Nissan Sentra Service Manual: Structure and operation

TRANSAXLE

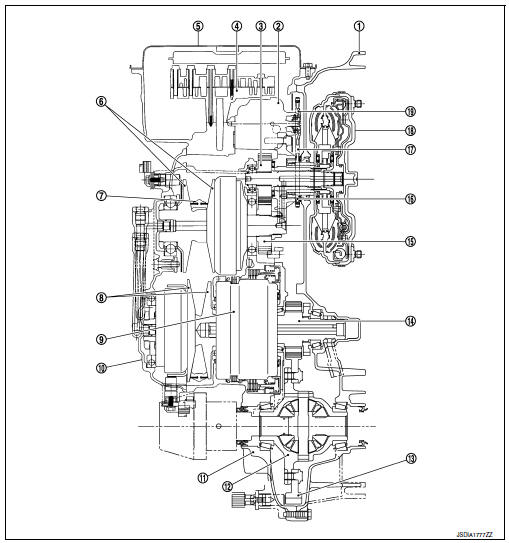

TRANSAXLE : Cross-Sectional View

- Converter housing

- Oil pump

- Counter drive gear

- Control valve

- Oil pan

- Primary pulley

- Steel belt

- Secondary pulley

- Planetary gear (auxiliary gearbox)

- Side cover

- Transaxle case

- Differential case

- Final gear

- Reduction gear

- Counter driven gear

- Drive sprocket

- Oil pump chain

- Torque converter

- Driven sprocket

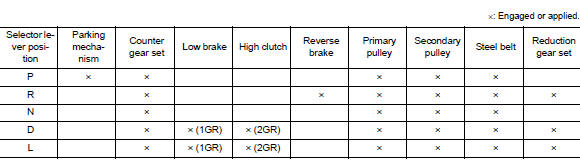

TRANSAXLE : Operation Status

TRANSAXLE : Transaxle Mechanism

BELT & PULLEY

Mechanism

It is composed of a pair of pulleys (the groove width is changed freely in the axial direction) and the steel belt (the steel plates are placed continuously and the belt is guided with the multilayer steel rings on both sides).

The groove width changes according to wrapping radius of steel belt and pulley from low status to overdrive status continuously with non-step. It is controlled with the oil pressures of primary pulley and secondary pulley.

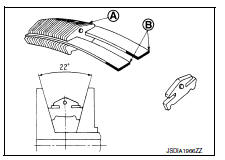

Steel belt

It is composed of multiple steel plates and two steel rings stacked to a several number. The feature of this steel belt transmits power with compression of the steel plate in contrast with transmission of power in pulling with a rubber belt. Friction force is required with the pulley slope to transmit power from the steel plate. The force is generated with the following mechanism: Oil pressure applies to the secondary pulley to nip the plate. ⇒The plate is pushed and extended outward. ⇒The steel ring shows withstands.

⇒Pulling force is generated on the steel ring. ⇒The plate of the primary pulley is nipped between the pulley. ⇒Friction force is generated between the steel belt and the pulley.

Therefore, responsibilities are divided by the steel plate that transmits the power with compression and the steel ring that maintains necessary friction force. In this way, the tension of the steel ring is distributed on the entire surface and stress variation is limited, resulting in good durability.

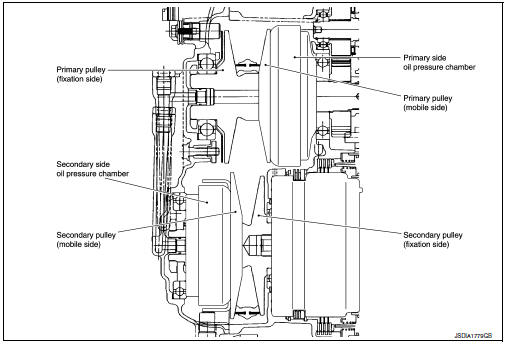

Pulley

The primary pulley (input shaft side) and the secondary pulley (output shaft side) have the shaft with slope (fixed cone surface), movable sheave (movable cone surface that can move in the axial direction) and oil pressure chamber at the back of the movable sheave.

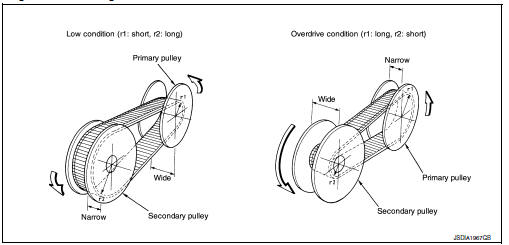

Pulley gear shifting operation

- Pulley gear shifting operation

The movable sheave slides on the shaft to change the groove width of the pulley. Input signals of engine load (accelerator pedal opening), engine revolution and gear ratio (vehicle speed) change the operation pressures of the primary pulley and the secondary pulley, and controls the pulley groove width. Along with change of the pulley groove width, the belt contact radius is changed. This allows continuous and stepless gear shifting from low to overdrive. “The contact radius ratio of each pulley in contact with the belt x auxiliary gearbox gear ratio” is the gear ratio.

