Nissan Sentra Service Manual: Starter motor drive control

STARTER MOTOR DRIVE CONTROL : System Description

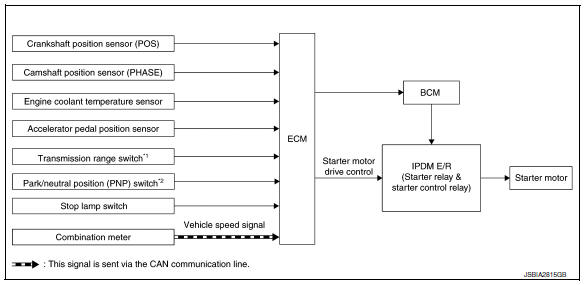

SYSTEN DIAGRAM

*1: CVT models

*2: M/T models

INPUT/OUTPUT SIGNAL CHART

| Sensor | Input signal to ECM | ECM function | Actuator | |

| Crankshaft position sensor (POS) |

|

Starter motor drive control |

|

|

| Camshaft position sensor (PHASE) | ||||

| Engine coolant temperature sensor | Engine coolant temperature | |||

| Accelerator pedal position sensor | Accelerator pedal position | |||

| Transmission range switch (CVT) | Gear position | |||

| Park/ Neutral position switch (M/T) | Gear position | |||

| Stop lamp switch | Brake pedal position | |||

| Combination meter | CAN communication | Vehicle speed signal | ||

SYSTEM DESCRIPTION

When rapid deceleration occurs during engine runs or idle speed decreases due to heavy load conditions, ECM detects a decrease in idle speed and restarts the engine to secure reliability in handleability by transmitting a cranking request signal to IPDM E/R for activating the starter motor under the following conditions:

- Selector lever: Other than P and N (CVT models)

- Shifter lever: Other than neutral position (M/T models)

- Idle switch: ON (Accelerator pedal not depressed)

- Brake switch: ON (Brake pedal depressed)

ECM transmits a control signal to IPDM E/R via BCM by CAN communication.

IPDM E/R detects an operating state of the starter motor relay and the starter motor control relay and transmits a feed back signal to ECM via CAN Communication.

Cooling fan control

Cooling fan control

SYSTEM DIAGRAM

SYSTEM DESCRIPTION

ECM controls cooling fan speed corresponding to vehicle speed, engine coolant

temperature, refrigerant pressure,

air conditioner ON signal. Then control syst ...

Evaporative emission system

Evaporative emission system

EVAPORATIVE EMISSION SYSTEM : System Description

SYSTEM DIAGRAM

INPUT/OUTPUT SIGNAL CHART

Sensor

Input signal to ECM

ECM function

Actuator

Crankshaft position sensor (P ...

Other materials:

P0131 A/F Sensor 1

DTC Logic

DTC DETECTION LOGIC

To judge the malfunction, the diagnosis checks that the A/F signal computed

by ECM from the A/F sensor 1

signal is not inordinately low.

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P01 ...

Can communication circuit

Diagnosis procedure

1.Connector inspection

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Disconnect all the unit connectors on can communication system.

Check terminals and connectors for damage, bend and loose connection.

Is the inspection resu ...

NISSAN Intelligent Key® battery discharge

If the battery of the NISSAN Intelligent Key® is

discharged, or environmental conditions interfere

with the Intelligent Key operation, start the engine

according to the following procedure:

Place the shift lever in the P (Park) position.

Firmly apply the foot brake.

Touch the ignitio ...