Nissan Sentra Service Manual: Fuel level sensor signal circuit

Description

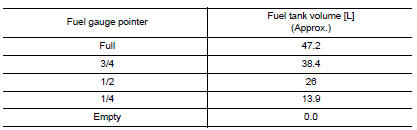

The fuel level sensor unit and fuel pump detects the approximate fuel level in the fuel tank and transmits the fuel level signal to the combination meter.

Component function check

1.Combination meter input signal

- Select meter/m&a on consult.

- Using FUEL METER of DATA MONITOR, compare the value of DATA MONITOR with fuel gauge pointer of combination meter.

Does the data monitor value approximately match the fuel gauge indication? YES >> Inspection End.

NO >> Replace combination meter. Refer to MWI-77, "Removal and Installation".

Diagnosis procedure

Regarding wiring diagram information, refer to mwi-28, "wiring diagram".

1.Check fuel level sensor circuit

- Turn ignition switch off.

- Disconnect combination meter connector and fuel level sensor unit connector.

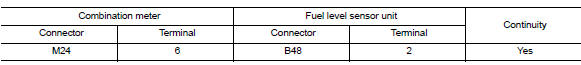

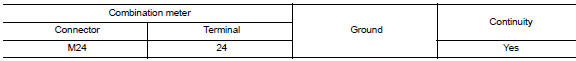

- Check continuity between combination meter harness connector and fuel level sensor unit harness connector.

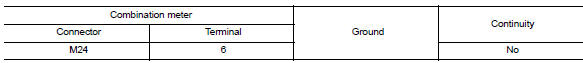

- Check continuity between combination meter harness connector and ground.

Is the inspection result normal? Yes >> go to 2.

No >> repair or replace harness or connector.

2.Check fuel level sensor ground circuit

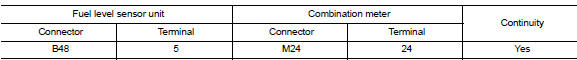

- Check continuity between fuel level sensor unit harness connector and combination meter harness connector.

- Check continuity between combination meter harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness or connector.

3.Check installation condition

Check fuel level sensor unit installation, and check whether the float arm interferes or binds with any of the internal components in the fuel tank.

Is the inspection result normal? Yes >> inspection end.

No >> install the fuel level sensor unit properly. Refer to fl-6, "removal and installation".

Component inspection

1.Remove fuel level sensor unit

Remove the fuel level sensor unit. Refer to fl-6, "removal and installation".

>> Go to 2.

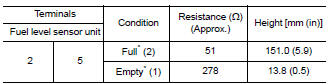

2.Check fuel level sensor unit

Check the resistance between fuel level sensor unit and fuel pump.

*: When float rod is in contact with stopper.

Is inspection result ok? Yes >> inspection end.

No >> replace fuel level sensor unit and fuel pump. Refer to fl-6, "removal and installation".

Illumination control switch signal circuit

Illumination control switch signal circuit

Diagnosis procedure

Regarding wiring diagram information, refer to mwi-28, "wiring diagram".

1.Check combination meter input signal

Turn ignition switch on.

Check voltage between the ...

Parking brake switch signal circuit

Parking brake switch signal circuit

Component function check

1.Check parking brake switch operation

Check that brake warning lamp in combination meter turns on/off when parking

brake is actuated.

Is the inspection result normal?

...

Other materials:

Power supply and ground circuit

Av control unit

Av control unit : diagnosis procedure

Regarding wiring diagram information, refer to av-331, "wiring diagram".

1.Check fuse

Check that the following fuses are not blown.

Are the fuses blown?

Yes >> replace the blown fuse after repairing the affected circuit. ...

Trip computer

When the ignition switch is placed in the ON

position, the modes of the trip

computer can be

selected by pressing the button on the

steering wheel. The following modes can be selected:

Trip A

Trip B

ECO Pedal Indicator

Instant fuel economy

Average fuel economy

Average speed

Dis ...

Front fog lamp

Removal and Installation

FOG LAMP

Removal

Position the fender protector aside. Refer to EXT-28, "FENDER PROTECTOR

: Removal and Installation

- Front Fender Protector".

Disconnect the harness connector from the front fog lamp.

Remove the screws and the front fog lamp.

Inst ...