Nissan Sentra Service Manual: Removal and installation

REAR WHEEL HUB

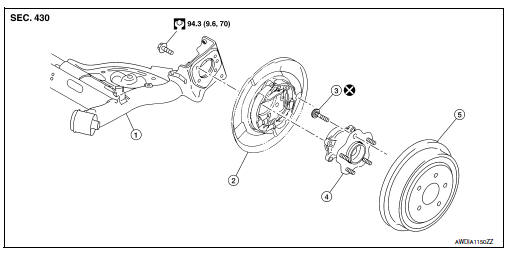

Exploded View - Drum brake

DRUM BRAKE

- Rear suspension beam

- Brake assembly

- Wheel stud

- Wheel hub assembly (Bearing-integrated type)

- Brake drum

Removal and Installation - Drum brake

REMOVAL

- Remove the wheel and tire using power tool. Refer to WT-47, "Removal and Installation".

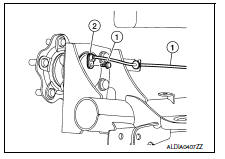

- Remove the rear wheel sensor bolt (1) and the rear wheel sensor (2). Refer to BRC-107, "REAR WHEEL SENSOR : Removal and Installation".

- Remove rear brake drum. Refer to BR-42, "Removal and Installation".

CAUTION:

Do not depress brake pedal while rear brake drum is removed.

- Remove the hub bolts and wheel hub assembly.

CAUTION:

Do not remove parking brake assembly. Protect it from falling.

INSTALLATION

Installation is in the reverse order of removal.

- Check that the wheel hub assembly operates smoothly

- Perform inspection after installation. Refer to RAX-8, "Inspection".

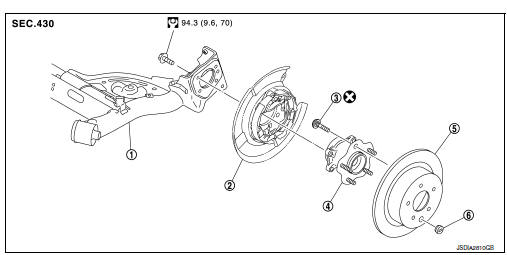

Exploded View - Disc brake

DISK BRAKE

- Rear suspension beam

- Parking brake assembly

- Wheel stud

- Wheel hub assembly (Bearing-integrated type)

- Disc rotor

- Plug

Removal and Installation - Disc brake

REMOVAL

- Remove the wheel and tire using power tool. Refer to WT-47, "Removal and Installation".

- Remove the rear wheel sensor bolt (1) and the rear wheel sensor (2). Refer to BRC-107, "REAR WHEEL SENSOR : Removal and Installation".

- Remove the rear brake caliper assembly. Refer to BR-47, "BRAKE CALIPER ASSEMBLY : Removal and Installation".

CAUTION:

Do not depress brake pedal while rear brake assembly is removed.

- Remove the hub bolts and wheel hub assembly.

CAUTION:

Do not remove parking brake assembly. Protect it from falling.

INSTALLATION

Installation is in the reverse order of removal.

- Align the matching marks that have been made during removal when reusing the disc rotor.

- Check that the wheel hub assembly operates smoothly

- Perform inspection after installation. Refer to RAX-8, "Inspection".

Inspection

INSPECTION AFTER REMOVAL

Check the wheel hub assembly for wear, cracks, and damage. Replace if necessary.

INSPECTION AFTER INSTALLATION

- Check wheel sensor harness for proper connection. Refer to BRC-107, "REAR WHEEL SENSOR : Exploded View".

- Adjust parking brake operation (stroke). Refer to PB-4, "Inspection and Adjustment".

- Check wheel alignment. Refer to RSU-6, "Inspection".

Periodic maintenance

Periodic maintenance

REAR WHEEL HUB

Inspection

COMPONENT PART

Check the mounting conditions (looseness, back lash) of each component and

component conditions (wear,

damage) are normal.

WHEEL HUB ASSEMBLY (BEARING-I ...

Service data and specifications (SDS)

Service data and specifications (SDS)

Wheel Bearing

...

Other materials:

Diagnosis system (bcm)

Common item

Common item : consult function (bcm - common item)

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BCM.

Direct Diagnostic Mode

Description

ECU identification

The BCM part number is displayed.

Self Diagnostic Result

...

U1010 control unit (can)

Description

Initial diagnosis of combination meter.

Dtc logic

Dtc detection logic

Dtc

Display contents of consult

Detection condition

Possible malfunction

U1010

CONTROL UNIT (CAN)

[U1010]

When detecting error during the initial diagnosis of

the can controlle ...

Unit disassembly and assembly

Moonroof unit assembly

Exploded view

Drain assembly

Glass lid

Weatherstrip

Moonroof rail assembly

Drain hose front (RH)

Moonroof motor assembly

Drain hose front (LH)

Side bracket (LH)

Drain hose rear (LH)

Sunshade stopper (LH)

Sunshade

Sunshade stopper (RH)

Drain hos ...