Nissan Sentra Service Manual: P099B Shift solenoid G

DTC Logic

DTC DETECTION LOGIC

| DTC | CONSULT screen terms (Trouble diagnosis content) | DTC detection condition | Possible causes |

| P099B | SHIFT SOLENOID G (Shift Solenoid G Control Circuit Low) | The TCM high clutch & reverse brake solenoid

valve current monitor reading is 200 mA or

less continuously for 200 msec or more under

the following diagnosis conditions: Diagnosis conditions

|

|

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another “DTC CONFIRMATION PROCEDURE” occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

- Start the engine and wait for 5 seconds or more.

- Check the first trip DTC.

Is “P099B” detected? YES >> Go to TM-214, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

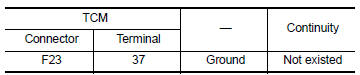

1.CHECK CIRCUIT BETWEEN TCM AND CVT UNIT

- Turn ignition switch OFF.

- Disconnect TCM connector and CVT unit connector.

- Check continuity between TCM harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace malfunctioning parts.

2.CHECK HIGH CLUTCH & REVERSE BRAKE SOLENOID VALVE

Check high clutch & reverse brake solenoid valve. Refer to TM-214, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Repair or replace malfunctioning parts.

Component Inspection

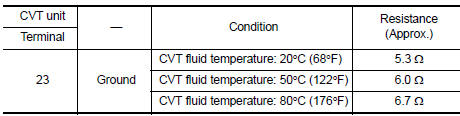

1.CHECK HIGH CLUTCH & REVERSE BRAKE SOLENOID VALVE

Check resistance between CVT unit connector terminal and ground.

Is the inspection result normal? YES >> INSPECTION END

NO >> There is a malfunction of high & reverse brake solenoid valve. Replace transaxle assembly. Refer to TM-283, "Removal and Installation".

P0999 Shift solenoid F

P0999 Shift solenoid F

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P0999

SHIFT SOLENOID F

(Shift Solenoid F ...

P099C Shift solenoid G

P099C Shift solenoid G

DTC Logic

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P099C

SHIFT SOLENOID G

(Shift Solenoid G Control Circuit

H ...

Other materials:

Steering knuckle

Exploded View

Steering knuckle

Splash guard

Wheel stud

Wheel hub and bearing

Disc brake rotor

Wheel hub lock nut

Nut retainer

Cotter pin

Removal and Installation

REMOVAL

Remove the wheel and tire using power tool. Refer to WT-47, "Exploded

View".

Remove ...

Front combination lamp

Exploded View

Large cover (not serviceable)

Small cover (not serviceable)

Front combination lamp

Halogen lamp bulb (high beam)

Turn signal lamp bulb

Turn signal lamp bulb socket

LED harness connector

Halogen lamp bulb (high beam)

harness connector

Halogen lamp bulb (low bea ...

Diagnosis system (ECM)

Diagnosis description : 1st trip detection

logic and two trip detection logic

When a malfunction is detected for the first time, 1st trip DTC and 1st trip

Freeze Frame data are stored in the

ECM memory. The MIL will not illuminate at this stage. <1st trip>

If the same malfunction is dete ...