Nissan Sentra Service Manual: Differential side oil seal

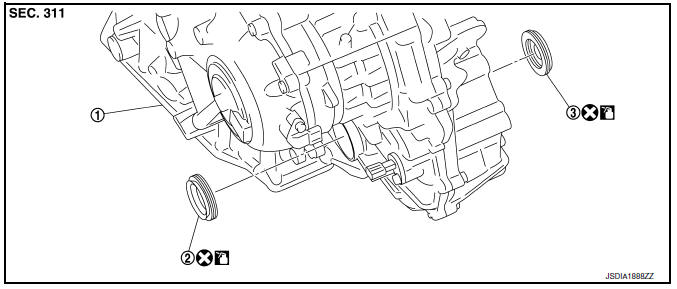

Exploded View

- Transaxle assembly

- Differential side oil seal (left side)

- Differential side oil seal (right side)

: Vehicle front

: Vehicle front

: Always replace after every

: Always replace after every

disassembly.

: Genuine NISSAN CVT Fluid NS-3

: Genuine NISSAN CVT Fluid NS-3

Removal and Installation

REMOVAL

NOTE:

Cap or plug openings to prevent fluid from spilling.

- Remove the front drive shaft (RH/LH). Refer to FAX-21, "6M/T : Removal and Installation (RH)"(RH), FAX- 18, "6M/T : Removal and Installation (LH)"(LH) and FAX-26, "EXCEPT 6M/T : Removal and Installation" (Except 6M/T).

- Use oil seal remover or a similar means and remove the differential side oil seal.

CAUTION:

When removing the differential side oil seal, be careful not to scratch the oil seal mounting surfaces of the transaxle case and converter housing.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse differential side oil seal.

- Apply Genuine NISSAN CVT Fluid NS-3 to the differential side oil seal lip and around the oil seal.

- When inserting the drive shaft, be sure to use a protector

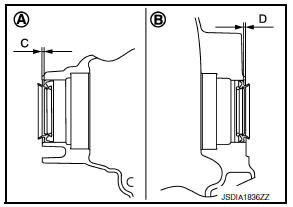

Using Tool, drive the differential side oil seal in until the amount of oil seal projection from the case edge matches dimensions (C) and (D).

Tool number : KV38107900

CAUTION:

Be careful not to scratch the lip of the differential side oil seal when press-fitting it.

(A) : Differential side oil seal (LH)

(B) : Differential side oil seal (RH)

Dimension “C” :Height difference from case end surface is within 1.8 ± 0.5 mm (0.071 ± 0.020 in).

Dimension “D” :Height difference from case end surface is within 1.8 ± 0.5 mm (0.071 ± 0.020 in).

NOTE:

The reference is the pull-in direction of the differential side oil seal.

Drift to be used:

| Location | Commercial Service Tools |

| Transaxle case side | Commercial service tool with outer dia. 56 mm (2.20 in) and inner dia. 50 mm (1.97 in) |

| Converter housing side |

Inspection and Adjustment

INSPECTION AFTER INSTALLATION

Drive the vehicle and check visually that there is no leakage of CVT fluid.

ADJUSTMENT AFTER INSTALLATION

Adjust CVT fluid level. Refer to TM-251, "Adjustment".

Output speed sensor

Output speed sensor

Exploded View

Transaxle assembly

Output speed sensor

O-ring

: Vehicle front

: Always replace after every

disassembly.

: NВ·m (kg-m, in-lb)

: Genuine NISSAN CVT Fluid NS-3

R ...

Water hose

Water hose

Exploded View

Water outlet

Heater thermostat assembly

Hose clamp

CVT oil warmer

Water hose

To thermostat housing

To engine oil cooler

: Always replace after every

disass ...

Other materials:

Connecting procedure

NOTE:

The connecting procedure must be performed

when the vehicle is stationary. If the

vehicle starts moving during the procedure,

the procedure will be cancelled.

To connect a phone to the Bluetooth® Hands-

Free Phone System:

Press the SETTING button.

Use the TUNE/FOLDER knob to s ...

Front fog lamp

Aiming adjustment

PREPARATION BEFORE ADJUSTING

The fog lamp is a semi-sealed beam type which uses a replaceable halogen

bulb. Before performing aiming

adjustment procedure, check the following:

Ensure all tires are inflated to correct pressure.

Place vehicle and screen on level surface.

...

Event Data Recorders (EDR)

This vehicle is equipped with an Event Data Recorder

(EDR). The main purpose of an EDR is to

record, in certain crash or near crash-like situations,

such as an air bag deployment or hitting a

road obstacle, data that will assist in understanding

how a vehicle’s systems performed. The EDR

is ...