Nissan Sentra Service Manual: Control cable

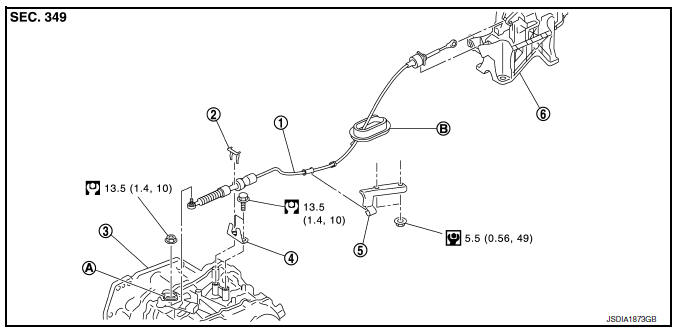

Exploded View

- Control cable

- Lock plate

- Transaxle assembly

- Bracket A

- Bracket B

- CVT shift selector assembly

- Manual lever

- Grommet

Removal and Installation

INSTALLATION

CAUTION:

Always apply the parking brake before performing removal and installation.

- Apply the parking brake.

CAUTION:

Make sure the vehicle cannot move with the parking brake applied.

- Remove the center console assembly. Refer to IP-17, "Removal and Installation".

- Move the shift selector to “P” position

- Remove the control cable from the shift selector assembly with the following procedure.

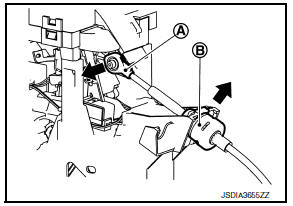

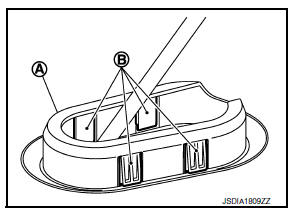

- Disconnect the tip (A) of control cable from the shift selector assembly.

- Remove socket (B) from shift selector assembly.

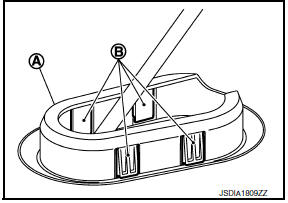

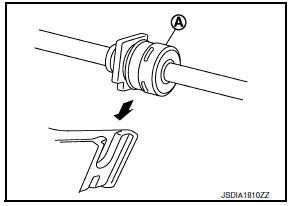

- Disengage the pawls (B) of the grommet (A), and pull downwards to remove.

- Remove the battery. Refer to PG-50, "Removal and Installation (Battery)".

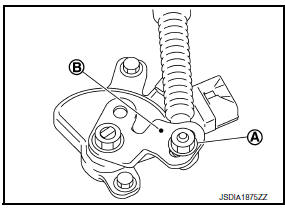

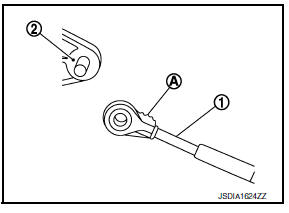

- Remove the control cable installation nut (A) from the manual lever (B).

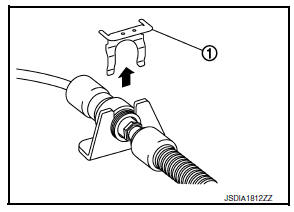

- Remove the lock plate (1).

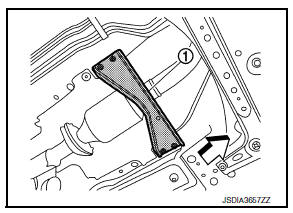

- Remove the tunnel stay (1).

: Front

: Front

- Remove the exhaust front tube and sub muffler from the exhaust system. Refer to EX-5, "Removal and Installation".

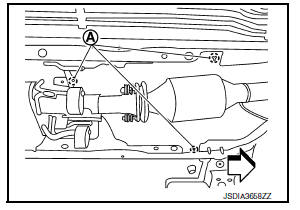

- Remove the heat plate fixtures (A).

: Front

: Front

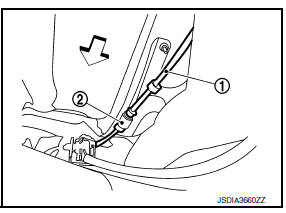

- Remove the control cable (1) from the bracket (2).

: Front

: Front

- Remove the control cable from the vehicle.

INSTALLATION

Installation is in the reverse order of removal.

- From below the vehicle, press the grommet (A) into place until the pawls (B) make a click sound.

CAUTION:

- Place the grommet on the floor, then fasten it in place from below the vehicle.

- Check that pulling down on the grommet does not disconnect it.

- Pay attention to the following when connecting the control cable to the shift selector.

- When connecting the control cable (1) to the shift selector assembly (2), face the grooved surface of the rib (A) up and insert the control cable until it stops.

- Install the socket (A) onto the shift selector.

CAUTION:

- Place the socket onto the shift selector, then fasten it in place from above.

- Check that the pulling on the socket does not disconnect it.

Inspection and Adjustment

INSPECTION AND ADJUSTMENT

Check the CVT position. If a malfunction is found, adjust the CVT position. Refer to TM-150, "Inspection" (Inspection) or TM-150, "Adjustment" (Adjustment).

CVT Shift selector

CVT Shift selector

Exploded View

Shift selector knob

Lock pin

Knob cover

Position indication panel

Detent switch

Shift lock unit

Park position switch

Shift selector assembly

Shift selector harne ...

Key interlock cable

Key interlock cable

Exploded View

Shift selector assembly

Clip

Key interlock cable

Clip

Key cylinder

Removal and Installation

REMOVAL

CAUTION:

Always apply the parking brake before performing remov ...

Other materials:

Engine assembly M/T

M/T : Exploded View

Washer

Upper torque rod (RH)

Engine mounting insulator (RH)

Rear torque rod bracket

Rear torque rod

Engine mounting bracket (LH)

Engine mounting frame support (LH)

Engine mounting insulator (LH)

CAUTION:

Check that the stud bolt (*2) is tight at the spe ...

Power outlet

Center Console

Console Box (if so equipped)

The power outlets are for powering electrical

accessories such as cellular telephones. They

are rated at 12 volt, 120W (10A) maximum.

The power outlets are powered only when the

ignition switch is in the ACC or ON position.

CAUTION

The ...

Anti-pinch system does not operate normally (driver side)

Diagnosis Procedure

1.CHECK POWER WINDOW AUTO OPERATION

Check AUTO operation when anti-pinch function does not operate.

Refer to PWC-67, "Diagnosis Procedure".

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 2.

2.REPLACE POWER WINDOW MAIN SWITCH

...