Nissan Sentra Service Manual: Roof side molding

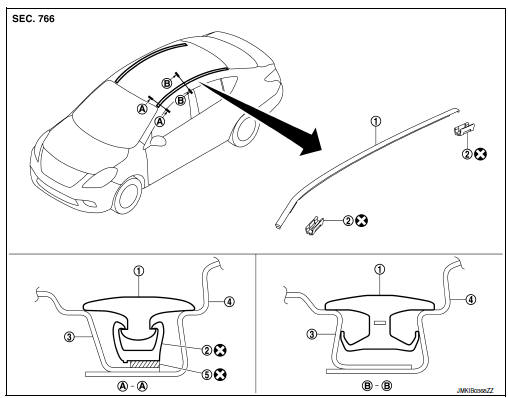

Exploded view

- Roof side molding

- Roof side molding clip

- Roof panel

- Body side outer panel

- Adhesive tape

Removal and installation

REMOVAL

ROOF SIDE MOLDING

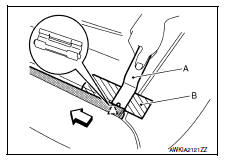

- Release roof side molding rear side clip, using a suitable tool (A).

Clip

Clip

Front

Front

CAUTION:

Apply protective tape (B) on body to protect the painted surface from damage.

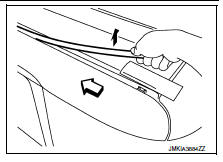

- Pull up roof side molding from rear end to front end.

Front

Front

CAUTION:

Use care when pulling the roof side molding to avoid damaging.

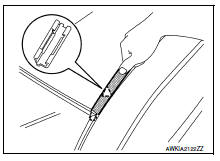

- Release windshield molding and clip at the front end of roof side molding, then remove while pulling toward vehicle rear.

: Clip

: Clip

REMOVAL OF ROOF SIDE MOLDING CLIPS

Heat adhesive tape using a heat gun and peel roof side molding clips (body side) using a suitable tool.

CAUTION:

Be careful not to damage the body.

INSTALLATION

- Clean tape removed surface with isopropyl alcohol or equivalent.

- Use two-part epoxy adhesive.

Adhesive : 3M-weld DP–100 or equivalent

- Apply adhesive evenly to clip tape surface.

Thickness : Approximately 0.5 mm (0.020 in)

- Position applied parts to the proper location, and then sufficiently press-fit until the adhesive protrudes to tape side.

Press-fit limit : 19.6 N× 2 seconds

- Tape roof side molding clips after press fit and temporarily hold it for specified time based on the following.

5 to 10В°C (41 to 50В°F) : 1 hour or more

11 to 23В°C (52 to 73В°F) : 30 minutes or more

24В°C or more (75В°F or more) : 15 minutes or more

CAUTION:

- Use double-sided tape after hardening for roof side molding clips.

- Securely insert molding rear end cap onto roof rear end cutout (installation standard).

- When installing roof side molding of windshield glass portion, check that body side molding fastener is securely inserted and then press in.

- Do not wash the vehicle within 24 hours so as to keep adhesive dry.

Under cover

Under cover

Front under cover

Front under cover : removal and installation

REMOVAL

Remove front side of front fender protector (LH/RH). Refer to EXT-28,

"FENDER PROTECTOR : Removal

and Installatio ...

Drip molding

Drip molding

Exploded view

Drip molding

Clip

Removal and installation

REMOVAL

Release drip molding clips, then remove drip molding.

INSTALLATION

Installation is in the reverse order of removal. ...

Other materials:

Brakes

If the brakes do not operate properly, have the

brakes checked by a NISSAN dealer.

Self-adjusting brakes

Your vehicle is equipped with self-adjusting

brakes.

The front (and rear– if so equipped) disc-type

brakes self-adjust every time the brake pedal is

applied. The rear drum-type brakes ...

ABS Warning lamp

Component Function Check

1.CHECK ABS WARNING LAMP FUNCTION

Check that ABS warning lamp in combination meter turns ON for

approximately 2 seconds after ignition switch

is turned ON.

Is the inspection result normal?

YES >> Inspection End.

NO >> Proceed to diagnosis procedure. ...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The supplemental restraint system such as “air bag” and “seat belt pre-tensioner”,

used along

with a front seat belt, helps to reduce the risk or severity of injur ...