Nissan Sentra Service Manual: Overdrive control switch

Component Function Check

1.CHECK SPORT INDICATOR LAMP FUNCTION

Check OD OFF indicator lamp turns ON for approx. 2 seconds when ignition switch turns ON.

Is the inspection result normal? YES >> GO TO 2.

NO >> Go to TM-239, "Diagnosis Procedure".

2.CHECK SPORT MODE SWITCH FUNCTION

- Shift the selector lever to “D” position.

- Check that OD OFF indicator lamp turns ON/OFF when overdrive control switch is operated.

Is the inspection result normal? YES >> INSPECTION END

NO >> Go to TM-236, "Diagnosis Procedure".

Diagnosis Procedure

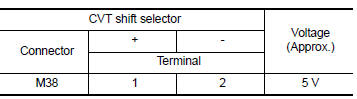

1.CHECK OVERDRIVE CONTROL SWITCH CIRCUIT

- Turn ignition switch OFF

- Disconnect CVT shift selector connector.

- Turn ignition switch ON.

- Check voltage between CVT shift selector harness connector terminals.

Is the inspection

Is the inspection

result normal?

YES >> GO TO 2.

NO >> GO TO 4.

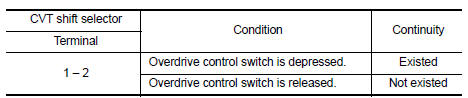

2.CHECK CVT SHIFT SELECTOR ASSEMBLY

Check continuity between CVT shift selector connector terminals.

Is the inspection

Is the inspection

result normal?

YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> GO TO 3.

3.CHECK OVERDRIVE CONTROL SWITCH

Check overdrive control switch. Refer to TM-237, "Component Inspection (Overdrive Control Switch)".

Is the inspection result normal? YES >> Replace CVT shift selector assembly. Refer to TM-253, "Removal and Installation".

NO >> Repair or replace malfunctioning parts.

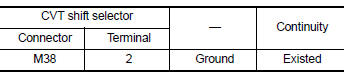

4.CHECK GROUND CIRCUIT

Check continuity between CVT shift selector harness connector terminal and ground.

Is the inspection

Is the inspection

result normal?

YES >> GO TO 5.

NO >> Repair or replace malfunctioning parts.

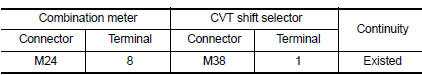

5.CHECK CIRCUIT BETWEEN COMBINATION METER AND CVT SHIFT SELECTOR (PART 1)

- Turn ignition switch OFF

- Disconnect combination meter connector.

- Check continuity between combination meter harness connector terminal and CVT shift selector harness connector terminal.

Is the inspection

Is the inspection

result normal?

YES >> GO TO 6.

NO >> Repair or replace malfunctioning parts.

6.CHECK CIRCUIT BETWEEN COMBINATION METER AND CVT SHIFT SELECTOR (PART 2)

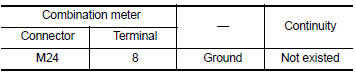

Check continuity between combination meter harness connector terminal and ground.

Is the inspection

Is the inspection

result normal?

YES >> GO TO 7.

NO >> Repair or replace malfunctioning parts.

7.CHECK COMBINATION METER INPUT SIGNAL

- Connect all of disconnected connectors.

- Turn ignition switch ON.

- Select “Data Monitor” in “METER/M&A”.

- Select “O/D OFF SW”.

- Check that “O/D OFF SW” turns ON/OFF when overdrive control switch is operated. Refer to MWI-20, "Reference Value".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Replace combination meter. Refer to MWI-77, "Removal and Installation".

Component Inspection (Overdrive Control Switch)

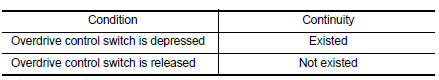

1.Check overdrive control switch

Check continuity between wires of selector lever knob 1.

Is the inspection

Is the inspection

result normal?

YES >> INSPECTION END

NO >> Replace selector lever knob. Refer to TM-253, "Removal and Installation".

Main power supply and ground circuit

Main power supply and ground circuit

Diagnosis Procedure

1.CHECK TCM POWER CIRCUIT (PART 1)

Turn ignition switch OFF.

Disconnect TCM connector.

Check voltage between TCM harness connector terminals and ground.

Is the insp ...

Od off indicator lamp

Od off indicator lamp

Component Function Check

1.CHECK OD OFF INDICATOR LAMP FUNCTION

Check OD OFF indicator lamp turns ON for approx. 2 seconds when ignition

switch turns ON.

Is the inspection result normal?

YES ...

Other materials:

1110, C1170 ABS Actuator and electric unit (control unit)

DTC Logic

DTC DETECTION LOGIC

DTC

Display item

Malfunction detected condition

Possible cause

C1110

CONTROLLER FAILURE

When there is an internal malfunction in the ABS actuator

and electric unit (control unit).

ABS actuator and electric unit

(contr ...

AM radio reception

AM signals, because of their low frequency, can

bend around objects and skip along the ground.

In addition, the signals can be bounced off the

ionosphere and bent back to earth. Because of

these characteristics, AM signals are also subject

to interference as they travel from transmitter

to r ...

The oil pressure warning lamp does not turn off

Description

The oil pressure warning lamp remains illuminated while the engine is running

(normal oil pressure).

Diagnosis procedure

1.Check combination meter input signal

Start the engine and select METER/M&A on CONSULT.

Observe oil w/l data monitor and the operation of the oil pres ...