Nissan Sentra Service Manual: P0335 CKP Sensor (POS)

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0340 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643. Refer to EC- 353, "DTC Logic".

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition | Possible cause |

| P0335 | CKP SEN/CIRCUIT (Crankshaft position sensor “A” circuit) |

|

|

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10.5 V with ignition switch ON.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Start engine and let it idle for at least 5 seconds.

If engine does not start, crank engine for at least 2 seconds.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-277, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

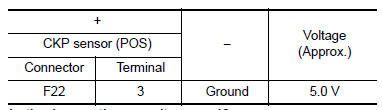

1.CHECK CRANKSHAFT POSITION (CKP) SENSOR (POS) POWER SUPPLY

- Disconnect crankshaft position (CKP) sensor (POS) harness connector.

- Turn ignition switch ON.

- Check the voltage between CKP sensor (POS) harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

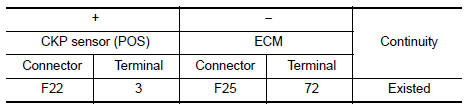

2.CHECK CKP SENSOR (POS) POWER SUPPLY CIRCUIT

- Turn ignition switch OFF

- Disconnect ECM harness connector.

- Check the continuity between CKP sensor (POS) harness connector and ECM harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

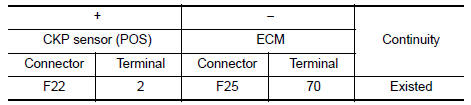

3.CHECK CKP SENSOR (POS) GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector

- Check the continuity between CKP sensor (POS) harness connector and ECM harness connector.

- Also check harness for short to power

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

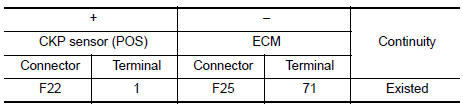

4.CHECK CKP SENSOR (POS) INPUT SIGNAL CIRCUIT

- Check the continuity between CKP sensor (POS) harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

5.CHECK CRANKSHAFT POSITION SENSOR (POS)

Check the crankshaft position sensor (POS). Refer to EC-279, "Component Inspection [CKP Sensor (POS)]".

Is the inspection result normal? YES >> GO TO 6.

NO >> Replace crankshaft position sensor (POS). Refer to EM-33, "Exploded View".

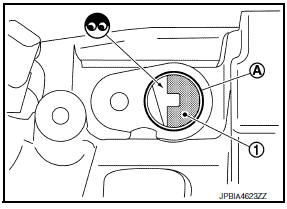

6.CHECK GEAR TOOTH

- Remove crankshaft position sensor (POS). Refer to EM-33, "Exploded View".

- Look into the mounting hole

of

of

the crankshaft position sensor (POS) to check that there is no missing gear tooth in the signal plate 1.

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Replace the signal plate. Refer to EM-90, "Exploded View" (M/T) or EM-92, "Exploded View" (CVT).

Component Inspection [CKP Sensor (POS)]

1.CHECK CRANKSHAFT POSITION SENSOR (POS)-1

- Turn ignition switch OFF.

- Loosen the fixing bolt of the sensor.

- Disconnect crankshaft position sensor (POS) harness connector.

- Remove the sensor.

- Visually check the sensor for chipping.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace crankshaft position sensor (POS). Refer to EM- 33, "Exploded View".

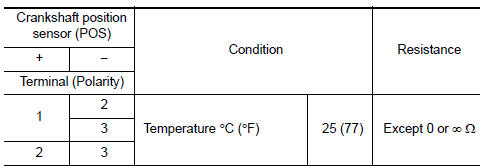

2.CHECK CRANKSHAFT POSITION SENSOR (POS)-2

Check the resistance between crankshaft position sensor (POS) terminals as per the following.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace crankshaft position sensor (POS). Refer to EM-33, "Exploded View".

P0327, P0328 KS

P0327, P0328 KS

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0327

KNOCK SEN/CIRC-B1

(Knock sensor ...

P0340 CMP Sensor (PHASE)

P0340 CMP Sensor (PHASE)

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0340

CMP SEN/CIRC-B1

(Camshaft positi ...

Other materials:

Diagnosis system (BCM)

Common item

Common item : consult function (bcm - common item)

Application item

Consult performs the following functions via can communication with bcm.

Direct diagnostic mode

Description

Ecu identification

The bcm part number is displayed.

Self Diagnostic Result

...

Instrument panel

Headlight/fog light (if so equipped)/turn

signal switch

Steering wheel switch for trip

computer, audio control and

Bluetooth® Hands-Free Phone System

(if so equipped)

Driver’s supplemental air bag/Horn

Meters and gauges

Cruise control main/set switches

(if so equipped)

...

Rear drum brake

Brake Burnishing

CAUTION:

Burnish contact surfaces between brake drum and brake lining

according to the following procedure

after refinishing or replacing brake drum, or if a soft pedal occurs at very

low mileage.

Be careful of vehicle speed because the brake does not operate

firml ...