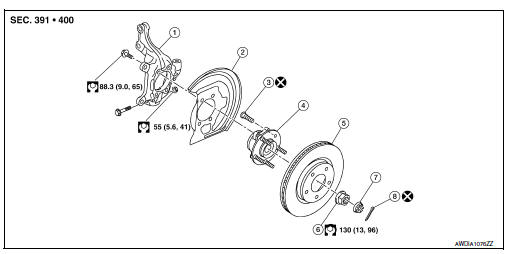

Nissan Sentra Service Manual: Steering knuckle

Exploded View

- Steering knuckle

- Splash guard

- Wheel stud

- Wheel hub and bearing

- Disc brake rotor

- Wheel hub lock nut

- Nut retainer

- Cotter pin

Removal and Installation

REMOVAL

- Remove the wheel and tire using power tool. Refer to WT-47, "Exploded View".

- Remove the nut and disconnect the steering outer socket from the steering knuckle. Refer to ST-14, "Removal and Installation".

- Remove the nut and bolt from the lower ball joint. Disconnect the steering knuckle from the transverse link.

- Remove the wheel hub and bearing from the steering knuckle. Refer to FAX-8, "Removal and Installation".

- Remove the splash guard from the steering knuckle.

- Suspend the drive shaft with suitable wire.

- Remove the lower strut nuts and bolts (

). Refer to FSU-8, "Exploded View".

- Remove the steering knuckle.

- Inspect the components. Refer to FSU-15, "Inspection".

INSTALLATION

Installation is in the reverse order of the removal.

CAUTION:

Do not reuse cotter pin.

- Complete the inspection. Refer to FSU-15, "Inspection".

Inspection

INSPECTION AFTER REMOVAL

Check the following items, and replace the part if necessary.

- Check components for deformation, cracks, and other damage.

- Check boots of transverse link and steering outer socket ball joint for breakage, axial end play, and swing torque.

- Transverse link: Refer to FSU-10, "Inspection".

- Steering outer socket: Refer to ST-8, "Inspection".

INSPECTION AFTER INSTALLATION

- Check the wheel sensor harness to be sure the connectors are fully seated.

- Check the wheel alignment. Refer to FSU-6, "Inspection".

Front stabilizer

Front stabilizer

Exploded View

Stabilizer bar

Stabilizer clamp

Stabilizer bushing

Stabilizer connecting rod

Front coil spring and strut

Front suspension member

Front

Removal and Installation

RE ...

Unit removal and installation

Unit removal and installation

Front suspension member

Exploded View

Upper link

Front suspension member

Member stay

Front

Upper link

Front suspension member

Member stay

Front

Removal and Installat ...

Other materials:

Headlining

Exploded View

STANDARD ROOF

Headlining

Assist grip

Map lamp bracket

Sun visor (RH)

Sun visor cover

Sun visor holder

Map lamp

Sun visor (LH)

Interior room lamp

Assist grip cap

Headlining clip

Metal clip

Pawl

Metal clip

Sunroof

Headlining

Assist grip

...

Eps branch line circuit

Diagnosis Procedure

1.Check connector

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the eps control unit for damage,

bend and loose connection (unit

side and connector side).

Is the inspection result norm ...

Symptom diagnosis

Audio system

Symptom table

Related to audio

Related to hands-free phone

Before performing diagnosis, confirm that the cellular phone being used

by the customer is compatible with

the vehicle.

It is possible that a malfunction is occurring due to a version change

of the p ...