Nissan Sentra Service Manual: P099C Shift solenoid G

DTC Logic

| DTC | CONSULT screen terms (Trouble diagnosis content) | DTC detection condition | Possible causes |

| P099C | SHIFT SOLENOID G (Shift Solenoid G Control Circuit High) | The TCM high clutch & reverse brake solenoid

valve current monitor reading is 200 mA or

less continuously for 200 msec or more under

the following diagnosis conditions: Diagnosis conditions

|

|

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another “DTC CONFIRMATION PROCEDURE” occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

- Start the engine and wait for 5 seconds or more

- Check the first trip DTC.

Is “P099C” detected? YES >> Go to TM-216, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

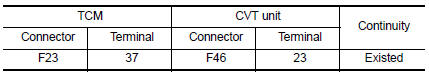

1.CHECK CIRCUIT BETWEEN TCM AND CVT UNIT

- Turn ignition switch OFF.

- Disconnect TCM connector and CVT unit connector.

- Check continuity between TCM harness connector terminal and CVT unit harness connector terminal.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace malfunctioning parts.

2.CHECK HIGH CLUTCH & REVERSE BRAKE SOLENOID VALVE

Check high clutch & reverse brake solenoid valve. Refer to TM-216, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Repair or replace malfunctioning parts.

Component Inspection

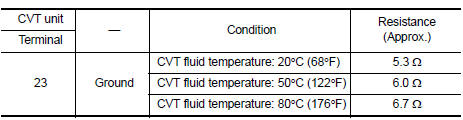

1.CHECK HIGH CLUTCH & REVERSE BRAKE SOLENOID VALVE

Check resistance between CVT unit connector terminal and ground.

Is the inspection result normal? YES >> INSPECTION END

NO >> There is a malfunction of high & reverse brake solenoid valve. Replace transaxle assembly. Refer to TM-283, "Removal and Installation".

P099B Shift solenoid G

P099B Shift solenoid G

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P099B

SHIFT SOLENOID G

(Shift Solenoid G ...

P1586 G Sensor

P1586 G Sensor

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P1586

G Sensor

(Gravity Sensor Circuit)

...

Other materials:

Steering wheel turning force is heavy or light

Description

Steering wheel turning force is heavy or light.

Diagnosis Procedure

1.PERFORM SELF-DIAGNOSIS

With CONSULT

Turn the ignition switch OFF to ON.

Perform EPS self-diagnosis.

Is any DTC detected?

YES >> Check the DTC. Refer to STC-14, "DTC Index".

NO & ...

Unit disassembly and assembly

Moonroof unit assembly

Exploded view

Drain assembly

Glass lid

Weatherstrip

Moonroof rail assembly

Drain hose front (RH)

Moonroof motor assembly

Drain hose front (LH)

Side bracket (LH)

Drain hose rear (LH)

Sunshade stopper (LH)

Sunshade

Sunshade stopper (RH)

Drain hos ...

Starter motor drive control

STARTER MOTOR DRIVE CONTROL : System Description

SYSTEN DIAGRAM

*1: CVT models

*2: M/T models

INPUT/OUTPUT SIGNAL CHART

Sensor

Input signal to ECM

ECM function

Actuator

Crankshaft position sensor (POS)

Engine speed

Piston position

Starter ...