Nissan Sentra Service Manual: Dtc/circuit diagnosis

U1000 can comm circuit

Description

Refer to LAN-7, "CAN COMMUNICATION SYSTEM : System Description".

Dtc logic

DTC DETECTION LOGIC

| CONSULT Display | DTC Detection Condition | Possible Cause |

| CAN COMM CIRCUIT [U1000] | When IPDM E/R cannot communicate with CAN communication signal continuously for 2 seconds or more | In CAN communication system, any item (or items) of

the following listed below is malfunctioning.

|

Diagnosis procedure

1. PERFORM SELF DIAGNOSTIC RESULT

- Turn ignition switch ON and wait for 2 second or more.

- Check “SELF-DIAG RESULTS” of IPDM E/R.

Is “CAN COMM CIRCUIT” displayed? YES >> Refer to LAN-16, "Trouble Diagnosis Flow Chart".

NO >> Refer to GI-39, "Intermittent Incident".

B2098 ignition relay on stuck

Dtc logic

DTC DETECTION LOGIC

| CONSULT Display | DTC Detection Condition | Possible Cause |

| IGN RELAY ON [B2098] | The ignition relay ON is detected for 1 second at ignition switch OFF (CPU monitors the status at the contact and excitation coil circuits of the ignition relay inside it) | IPDM E/R |

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

- Turn the power supply position to start under the following conditions and wait for at least 1 second.

CVT model

- CVT selector lever is in the P (Park) or N (Neutral) position.

- Depress the brake pedal

M/T model

- Selector lever is in the Neutral position

- Depress the clutch pedal

- Check “Self-diagnostic result” with CONSULT.

Is DTC detected? YES >> Refer to PCS-27, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis procedure

1. PERFORM SELF DIAGNOSTIC RESULT

Perform Self Diagnostic Result of IPDM E/R using CONSULT.

Is display history of DTC B2098 CRNT? YES >> Replace IPDM E/R. Refer to PCS-30, "Removal and Installation".

NO >> Refer to GI-39, "Intermittent Incident".

B2099 ignition relay off stuck

Dtc logic

DTC DETECTION LOGIC

| CONSULT Display | DTC Detection Condition | Possible Cause |

| IGN RELAY OFF [B2099] | The ignition relay OFF is detected for 1 second at ignition switch ON (CPU monitors the status at the contact and excitation coil circuits of the ignition relay inside it) | IPDM E/R |

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

- Turn the power supply position to start under the following conditions and wait for at least 1 second.

CVT model

- CVT selector lever is in the P (Park) or N (Neutral) position.

- Depress the brake pedal

M/T model

- Selector lever is in the Neutral position.

- Depress the clutch pedal

- Check “Self-diagnostic result” with CONSULT

Is DTC detected? YES >> Refer to PCS-28, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis procedure

1. PERFORM SELF DIAGNOSTIC RESULT

Perform Self Diagnostic Result of IPDM E/R using CONSULT.

Is display history of DTC B2099 CRNT? YES >> Replace IPDM E/R. Refer to PCS-30, "Removal and Installation".

NO >> Refer to GI-39, "Intermittent Incident".

Power supply and ground circuit

Diagnosis procedure

Regarding Wiring Diagram information, refer to PCS-21, "Wiring Diagram".

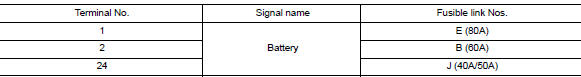

1. Check fuse and fusible links

Check that the following ipdm e/r fusible links are not blown.

Is the fusible link blown? Yes >> replace the blown fusible link after repairing the affected circuit.

No >> go to 2

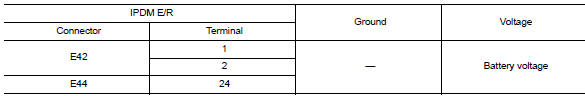

2. Check power supply circuit

- Disconnect ipdm e/r connector e42 and e44.

- Check voltage between ipdm e/r connector e42 and e44 and ground.

Is the inspection result normal? Yes >> go to 3

No >> repair harness or connectors.

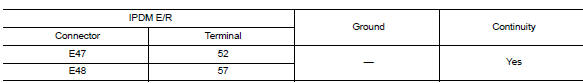

3. Check ground circuit

- Turn ignition switch OFF.

- Disconnect ipdm e/r connector e47 and e48.

- Check continuity between ipdm e/r connector e47 and e48 and ground.

Is the inspection result normal? Yes >> inspection end.

No >> repair harness or connectors.

Wiring diagram

Wiring diagram

Ipdm e/r (intelligent power distribution module engine room)

Wiring diagram

...

Removal and installation

Removal and installation

Ipdm e/r

Exploded view

Ipdm e/r

Ipdm e/r cover a

Ipdm e/r cover b

Removal and installation

Caution:

Ipdm e/r integrated relays are not serviceable and must not be removed

from unit.

...

Other materials:

P0524 Engine oil pressure

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0524

ENGINE OIL PRESSURE

(Engine oil pressure too low)

An EOP sensor signal voltage applied to

ECM remains lower than the specified ...

Fuel pump

Component Function Check

1.CHECK FUEL PUMP FUNCTION

Turn ignition switch ON.

Pinch fuel feed hose with

two fingers.

Fuel pressure pulsation should be felt on the fuel feed

hose for 1 second after ignition switch is turned ON.

Is the inspection result normal?

YES >> INSPECT ...

B0021 Side curtain air bag module LH

Description

DTC B0021 LH SIDE CURTAIN AIR BAG MODULE

The LH side curtain air bag module is wired to the air bag diagnosis sensor

unit. The air bag diagnosis sensor

unit will monitor for opens and shorts in detected lines to the LH side curtain

air bag module.

PART LOCATION

Refer to SRC-5, ...