Nissan Sentra Service Manual: Diagnosis and repair workflow

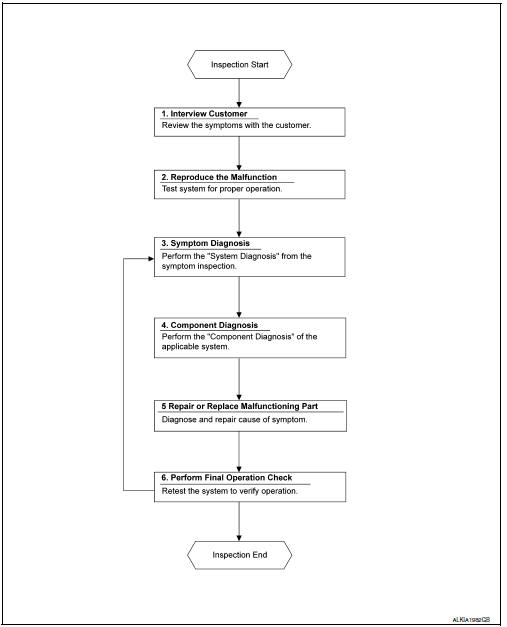

Work flow

Overall sequence

Detailed flow

1. Obtain information about symptom

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

>> GO TO 2.

2. Confirm concern

Check the malfunction on the vehicle that the customer describes.

Inspect the relation of the symptoms and the condition when the symptoms occur.

>> Go to 3.

3. Identify the malfunctioning system with symptom diagnosis

Use Symptom diagnosis from the symptom inspection result in step 2 and then identify where to start performing the diagnosis based on possible causes and symptoms.

>> GO TO 4.

4. Perform the component diagnosis of the applicable system

Perform the diagnosis with Component diagnosis of the applicable system.

>> GO TO 5.

5. Repair or replace the malfunctioning parts

Repair or replace the specified malfunctioning parts.

>> Go to 6.

6. Final check

Check that malfunctions are not reproduced when obtaining the malfunction information from the customer, referring to the symptom inspection result in step 2.

Are the malfunctions corrected? Yes >> inspection end.

No >> go to 3.

Basic inspection

Basic inspection

...

Inspection and adjustment

Inspection and adjustment

Additional service when replacing control unit

Additional service when replacing control unit : description

Memory reset procedure

Please observe the following instructions at confirming the moo ...

Other materials:

P099C Shift solenoid G

DTC Logic

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P099C

SHIFT SOLENOID G

(Shift Solenoid G Control Circuit

High)

The TCM high clutch & reverse brake solenoid

valve current monitor reading is 200 mA ...

Precaution

Precaution for supplemental restraint system (srs) "air bag" and "seat belt

pre-tensioner"

The Supplemental Restraint System such as ą▓ąéčÜAIR BAGą▓ąéč£ and ą▓ąéčÜSEAT BELT

PRE-TENSIONERą▓ąéč£, used along

with a front seat belt, helps to reduce the risk or severity of injur ...

U1000 Can comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real-time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent malfunction

detection ability.

Many electronic control units are equipped onto a vehicle, an ...