Nissan Sentra Service Manual: Main line between ipdm-e and dlc circuit

Diagnosis procedure

1.Check connector

- Turn the ignition switch off.

- Disconnect the battery cable from the negative terminal.

- Check the following terminals and connectors for damage, bend and loose connection (connector side and harness side).

- Harness connector E4

- Harness connector m2

Is the inspection result normal? Yes >> go to 2.

No >> repair the terminal and connector.

2.Check harness continuity (open circuit)

- Disconnect the following harness connectors.

- Ipdm e/r

- Harness connectors E4 and M2

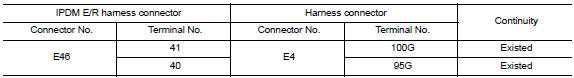

- Check the continuity between the ipdm e/r harness connector and the harness connector.

Is the inspection result normal? Yes >> go to 3.

No >> repair the main line between the ipdm e/r and the harness connector e4.

3.Check harness continuity (open circuit)

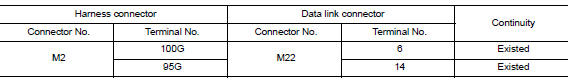

Check the continuity between the harness connector and the data link connector.

Is the inspection result normal? Yes (present error)>>check can system type decision again.

Yes (past error)>>error was detected in the main line between the ipdm e/r and the data link connector.

No >> repair the main line between the harness connector m2 and the data link connector.

Can system (type 5)

Can system (type 5)

Dtc/circuit diagnosis ...

Main line between dlc and hvac circuit

Main line between dlc and hvac circuit

Diagnosis procedure

1.Check harness continuity (open circuit)

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Disconnect the following harness connector ...

Other materials:

Combination meter

Reference Value

VALUES ON THE DIAGNOSIS TOOL

NOTE:

The following table includes information (items) inapplicable to this

vehicle. For information (items) applicable

to this vehicle, refer to CONSULT display items.

Note:

Some items are not available according to vehicle specificat ...

System

Meter system

Meter system : system diagram

Meter system : system description

COMBINATION METER

The combination meter receives signals from switches, sensors and modules to

control the following functions:

Speedometer/tachometer

Warning lamps

Indicator lamps

Meter illumination c ...

Low tire pressure warning lamp

Symptom Table

Low tire pressure warning lamp symptom chart

Note:

If tire pressure sensor wake-up operation is not completed for two or more

tire pressure sensors, the applicable

low tire pressure warning lamp blinking patterns are displayed continuously.

(Example: blinks once/off/bl ...