Nissan Sentra Service Manual: Brake booster

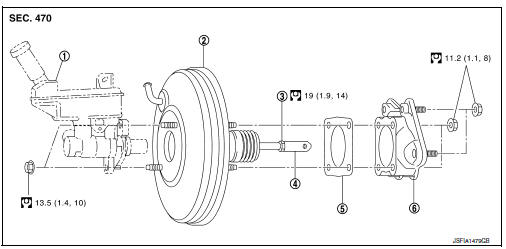

Exploded View

- Master cylinder assembly

- Brake booster

- Lock nut

- Clevis

- Gasket

- Spacer

Removal and installation

REMOVAL

- Remove cowl top and cowl top extension. Refer to EXT-26, "Removal and Installation".

- Remove air duct and air cleaner case. Refer to EM-25, "Removal and Installation".

- Remove brake master cylinder assembly. Refer to BR-32, "Removal and Installation".

- Remove vacuum hose from brake booster. Refer to BR-36, "Removal and Installation".

- Remove the instrument lower panel LH. Refer to IP-21, "Removal and Installation".

- Remove snap pin (1) and clevis pin (2). Refer to BR-22, "Exploded View".

- Remove nuts on brake booster and brake pedal assembly.

CAUTION:

Secure the brake booster to avoid damage to components.

- Remove brake booster and spacer.

CAUTION:

Do not deform or bend brake pipes.

NOTE:

If removing brake booster is difficult, remove clevis from brake booster.

- Remove vacuum pipe from brake booster.

- Remove spacer from brake booster.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Be careful not to damage brake booster stud bolt threads. If brake booster is tilted during installation, the dash panel may damage the threads.

- Do not deform or bend the brake tubes when installing the brake booster.

- Always use a gasket between the brake booster and the spacer.

- Do not reuse the clevis pin.

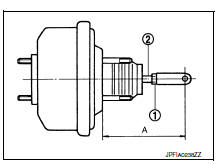

- Loosen the lock nut (1) and adjust the input rod (2) to the specified length (A). Tighten the lock nut to the specified torque.

Length (A) : Refer to BR-55, "Brake Booster".

- Perform the air bleeding. Refer to BR-17, "Bleeding Brake System".

- Check each item of brake pedal. Adjust it if the measurement value is not the standard. Refer to BR-11, "Inspection".

Brake master cylinder

Brake master cylinder

Exploded View

Reservoir cap

Oil strainer

Reservoir tank

Cylinder body

Pin

O-ring

Grommet

Apply brake fluid

PBC (Poly Butyl Cuprysil)

grease or

silicone-based grease

Remo ...

Vacuum lines

Vacuum lines

Exploded View

Clamp

Vacuum hose (built-in check valve)

Vacuum piping

Vacuum hose

To intake manifold side

Paint mark

Stamp indicating engine direction

To brake booster

Remo ...

Other materials:

Diagnosis system (bcm) (with intelligent key system)

Common item

Common item : consult function (bcm - common item)

Application item

Consult performs the following functions via can communication with bcm.

Direct diagnostic mode

Description

ECU identification

The BCM part number is displayed.

Self diagnostic result

...

Symptom diagnosis

Engine does not start when intelligent key is inside of vehicle

Description

Engine does not start when push-button ignition switch is pressed while

carrying intelligent key.

Note:

Check that vehicle is under the condition shown in “conditions of

vehicle” before starting diagnos ...

Transmitter

Exploded View

Transmitter (tire pressure sensor)

O-ring

Valve stem nut

Valve core

Valve cap

Valve stem assembly

Parts that are replaced as a set

when the tire is replaced.

Removal and Installation

REMOVAL

Remove road wheel and tire assembly using power tool.

Remove val ...