosis

Perform symptom diagnosis and narrow down the malfunctioning parts.

>> Go to 5.

5.Repair or replace malfunctioning parts

Repair or replace malfunctioning parts.

Note:

If dtc is displayed, erase dtc after repairing or replacing malfunctioning parts.

>> Go to 6.

6.Final check

Check that the warning buzzer in the combination meter operates normally.

Does it operate normally? Yes >> inspection end.

No >> go to 1.

Wiring diagram

Wiring diagram

Meter system

Wiring diagram

Compass

Wiring diagram

...

Other materials:

License plate lamp

Removal and Installation

REMOVAL

Remove the license lamp finisher. Refer to EXT-44, "Removal and

Installation".

Disconnect the harness connector (A) from the license plate

lamp (1).

Release pawl and remove.

: Pawl

INSTALLATION

Installation is in the reverse order of ...

Service Notice and Precautions for TPMS

WARNING:

Radio waves could adversely affect electric medical equipment. Those

who use a pacemaker should

contact the electric medical equipment manufacturer for the possible influences

before use.

Low tire pressure warning lamp blinks for 1 minute, then turns ON when

occurring any malfu ...

F.M.V.S.S./C.M.V.S.S. certification label

The Federal/Canadian Motor Vehicle Safety

Standard (F.M.V.S.S./C.M.V.S.S.) certification label

is affixed as shown. This label contains valuable

vehicle information, such as: Gross Vehicle

Weight Ratings (GVWR), Gross Axle Weight

Rating (GAWR), month and year of manufacture,

Vehicle Identi ...