AUXILIARY GEARBOX MECHANISM

1st, 2nd and reverse gears are changed with the planetary gear mechanism.

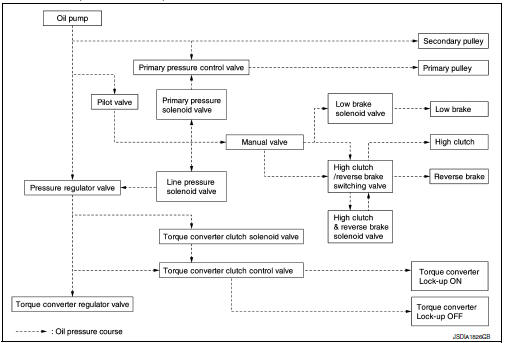

TRANSAXLE : Oil Pressure System

Oil pressure required for operation of the transaxle transmission mechanism is generated by oil pump, oil pressure control valve, solenoid valve, etc.

TRANSAXLE : Component Description

| Part name | Function |

| Torque converter | It is composed of the cover converter, turbine assembly, stator, pump impeller assembly, etc. It increases the engine torque and transmits the power to the transaxle. |

| Oil pump | Through the oil pump drive chain, it uses the vane oil pump driven by the engine. It generates necessary oil pressure to circulate fluid and to operate the clutch and brake. |

| Counter gear set | The power from the torque converter is transmitted to the primary pulley through the counter drive gear and the counter driven gear. |

| Belt & pulley (Continuously variable transmission) | It is composed of the primary pulley, secondary pulley, steel belt, etc. and the mechanism performs shifting, changes the gear ratio and transmits the power with oil pressure from the control valve. |

| Auxiliary gearbox (stepped transmission) | It is composed of the planetary gear, multi-disc clutch, multi-disc brake, etc. and the mechanism performs shifting (1-2 gear shifting and reverse) with oil pressure from the control valve. |

| Reduction gear set | Conveys power from the transmission mechanism to the reduction gear and the final gear. |

| Parking mechanism | When the shift lever is changed to P position, the mechanism fixes the parking gear (integrated with the reduction gear) and the fixes the output shaft |

| Control valve | Controls oil pressure from the oil pump to the pressure suitable for the line pressure control system, shift control system, lock-up control system and lubrication system. |

| Pressure regulator valve | Adjusts the discharge pressure from the oil pump to the optimum pressure (line pressure) corresponding to the driving condition. |

| Torque converter regulator valve | Adjusts the feed pressure to the torque converter to the optimum pressure corresponding to the driving condition. |

| Pilot valve | Adjusts line pressure and produces a constant pressure (pilot pressure) necessary for activating each solenoid valve. |

| Manual valve | Distributes the clutch and brake operation pressures (pilot pressure) corresponding to each shift position. |

| High clutch/reverse brake switching valve | Switches the circuit for the high clutch and the reverse brake. |

| Torque converter clutch control valve | It is operated with the torque converter clutch solenoid valve and it adjusts the tightening pressure and non-tightening pressure of the torque converter clutch piston of the torque converter. |

| Primary pressure control valve | It is operated with the primary pressure solenoid valve and adjusts the feed pressure to the primary pulley. |

| Primary pressure solenoid valve | TM-79, "CVT CONTROL SYSTEM : Primary Pressure Solenoid Valve" |

| Low brake solenoid valve | TM-79, "CVT CONTROL SYSTEM : Low Brake Solenoid Valve" |

| High clutch & reverse brake solenoid valve | TM-80, "CVT CONTROL SYSTEM : High Clutch & Reverse Brake Solenoid Valve" |

| Torque converter clutch solenoid valve | TM-80, "CVT CONTROL SYSTEM : Torque Converter Clutch Solenoid Valve" |

| Line pressure solenoid valve | TM-81, "CVT CONTROL SYSTEM : Line Pressure Solenoid Valve" |

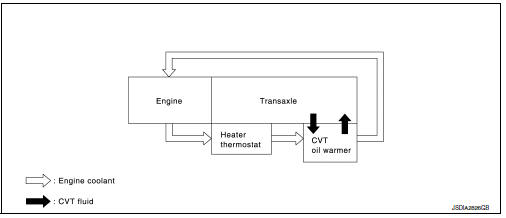

FLUID COOLER & FLUID WARMER SYSTEM

FLUID COOLER & FLUID WARMER SYSTEM :System Description

CVT FLUID COOLER SCHEMATIC

COMPONENT DESCRIPTION

CVT Oil Warmer

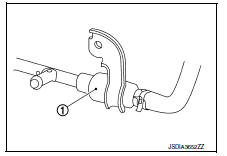

- The CVT oil warmer is installed on the front part of transaxle assembly.

