Nissan Sentra Owners Manual: Manual transmission (if so equipped)

WARNING

|

CAUTION

- Do not rest your foot on the clutch pedal while driving. This may cause clutch damage.

- Fully depress the clutch pedal before shifting to help prevent transmission damage.

- Stop your vehicle completely before shifting into R (Reverse).

- When the vehicle is stopped with the engine running (for example, at a stop light), shift to N (Neutral) and release the clutch pedal with the foot brake applied.

- Do not shift to the “N”(Neutral) position while driving. Doing so may result in an accident due to loss of engine braking.

Shifting

To change gears or when upshifting or downshifting, depress the clutch pedal fully, shift into the appropriate gear, then release the clutch slowly and smoothly.

To ensure smooth gear changes, fully depress the clutch pedal before operating the shift lever. If the clutch pedal is not fully depressed before the transmission is shifted, a gear noise may be heard. Transmission damage may occur.

Start the vehicle in 1st gear and shift to 2nd, 3rd, 4th and 5th up to 6th gear in sequence according to vehicle speed.

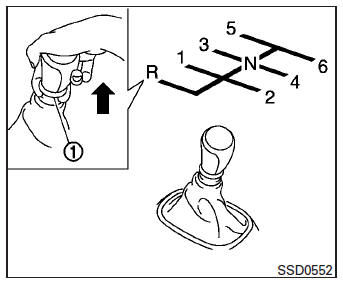

To back up, lift up on the shift lever ring 1 and then move it to the R (Reverse) position after stopping the vehicle completely.

The shift lever ring 1 returns to its original position when the shift lever is moved to the N (Neutral) position.

If it is difficult to move the shift lever into R (Reverse) or 1 (1st), shift into N (Neutral), then release the clutch pedal. Depress the clutch pedal again and shift into R (Reverse) or 1 (1st).

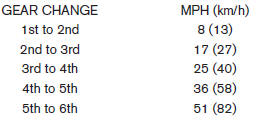

Suggested up-shift speeds

The following are suggested vehicle speeds for shifting into a higher gear. These suggestions relate to fuel economy and vehicle performance.

Actual upshift speeds will vary according to road conditions, the weather and individual driving habits.

Suggested maximum speed in each gear

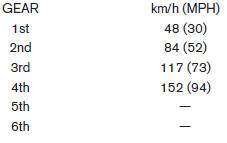

Downshift to a lower gear if the engine is not running smoothly, or if you need to accelerate.

Do not exceed the maximum suggested speed (shown below) in any gear. For level road driving, use the highest gear suggested for that speed.

Always observe posted speed limits, and drive according to the road conditions, which will ensure safe operation. Do not over-rev the engine when shifting to a lower gear as it may cause engine damage or loss of vehicle control.

MRA8DE engine models (6 M/T)

Continuously Variable Transmission (CVT) (if so equipped)

Continuously Variable Transmission (CVT) (if so equipped)

WARNING

Do not depress the accelerator pedal

while shifting from P (Park) or N (Neutral)

to R (Reverse), D (Drive) or L (Low).

Always depress the brake pedal until

shifting ...

Parking brake

Parking brake

WARNING

Be sure the parking brake is fully released

before driving. Failure to do so

can cause brake failure and lead to an

accident.

Do not release the parking brake from

...

Other materials:

FM/AM/SAT radio with compact disc (CD) player (Type A) (if so equipped)

For all operation precautions, see “Audio operation

precautions” in this section.

Audio main operation

VOL (volume) knob / PWR (power) button:

Place the ignition switch in the ACC or ON

position and press the VOL (volume) knob /PWR

(power) button while the system is off to call up

the mod ...

Symptom diagnosis

Noise, vibration and harshness (NVH) troubleshooting

NVH troubleshooting chart

Locate the area where noise occurs.

Confirm the type of noise.

Specify the operating condition of engine.

Check specified noise source.

If necessary, repair or replace these parts.

Closely relate ...

Removal and installation

A/C ASSEMBLY SWITCH

Removal and Installation

Removal

Remove the cvt shift selector finisher (cvt: re0f11a). Refer to tm-253,

"removal and installation".

Remove the MT shift selector finisher (6MT: RS6F94R). Refer to TM-22,

"Exploded View".

Remove the front air con ...