Nissan Sentra Service Manual: Drive belt

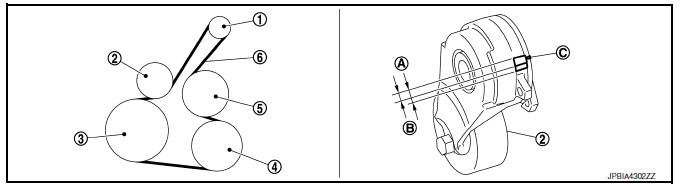

Exploded View

- Alternator

- Drive belt auto-tensioner

- Crankshaft pulley

- A/C compressor

- Water pump

- Drive belt

- Possible use range

- New drive belt range

- Indicator

Removal and Installation

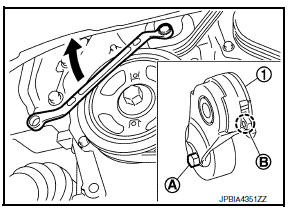

REMOVAL

- Remove the front fender protector (RH) front side bolts and clips. Refer to EXT-27, "FENDER PROTECTOR : Exploded View".

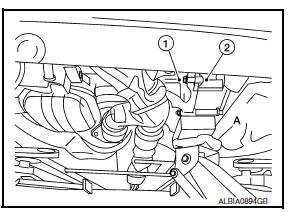

- Hold the hexagonal part (A) of drive belt auto-tensioner (1) with a wrench securely. Then move the wrench handle in the direction of arrow (loosening direction of drive belt auto-tensioner).

WARNING:

Avoid placing hand in a location where pinching may occur if the holding tool accidentally comes off.

- Insert a rod approximately 6 mm (0.24 in) in diameter into the hole (B) of the retaining boss to lock drive belt auto-tensioner.

- Keep drive belt auto-tensioner pulley arm locked after drive belt is removed.

- Remove drive belt.

INSTALLATION

- Install drive belt.

CAUTION:

- Confirm drive belt is completely set to pulleys.

- Check for engine oil and engine coolant, be sure they are not adhered to drive belt and each pulley groove.

- Release drive belt auto-tensioner, and apply tension to drive belt.

WARNING:

Avoid placing hand in a location where pinching may occur if the holding tool accidentally comes off.

- Turn crankshaft pulley clockwise several times to equalize tension between each pulley.

- Confirm tension of drive belt at indicator (notch on fixed side) is within the possible use range. Refer to EM-15, "Exploded View".

- Install the front fender protector (RH) front side bolts and clips. Refer to EXT-27, "FENDER PROTECTOR : Exploded View".

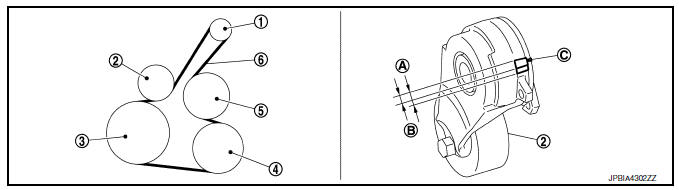

Inspection

- Alternator

- Drive belt auto-tensioner

- Crankshaft pulley

- A/C compressor

- Water pump

- Drive belt

- Possible use range

- New drive belt range

- Indicator

WARNING:

Perform this step when engine is stopped.

- Check that the indicator of drive belt auto-tensioner is within the possible use range.

NOTE:

- Check the drive belt auto-tensioner indication when the engine is cold.

- When new drive belt is installed, the indicator should be within the new drive belt range.

- Visually check entire drive belt for wear, damage or cracks.

- If the indicator is out of the possible use range or belt is damaged, replace drive belt.

Adjustment

Belt tension is not necessary, as it is automatically adjusted by drive belt auto-tensioner.

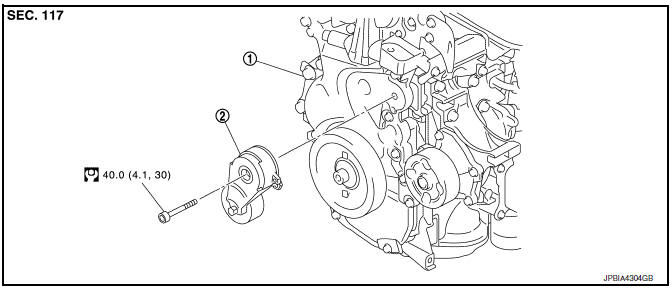

Exploded View

- Front cover

- Drive belt auto-tensioner

Removal and Installation

Removal

- Remove engine under cover. Refer to EXT-31, "ENGINE UNDER COVER : Exploded View".

- Remove engine room cover. Refer to EM-24, "Exploded View".

- Partially remove fender protector side cover (RH). Refer to EXT-27, "FENDER PROTECTOR : Exploded View".

- Remove drive belt. Refer to EM-15, "Exploded View".

- Support engine (1) and transaxle (2) using suitable jack (A).

CAUTION:

- Position a suitable jack under the engine and transaxle assembly as shown.

- Do not damage the front exhaust tube or transaxle oil pan with the jack.

- Remove upper torque rod and engine mounting insulator (RH). Refer to EM-82, "M/T : Exploded View" (for M/T) or EM-86, "CVT : Exploded View" (for CVT).

- Remove drive belt auto-tensioner.

Installation

Installation is in the reverse order of removal

CAUTION:

When installing drive belt auto-tensioner, be careful not to interfere with water pump pulley.

Spark plug

Spark plug

Exploded View

Ignition coil

Spark plug

Rocker cover

Removal and Installation

REMOVAL

Remove engine cover. Refer to EM-24, "Exploded View".

Remove ignition coil. Refer t ...

Air cleaner filter

Air cleaner filter

Exploded View

Mass air flow sensor

Mass air flow gasket

Clamp

Air duct (suction side)

Resonator

Clamp

PCV hose

Clamp

Clamp

Air cleaner cover

Mounting rubber

Air cleaner f ...

Other materials:

P0506 ISC System

Description

The ECM controls the engine idle speed to a specified level through the fine

adjustment of the air, which is let

into the intake manifold, by operating the electric throttle control actuator.

The operating of the throttle valve is

varied to allow for optimum control of the engine ...

Precaution

Precaution for supplemental restraint system (srs)

"air bag" and "seat belt pre-tensioner"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT

PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injur ...

Main line between dlc and hvac circuit

Diagnosis Procedure

1.Check harness continuity (open circuit)

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Disconnect the following harness connectors.

Ecm

A/c auto amp.

Check the continuity between the data link connector and the a/c ...