- When engine is started while engine and CVT are cold, engine

coolant temperature rises more quickly than CVT fluid temperature.

CVT oil warmer is provided with two circuits for CVT and engine coolant respectively so that warmed engine coolant warms CVT quickly. This helps shorten CVT warming up time, improving fuel economy.

- A cooling effect is obtained when CVT fluid temperature is high.

Heater Thermostat

- The heater thermostat

is installed to front

is installed to front

part of transaxle assembly. - The heater thermostat open and close with set temperature.

SHIFT LOCK SYSTEM

SHIFT LOCK SYSTEM : System Description

- The shift lock is the mechanism provided to prevent quick start of a vehicle by incorrect operation of a drive when the selector lever is in “P” position.

- Selector lever can be shifted from the “P” position to another position when the following conditions are satisfied.

- Ignition switch is ON.

- Stop lamp switch is ON (brake pedal is depressed)

- Press the selector button.

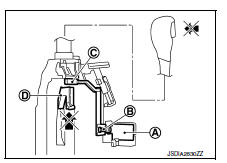

SHIFT LOCK OPERATION AT P POSITION

When brake pedal is not depressed (no selector operation allowed)

When the brake pedal is not depressed with the ignition switch ON,

the shift lock solenoid

is OFF (not

is OFF (not

energized) and the solenoid rod

is extended

is extended

with spring.

The connecting lock lever

is located at the position

is located at the position

shown in the

figure when the solenoid rod is extended. It prevents the movement

of the detent rod

. The selector lever cannot be shifted from the “P”

position for this reason.

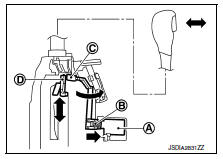

When brake pedal is depressed (selector lever operation allowed)

The shift lock solenoid

is turned ON (energized)

is turned ON (energized)

when the brake

pedal is depressed with the ignition switch ON. The solenoid rod

is compressed with the electromagnetic force. The connecting lock

lever

rotates when the solenoid rod is compressed. Therefore, the

detent rod can be moved

. The selector lever can be

. The selector lever can be

shifted to

other positions for this reason.

P POSITION HOLD MECHANISM (IGNITION SWITCH LOCK)

The shift lock solenoid  is not energized when the ignition switch is

is not energized when the ignition switch is

in any position other than ON. The shift mechanism is locked and “P”

position is held. The operation cannot be performed from “P” position

if the brake pedal is depressed with the ignition switch ON when the

operation system of shift lock solenoid is malfunctioning. However,

the lock lever

is forcibly rotated and the shift lock is released when

the shift lock release button

is pressed from

is pressed from

above. The selector

operation from “P” position can be performed.

: Detent rod

: Detent rod

CAUTION:

Use the shift lock release button only when the selector lever cannot be operated even if the brake pedal is depressed with the ignition switch ON.

KEY LOCK SYSTEM

KEY LOCK SYSTEM : System Description

KEY LOCK MECHANISM

The key is not set to LOCK when the selector lever is not selected to P position. This prevents the key from being removed from the key cylinder.

Key lock status

The slider  in the key cylinder

in the key cylinder  is moved to the left side of the figure

is moved to the left side of the figure

when the selector lever is in any position other than “P” position.

The rotator  that

that

rotates together with the key cannot be rotated

for this reason. The key cannot be removed from the key cylinder

because it cannot be turned to LOCK

.

.

Key unlock status

The slider  in the key cylinder

in the key cylinder  is moved to the right side of the

is moved to the right side of the

figure when the selector lever is in “P” position and the finger is

removed from the selector button. The rotator

can be

can be

rotated for

this reason. The key  can be removed from the key cylinder

can be removed from the key cylinder

because it can be turned to LOCK  .

.

System description

System description

Component parts

CVT CONTROL SYSTEM

CVT CONTROL SYSTEM : Component Parts Location

No.

Component

Function

1

ECM

Mainly transmits the following signal to TCM via CAN

...

System

System

CVT CONTROL SYSTEM

CVT CONTROL SYSTEM : System Diagram

CVT CONTROL SYSTEM : System Description

DESCRIPTION

CVT detects the vehicle driving status from switches, sensors and

signals, a ...

Other materials:

Heated seats (if so equipped)

The front seats are warmed by built-in heaters.

Start the engine.

Push the LO or HI position of the switch, as

desired. The indicator light in the switch will

illuminate.

The heater is controlled by a thermostat,

automatically turning the heater on and off.

The indicator light ...

Symptom diagnosis

Push-button ignition switch does not operate

Description

Check that vehicle is under the condition shown in “Conditions of vehicle”

before starting diagnosis, and check

each symptom.

Note:

The engine start function, door lock function, power distribution system,

and nats-ivis/nvis ...

M&a branch line circuit

Diagnosis procedure

1.Check connector

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the combination meter for damage,

bend and loose connection

(unit side and connector side).

Is the inspection result nor ...