Nissan Sentra Service Manual: Shift lock system

Component Function Check

1.CHECK SHIFT LOCK OPERATION (PART 1)

- Turn ignition switch ON.

- Shift the selector lever to park “P” position.

- Attempt to shift the selector lever to any other position with the brake pedal released.

Can the selector lever be shifted to any other position? YES >> Go to TM-241, "Diagnosis Procedure".

NO >> GO TO 2.

2.CHECK SHIFT LOCK OPERATION (PART 2)

Attempt to shift the selector lever to any other position with the brake pedal depressed.

Can the selector lever be shifted to any other position? YES >> Inspection End.

NO >> Go to TM-241, "Diagnosis Procedure".

Diagnosis Procedure

Regarding Wiring Diagram information, refer to TM-136, "Wiring Diagram".

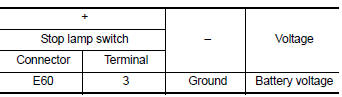

1.CHECK POWER SOURCE (PART 1)

- Turn ignition switch OFF.

- Disconnect stop lamp switch connector.

- Turn ignition switch ON.

- Check the voltage between the stop lamp switch harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> GO TO 9.

2.CHECK STOP LAMP SWITCH MOUNTING POSITION

Check stop lamp switch mounting position. Refer to BR-15, "Adjustment".

Is the inspection result normal? YES >> GO TO 3.

NO >> Adjust stop lamp switch mounting position.

3.CHECK STOP LAMP SWITCH

Check stop lamp switch. Refer to TM-243, "Component Inspection (Stop Lamp Switch)".

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace stop lamp switch.

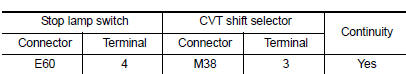

4.CHECK CIRCUIT BETWEEN STOP LAMP SWITCH AND CVT SHIFT SELECTOR (PART 1)

- Disconnect CVT shift selector connector

- Check the continuity between the stop lamp switch harness connector terminal and the CVT shift selector harness connector terminal.

Is the inspection

Is the inspection

result normal?

YES >> GO TO 5.

NO >> Repair or replace damaged parts.

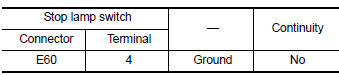

5.CHECK CIRCUIT BETWEEN STOP LAMP SWITCH AND CVT SHIFT SELECTOR (PART 2)

Check the continuity between the stop lamp switch harness connector terminal and ground.

Is the inspection

Is the inspection

result normal?

YES >> GO TO 6.

NO >> Repair or replace damaged parts.

6.CHECK GROUND CIRCUIT

Check the continuity between the CVT shift selector harness connector terminal and ground.

Is the inspection

Is the inspection

result normal?

YES >> GO TO 7.

NO >> Repair or replace damaged parts.

7.CHECK PART POSITION SWITCH

- Disconnect park position switch connector.

- Check park position switch. Refer to TM-243, "Component Inspection (Park Position Switch)".

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair or replace damaged parts.

8.CHECK SHIFT LOCK SOLENOID

- Disconnect shift lock solenoid connector.

- Check shift lock solenoid. Refer to TM-243, "Component Inspection (Shift Lock Solenoid)".

Is the inspection result normal? YES >> GO TO 9.

NO >> Repair or replace damaged parts.

9.DETECT MALFUNCTIONING ITEM

Check the following items:

- Open or short circuit of the harness between ignition switch and stop lamp switch connector. Refer to PG-20, "Wiring Diagram — Ignition Power Supply —"

- Ignition switch

- 10A fuse [No.5, fuse block (J/B)]. Refer to PG-47, "Terminal Arrangement".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Repair or replace damaged parts.

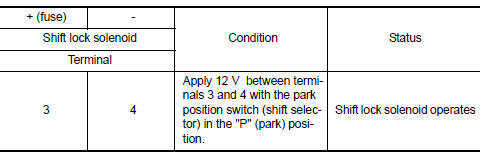

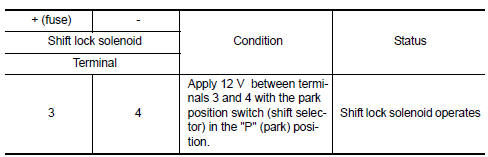

Component Inspection (Shift Lock Solenoid)

1.CHECK SHIFT LOCK SOLENOID

Apply voltage to terminals of shift lock solenoid and park position switch (shift selector) connector and check that shift lock solenoid is activated.

CAUTION:

- Connect a fuse between the terminals when applying voltage.

- Never cause shorting between terminals.

Is the inspection

Is the inspection

result normal?

YES >> Inspection End.

NO >> Replace CVT shift selector. Refer to TM-253, "Removal and Installation".

Component Inspection (Park Position Switch)

1.CHECK PARK POSITION SWITCH (SHIFT SELECTOR)

Apply voltage to terminals of shift lock solenoid and park position switch (shift selector) connector and check that shift lock solenoid is activated.

CAUTION:

- Connect a fuse between the terminals when applying voltage.

- Never cause shorting between terminals.

Is the inspection

Is the inspection

result normal?

YES >> Inspection End.

NO >> Replace CVT shift selector. Refer to TM-253, "Removal and Installation".

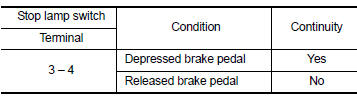

Component Inspection (Stop Lamp Switch)

1.CHECK STOP LAMP SWITCH

Check the continuity between the stop lamp switch connector terminals.

Is the inspection

Is the inspection

result normal?

YES >> Inspection End.

NO >> Replace stop lamp switch. Refer to BR-22, "Exploded View".

Shift position indicator circuit

Shift position indicator circuit

Component Parts Function Inspection

1.CHECK SHIFT POSITION INDICATOR

Start the engine.

Shift selector lever.

Check that the selector lever position and the shift position indicator

on the ...

Symptom diagnosis

Symptom diagnosis

CVT CONTROL SYSTEM

Symptom Table

The diagnosis item number indicates the order of check. Start checking in the

order from 1.

...

Other materials:

Precaution for work

When removing or disassembling each component, be careful not to damage

or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

When removing (disengaging) components with a screwdriver or similar

tool, be sure to wrap the component

with a ...

Diagnosis system (bcm) (with intelligent

key system)

Common item

Common item : consult function (bcm -

common item)

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BCM.

Direct Diagnostic Mode

Description

ECU identification

The BCM part number is displayed.

Self Diagnostic Result

...

Service Notice or Precautions for Steering System

In case of removing steering gear assembly, make the final

tightening with grounded and unloaded vehicle

condition, and then check wheel alignment.

Observe the following precautions when disassembling.

Before disassembly, thoroughly clean the outside of the

unit.

...