Nissan Sentra Service Manual: P0524 Engine oil pressure

DTC Logic

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition | Possible cause |

| P0524 | ENGINE OIL PRESSURE (Engine oil pressure too low) | An EOP sensor signal voltage applied to ECM remains lower than the specified value continuously for 10 seconds or more when the engine speed is 1,000 rpm ore more. |

|

DTC CONFIRMATION PROCEDURE

CAUTION:

If “Diagnosis Procedure” is unfinished, be sure to perform Step 3 and 4.

1.PRECONDITIONING-1

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TEST CONDITION:

Before performing the following procedure, confirm that battery voltage is 11 V or more at idle.

>> GO TO 2.

2.PRECONDITIONING-2

Is “Diagnosis Procedure” of DTC P0524 finished? YES >> GO TO 5.

NO >> GO TO 3.

3.CHECK ENGINE OIL LEVEL

Check engine oil level. Refer to LU-7, "Inspection".

Is the inspection result normal? YES >> GO TO 4.

NO >> Proceed to EC-344, "Diagnosis Procedure".

4.CHECK ENGINE OIL PRESSURE

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select “DATA MONITOR” mode of “ENGINE” using CONSULT

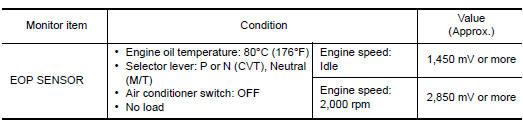

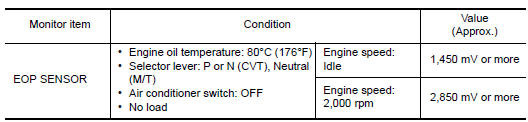

- Start the engine and check that “EOP SENSOR” changes, according to engine speeds.

Without CONSULT

Without CONSULT

Check engine oil pressure. Refer to LU-7, "Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Proceed to EC-344, "Diagnosis Procedure".

5.PERFORM DTC CONFIRMATION PROCEDURE

- Start engine and warm it up to normal operating temperature.

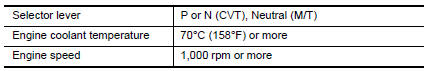

- Maintain the following conditions for about 10 consecutive seconds.

NOTE:

With engine speed set around 4,000 rpm, the phenomenon can be reproduced more easily.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-344, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK ENGINE OIL LEVEL

- Turn ignition switch OFF.

- Check engine oil level. Refer to LU-7, "Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> GO TO 4.

2.CHECK ENGINE OIL PRESSURE

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select “DATA MONITOR” mode of “ENGINE” using CONSULT.

- Start the engine and check that “EOP SENSOR” changes, according to engine speeds.

Without CONSULT

Without CONSULT

Check engine oil pressure. Refer to LU-7, "Inspection".

Is the inspection result normal? YES >> GO TO 3.

NO >> Check oil pump. Refer to LU-15, "Removal and Installation".

3.CHECK EOP SENSOR

Check EOP sensor. Refer to EC-342, "Component Inspection (EOP Sensor)".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Repair or replace error-detected parts.

4.CHECK ENGINE OIL LEAKAGE

Check engine oil leakage. Refer to LU-7, "Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

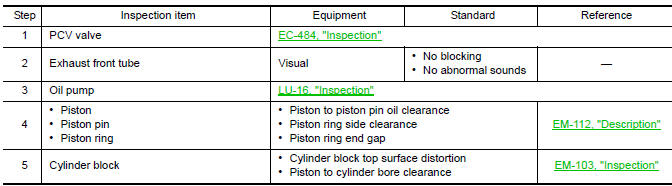

5.CHECK CAUSE OF ENGINE OIL CONSUMPTION

Check the following item.

>> Repair or replace error-detected parts.

Component Inspection (EOP Sensor)

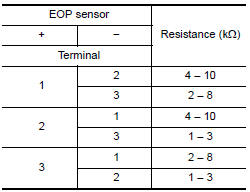

1.CHECK EOP SENSOR

- Turn ignition switch OFF.

- Disconnect EOP sensor harness connector

- Check the resistance between EOP sensor connector terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace EOP sensor. Refer to EM-94, "Exploded View".

P0520 EOP System

P0520 EOP System

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0520

EOP SENSOR/SWITCH

(Engine oil pr ...

P0603 ECM

P0603 ECM

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0603

ECM BACK UP CIRCUIT

[Internal co ...

Other materials:

Description

This vehicle has both new standard based on ISO* and previous standard

bolts/nuts. There are some differences

between these two types of bolts/ nuts; shape of the head, grade of strength,

hexagonal width across

flats and the standard tightening torque.

For guidance in discriminating, refer ...

Drinking alcohol/drugs and driving

WARNINGNever drive under the influence of alcohol

or drugs. Alcohol in the bloodstream reduces

coordination, delays reaction time

and impairs judgement. Driving after

drinking alcohol increases the likelihood

of being involved in an accident injuring

yourself and others. Add ...

C1704, C1705, C1706, C1707 Low tire pressure

DTC Logic

NOTE:

The Signal Tech II Tool (J-50190) can be used to perform the following

functions. Refer to the Signal Tech II

User Guide for additional information.

Activate and display TPMS transmitter IDs

Display tire pressure reported by the TPMS transmitter

Read TPMS DTCs

Register ...