Nissan Sentra Service Manual: Brake pedal position switch

Component Function Check

1.CHECK BRAKE PEDAL POSITION SWITCH FUNCTION

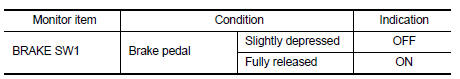

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select đ▓đéĐÜENGINEđ▓đéĐť using CONSULT.

- Select đ▓đéĐÜBRAKE SW1đ▓đéĐť in đ▓đéĐÜDATA MONITORđ▓đéĐť mode.

- Check đ▓đéĐÜBRAKE SW1đ▓đéĐť indication under the following conditions.

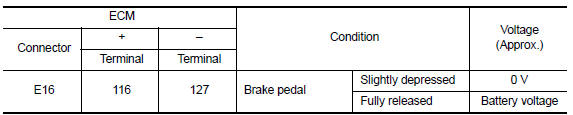

Without CONSULT

Without CONSULT

- Turn ignition switch ON.

- Check the voltage between ECM harness connector terminals under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-446, "Diagnosis Procedure".

Diagnosis Procedure

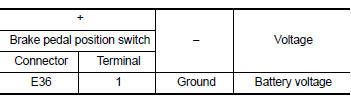

1.CHECK BRAKE PEDAL POSITION SWITCH POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect brake pedal position switch harness connector.

- Turn ignition switch ON.

- Check the voltage between brake pedal position switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

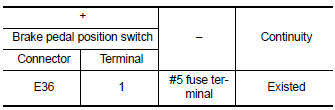

2.CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT

- Pull out #5 fuse.

- Check that the fuse is not fusing.

- Check the continuity between stop lamp switch harness connector and fuse terminal.

- Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> Check power supply circuit for 12V battery power supply.

NO >> Repair or replace error-detected parts.

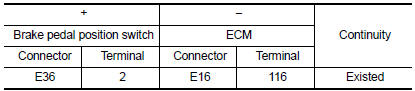

3.CHECK BRAKE PEDAL POSITION SWITCH INPUT SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between brake pedal position switch harness connector and ECM harness connector.

- Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK BRAKE PEDAL POSITION SWITCH

Check brake pedal position switch. Refer to EC-447, "Component Inspection (Brake Pedal Position Switch)" Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Replace brake pedal position switch. Refer to BR-22, "Exploded View".

Component Inspection (Brake Pedal Position Switch)

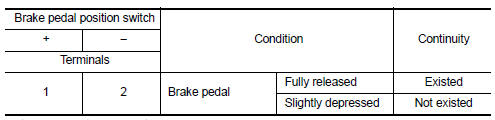

1.CHECK BRAKE PEDAL POSITION SWITCH-I

- Turn ignition switch OFF.

- Disconnect brake pedal position switch harness connector.

- Check the continuity between brake pedal position switch terminals under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 2.

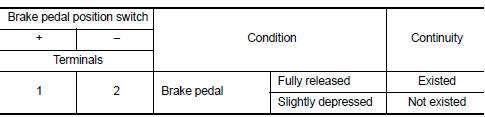

2.CHECK BRAKE PEDAL POSITION SWITCH-II

- Adjust brake pedal position switch installation. Refer to BR-15, "Adjustment".

- Check the continuity between brake pedal position switch terminals under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace brake pedal position switch. Refer to BR-22, "Exploded View".

Sensor power supply 2 circuit

Sensor power supply 2 circuit

Description

ECM supplies a voltage of 5.0 V to some of the sensors systematically divided

into 2 groups, respectively.

Accordingly, when a short circuit develops in a sensor power source, a

ma ...

ASCD Indicator

ASCD Indicator

Component Function Check

1.CHECK ASCD INDICATOR FUNCTION

Check ASCD indicator under the following conditions.

ASCD INDICATOR

CONDITION

SPECIFICATION

CRUISE LAMP

Ig ...

Other materials:

Diagnosis system (ipdm e/r) (with intelligent key system)

Diagnosis description

Auto active test

Description

In auto active test, the IPDM E/R sends a drive signal to the following

systems to check their operation.

Front wiper (lo, hi)

Parking lamp

License plate lamp

Tail lamp

Front fog lamp (if equipped)

Headlamp (LO, HI)

A/C compress ...

Application Download

Once connected, the NissanConnectÔäó App will

search your phone to determine which compatible

applications are currently installed. The user

will then choose which apps they want to bring

into their vehicle from the list of apps within the

ÔÇťManage My AppsÔÇŁ section of the NissanConnect

Ôäó ...

Rear door

Door assembly

Door assembly : removal and installation

Caution:

Use two people when removing or installing the rear door assembly

due to its heavy weight.

When removing and installing rear door assembly, support rear door

with a suitable tool.

Removal

Remove rear door assembly h ...