Nissan Sentra Service Manual: P1586 G Sensor

DTC Logic

DTC DETECTION LOGIC

| DTC | CONSULT screen terms (Trouble diagnosis content) | DTC detection condition | Possible causes |

| P1586 | G Sensor (Gravity Sensor Circuit) | When the following diagnosis conditions are

satisfied and the detection conditions are satisfied

twice in the same DC: Diagnosis conditions

Detection condition

|

|

| When the following diagnosis conditions are satisfied and the detection conditions are satisfied twice in the same DC: Diagnosis conditions

Detection condition

|

NOTE:

DC stands for “DRIVING CYCLE” and indicates a series of driving cycle of “Ignition switch OFF → ON → driving → OFF”.

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another “DTC CONFIRMATION PROCEDURE” occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT

With CONSULT

- With CONSULT

- Drive the vehicle for 10 seconds or more.

- Stop the vehicle.

CAUTION:

Never stop the engine.

- Repeat step 2 through 3.

- Check the DTC.

Is “P1586” detected? YES >> Go to TM-218, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

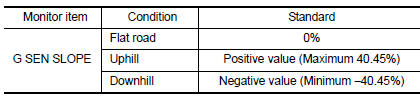

1.CHECK G SENSOR SIGNAL

With CONSULT

With CONSULT

- Park the vehicle on a level surface.

- Turn ignition switch ON.

- Select “Data Monitor” in “TRANSMISSION”.

- Select “G SEN SLOPE”.

- Swing the vehicle and check if the value varies between −40.45% and 40.45%.

Is the inspection result normal? YES >> GO TO 2.

NO >> GO TO 3.

2.CALIBRATION OF G SENSOR (PART 1)

With CONSULT

With CONSULT

- Select “Self Diagnostic Results” in “TRANSMISSION”.

- Touch “Erase”.

>> Perform “CALIBRATION OF G SENSOR”. Refer to TM-147, "Work Procedure".

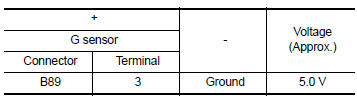

3.CHECK SENSOR POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect G sensor connector.

- Turn ignition switch ON.

- Check voltage between G sensor harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 8.

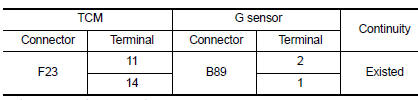

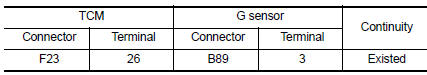

4.CHECK CIRCUIT BETWEEN TCM AND G SENSOR (PART 1)

- Turn ignition switch OFF.

- Disconnect TCM connector.

- Check continuity between TCM harness connector terminals and G sensor harness connector terminals.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace malfunctioning parts.

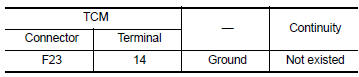

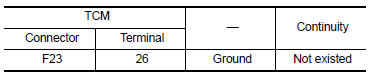

5.CHECK CIRCUIT BETWEEN TCM AND G SENSOR (PART 2)

Check continuity between TCM harness connector terminal and ground.

The inspection result normal? Yes >> go to 6.

No >> repair or replace malfunctioning parts.

6.Check g sensor

- Remove g sensor. Refer to tm-265, "removal and installation".

- Connect the all connectors.

- Turn ignition switch on.

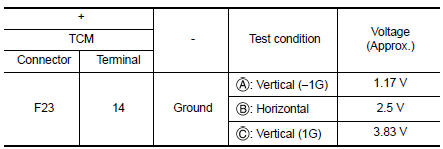

- Check voltage between TCM connector terminal and ground.

: Direction of gravitational

: Direction of gravitational

force

Is the inspection result normal? Yes >> go to 7.

No >> replace g sensor. Refer to tm-265, "removal and installation".

7.Calibration of g sensor (part 2)

With CONSULT

With CONSULT

- Install G sensor. Refer to TM-265, "Removal and Installation".

- Select “Self Diagnostic Results” in “TRANSMISSION”.

- Touch “Erase”.

>> Perform “CALIBRATION OF G SENSOR”. Refer to TM-147, "Work Procedure".

8.CHECK SENSOR POWER SUPPLY CIRCUIT (PART 1)

- Turn ignition switch OFF.

- Disconnect TCM connector.

- Check continuity between TCM harness connector terminal and G sensor harness connector terminal

Is the inspection result normal? YES >> GO TO 9.

NO >> Repair or replace malfunctioning parts.

9.CHECK SENSOR POWER SUPPLY CIRCUIT (PART 2)

Check continuity between TCM harness connector terminal and ground.

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Repair or replace malfunctioning parts.

P099C Shift solenoid G

P099C Shift solenoid G

DTC Logic

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P099C

SHIFT SOLENOID G

(Shift Solenoid G Control Circuit

H ...

P1588 G Sensor

P1588 G Sensor

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P1588

G Sensor

(Gravity S ...

Other materials:

P1651 Starter motor relay

Description

ECM controls ON/OFF state of the starter relay, according to the engine and

vehicle condition. ECM transmits

a control signal to IPDM E/R by CAN communication.

Under normal conditions, ECM controls and maintains the starter relay in OFF

state during following condition:

Engi ...

System description

COMPONENT PARTS

Component Parts Location

Transaxle assembly

STRUCTURE AND OPERATION

Sectional View

3rd input gear

3rd-4th synchronizer hub assembly

4th input gear

5th input gear

5th-6th synchronizer hub assembly

6th input gear

Transaxle case

6th main gear

5 ...

Front drive shaft

6M/T

6M/T : Exploded View (LH)

Front drive shaft

Nut retainer

Cotter pin

Molykote M77

Front

6M/T : Removal and Installation (LH)

NOTE:

When removing components such as hoses, tubes, lines, etc., cap or plug

openings to prevent fluid from spilling.

REMOVAL

Remove the ...