Nissan Sentra Service Manual: P1800 Intake manifold tuning valve

DTC Logic

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition | Possible cause |

| P1800 | VIAS S/V-1 (Variable intake air system control solenoid valve-1) | An excessively low or high voltage signal is sent to ECM through the intake manifold tuning valve. |

|

DTC CONFIRMATION PROCEDURE

1.CONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm battery voltage is more than 11 V at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Start engine and warm it up to the normal operating temperature. [more than 60В°C (140В°F)]

- Let it idle for at least 10 seconds. (engine speed: less than 1,000 rpm)

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-408, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK INTAKE MANIFOLD TUNING VALVE MOTOR POWER SUPPLY

- Turn ignition switch ON.

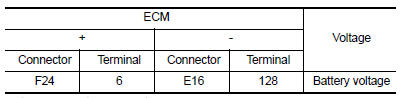

- Check the voltage between ECM harness connector.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK INTAKE MANIFOLD TUNING VALVE MOTOR POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

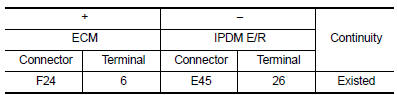

- Disconnect ECM harness connector.

- Disconnect IPDM E/R harness connector.

- Check the continuity between ECM harness connector and IPDM E/R harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

3.CHECK INTAKE MANIFOLD TUNING VALVE MOTOR OUTPUT SIGNAL CIRCUIT

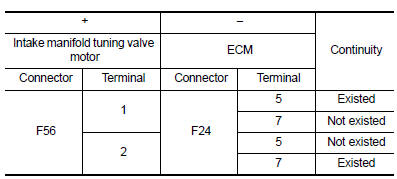

- Disconnect intake manifold tuning valve motor harness connector

- Check the continuity between intake manifold tuning valve motor harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK INTAKE MANIFOLD TUNING VALVE MOTOR

Check the intake manifold tuning valve motor. Refer to EC-409, "Component Inspection (Intake Manifold Tuning Valve)".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Replace intake manifold assembly. Refer to EM-27, "Removal and Installation".

Component Inspection (Intake Manifold Tuning Valve)

1.CHECK INTAKE MANIFOLD TUNING VALVE MOTOR

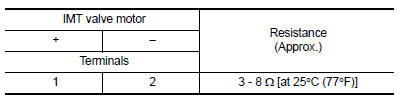

- Turn ignition switch OFF.

- Disconnect intake manifold tuning valve motor harness connector.

- Check the resistance between intake manifold tuning valve motor terminals as per the following.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace intake manifold. Refer to EM-27, "Removal and Installation".

P1715 Input speed sensor

P1715 Input speed sensor

Description

ECM receives input speed sensor signal from TCM through CAN communication

line. ECM uses this signal for

engine control.

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P1715 is disp ...

P1805 Brake switch

P1805 Brake switch

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P1805

BRAKE SW/CIRCUIT

(Brake switch c ...

Other materials:

P1588 G Sensor

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P1588

G Sensor

(Gravity Sensor Circuit)

When the following diagnosis conditions are

satisfied and the detection conditi ...

How to erase permanent DTC

Description

OUTLINE

When a DTC is stored in ECM

When a DTC is stored in ECM and MIL is ON, a permanent DTC is erased with MIL

shutoff if the same malfunction

is not detected after performing the driving pattern for MIL shutoff three times

in a raw.

*1: When the same malfunction is detec ...

Blower motor

Exploded View

Heating and cooling unit assembly

Blower motor

Front

Removal and Installation

Remove the glove box assembly. Refer to IP-22, "Removal and

Installation".

Disconnect the harness connector from the blower motor.

Remove the blower motor screws.

Remove ...