Nissan Sentra Service Manual: Intake manifold

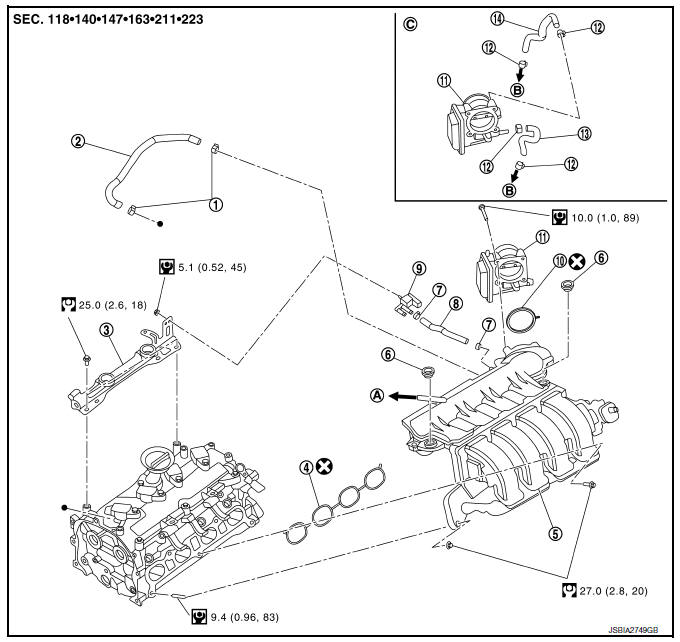

Exploded View

- Clamp

- PCV hose

- Bracket

- Intake manifold gasket

- Intake manifold

- Mount rubber

- Clamp

- EVAP hose

- EVAP canister purge volume control solenoid valve

- Electric throttle control actuator gasket

- Electric throttle control actuator

- Clamp

- Water hose

- Water hose

- To brake booster

- To water outlet

- Electric throttle control actuator exploded view

Removal and Installation

NOTE:

When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

REMOVAL

- Remove engine room cover. Refer to EM-46, "Exploded View".

- Remove air cleaner body. Refer to EM-25, "Exploded View".

- Disconnect the radiator hose (upper) from the water outlet. Refer to CO-15, "Exploded View".

- Disconnect water hoses from electric throttle control actuator

- Disconnect electric throttle control actuator harness connector.

- Remove electric throttle control actuator.

CAUTION:

- Handle carefully to avoid any shock to electric throttle control actuator.

- Do not disassemble electric throttle control actuator.

- Pull out oil level gauge.

CAUTION:

Cover the oil level gauge guide openings to avoid entry of foreign materials.

- Disconnect vacuum hose and EVAP hose from intake manifold.

- Disconnect PCV hose from intake manifold.

- Disconnect harness connectors from the runner control valve, runner control valve position sensor, and the tuning valve.

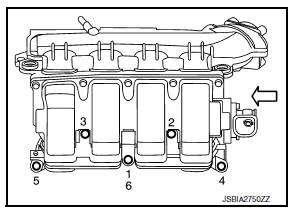

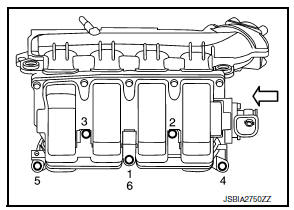

- Loosen intake manifold nuts and bolts in the reverse order as shown.

: Engine front

: Engine front

NOTE:

Disregard the numerical order No.6 in removal.

CAUTION:

Cover engine openings to avoid entry of foreign materials.

- Remove intake manifold and intake manifold gasket.

INSTALLATION

Installation is in the reverse order of removal.

Intake Manifold

- Securely install intake manifold gasket to the mounting groove of the intake manifold.

CAUTION:

Do not reuse intake manifold gasket.

- Install intake manifold with the following procedure:

- Tighten intake manifold nuts and bolts in the numerical order as shown.

- Tighten No. 1 bolt again.

- Tighten bolts of electric throttle control actuator equally and diagonally in several steps.

NOTE:

After installation, it is necessary to re-calibrate the electric throttle control actuator as follows:

- Perform “Throttle Valve Closed Position Learning” after repair when removing harness connector of the electric throttle control actuator. Refer to EC-139, "Description".

- Perform “Idle Air Volume Learning” after repair when replacing electric throttle control actuator. Refer to EC- 140, "Description".

INSPECTION AFTER INSTALLATION

Check for engine oil leaks and engine coolant leaks with engine at operating temperature and running at idle.

WARNING:

Do not touch engine immediately after stopping as engine is extremely hot.

Air cleaner and air duct

Air cleaner and air duct

Exploded View

Mass air flow sensor

Mass air flow gasket

Clamp

Air duct (suction side)

Resonator

Clamp

PCV hose

Clamp

Clamp

Air cleaner cover

Mounting rubber

Air cleaner f ...

Exhaust manifold

Exhaust manifold

Exploded View

CALIFORNIA

Air fuel ratio sensor

Exhaust manifold heat shield (upper)

Exhaust manifold and three way catalyst

Exhaust manifold heat shield (rear)

Exhaust manifold heat ...

Other materials:

Starting system (without intelligent key)

Wiring Diagram

...

Rear disc brake

BRAKE PAD

BRAKE PAD : Inspection

PAD WEAR

Check pad thickness from an inspection hole on caliper body. Check

using a scale if necessary.

Wear limit thickness : Refer to BR-55, "Rear Disc

Brake".

DISC ROTOR

DISC ROTOR : Inspection

APPERANCE

Check surface of disc rotor for unev ...

Recommended chemical products and sealants

Refer to the following chart for help in selecting the appropriate chemical

product or sealant.

Product Description

Purpose

Nissan North America

Part No. (USA)

Nissan Canada Part

No. (Canada)

Aftermarket Crossreference

Part Nos.

1

Rear View Mirror ...