Nissan Sentra Service Manual: Vacuum lines

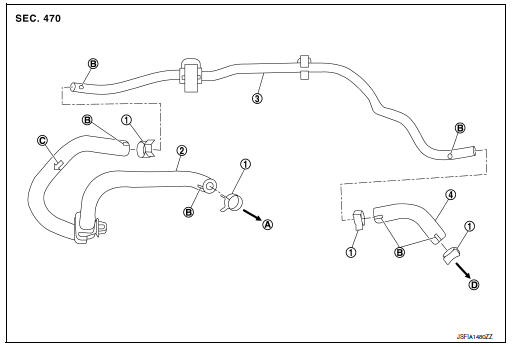

Exploded View

- Clamp

- Vacuum hose (built-in check valve)

- Vacuum piping

- Vacuum hose

- To intake manifold side

- Paint mark

- Stamp indicating engine direction

- To brake booster

Removal and Installation

REMOVAL

- Remove air duct and air cleaner case. Refer to EM-25, "Removal and Installation".

- Remove the vacuum hoses and vacuum piping.

INSPECTION AFTER REMOVAL

Visual Inspection

Check for correct installation, damage and deterioration of the vacuum hoses and pipe.

Valve Air-tightness Check

- Connect a suitable tool at each end of the vacuum hose with built-in check valve to inspect the check valve operation.

Vacuum applied at booster end : Refer to BR-54, "Check Valve".

Vacuum applied at intake manifold end : Refer to BR-54, "Check Valve".

- Replace the vacuum hose with built-in check valve if out of specification.

INSTALLATION

Installation is in the reverse order of removal.

- When installing vacuum hose, insert it until its tip reaches the back-end of length (A) or further as shown.

CAUTION:

Do not use lubricating oil during assembly

Length (A) : 24 mm (0.95 in) or more

- Face the paint mark of vacuum hose (build-in check valve) (intake manifold side) to vehicle right side to assemble.

- Face the paint mark of vacuum hose (build-in check valve) (brake booster side) to vehicle front side to assemble.

- Face the paint mark of vacuum piping (intake manifold side) to vehicle front side to assemble.

- Face the paint mark of vacuum piping (brake booster side) to downward to assemble.

- Face the paint mark of vacuum hose (intake manifold side) to downward to assemble.

- Face the paint mark of vacuum hose (brake booster side) to vehicle front side to assemble.

- For clamp mounting direction (the orientation of pawl), refer to BR-36, "Exploded View".

Brake booster

Brake booster

Exploded View

Master cylinder assembly

Brake booster

Lock nut

Clevis

Gasket

Spacer

Removal and installation

REMOVAL

Remove cowl top and cowl top extension. Refer to EXT-26, ...

Front disc brake

Front disc brake

BRAKE PAD

BRAKE PAD : Exploded View

Cylinder body

Inner shim cover

Inner shim

Inner pad (with pad wear sensor)

Pad retainer

Torque member

Outer pad

Outer shim

Outer shim cover ...

Other materials:

Environmental factors influence the rate of corrosion

Moisture

Accumulation of sand, dirt and water on the vehicle

body underside can accelerate corrosion.

Wet floor coverings will not dry completely inside

the vehicle and should be removed for drying to

avoid floor panel corrosion.

Relative humidity

Corrosion will be accelerated in areas of h ...

Dtc/circuit diagnosis

U1000 can comm circuit

DTC Logic

DTC DETECTION LOGIC

CONSULT Display

DTC Detection Condition

Possible Cause

CAN COMM CIRCUIT

[U1000]

AV control unit is not transmitting or receiving

CAN communication signal for 2 seconds or

more.

CAN communication system.

...

The ambient temperature display is incorrect

Description

The displayed outside air temperature is higher than the actual

temperature.

The displayed outside air temperature is lower than the actual

temperature.

Outside air temperature is not indicated.

Diagnosis procedure

1.Check ambient sensor signal circuit

Check the ambie ...