Nissan Sentra Service Manual: Diagnosis and repair workflow

Work Flow

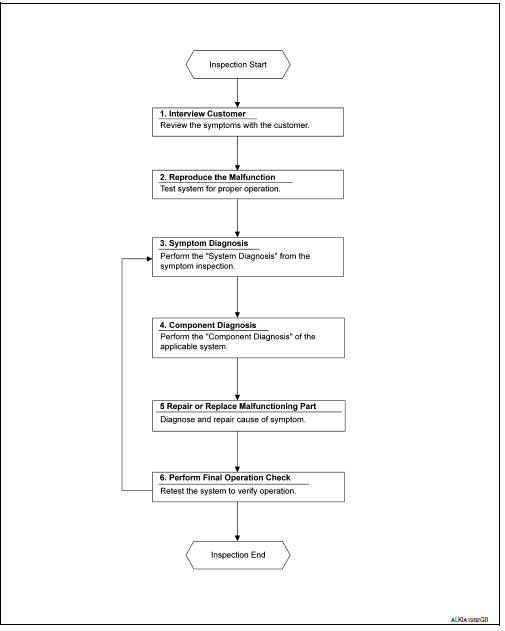

OVERALL SEQUENCE

DETAILED FLOW

1. OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

>> GO TO 2.

2. CONFIRM THE SYMPTOM

Check the malfunction on the vehicle that the customer describes.

Inspect the relation of the symptoms and the condition when the symptoms occur.

>> GO TO 3.

3. IDENTIFY THE MALFUNCTIONING SYSTEM WITH SYMPTOM DIAGNOSIS

Use Symptom diagnosis from the symptom inspection result in step 2 and then identify where to start performing the diagnosis based on possible causes and symptoms.

>> GO TO 4.

4. PERFORM THE COMPONENT DIAGNOSIS OF THE OF THE APPLICABLE SYSTEM

Perform the diagnosis with Component diagnosis of the applicable system.

>> GO TO 5.

5. REPAIR OR REPLACE THE MALFUNCTIONING PARTS

Repair or replace the specified malfunctioning parts.

>> GO TO 6.

6. FINAL CHECK

Check that malfunctions are not reproduced when obtaining the malfunction information from the customer, referring to the symptom inspection result in step 2.

Are the malfunctions corrected? YES >> Inspection End.

NO >> GO TO 3.

Basic inspection

Basic inspection

...

Additional service when removing battery negative terminal

Additional service when removing battery negative terminal

Description

When the battery negative terminal is disconnected, the initialization is

necessary for normal operation of

power window system.

CAUTION:

The following specified operations can not b ...

Other materials:

P1805 Brake switch

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P1805

BRAKE SW/CIRCUIT

(Brake switch circuit)

Stop lamp signal is not sent to ECM for extremely

long time while the vehicle is drivi ...

Dtc/circuit diagnosis

Power supply and ground circuit

Audio unit

AUDIO UNIT : Diagnosis Procedure

Regarding wiring diagram information, refer to av-88, "wiring diagram".

1.Check fuse

Check that the following fuses are not blown.

Are the fuses blown?

Yes >> replace the blown fuse after repairing ...

ID registration cannot be completed

Diagnosis Procedure

NOTE:

The Signal Tech II Tool (J-50190) can be used to perform the following

functions. Refer to the Signal Tech II

User Guide for additional information.

Activate and display TPMS transmitter IDs

Display tire pressure reported by the TPMS transmitter

Read TPMS DTCs

...