Nissan Sentra Service Manual: Main line between ipdm-e and dlc circuit

Diagnosis procedure

1.Check connector

- Turn the ignition switch OFF.

- Disconnect the battery cable from the negative terminal.

- Check the following terminals and connectors for damage, bend and loose connection (connector side and harness side).

- Harness connector E4

- Harness connector M2

Is the inspection result normal? Yes >> go to 2.

No >> repair the terminal and connector.

2.Check harness continuity (open circuit)

- Disconnect the following harness connectors.

- Ipdm e/r

- Harness connectors e4 and m2

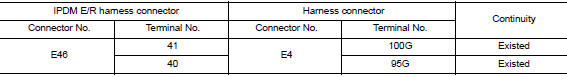

- Check the continuity between the ipdm e/r harness connector and the harness connector.

Is the inspection result normal? Yes >> go to 3.

No >> repair the main line between the ipdm e/r and the harness connector e4.

3.Check harness continuity (open circuit)

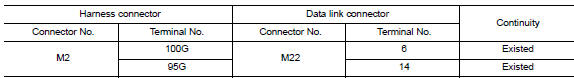

Check the continuity between the harness connector and the data link connector.

Is the inspection result normal? Yes (present error)>>check can system type decision again.

Yes (past error)>>error was detected in the main line between the ipdm e/r and the data link connector.

No >> repair the main line between the harness connector m2 and the data link connector.

Can system (type 1)

Can system (type 1)

Dtc/circuit diagnosis ...

Ecm branch line circuit

Ecm branch line circuit

Diagnosis procedure

1.Check connector

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the ecm for damage, bend and ...

Other materials:

ECU diagnosis information

Diagnosis sensor unit

DTC Index

DIAGNOSTIC CODE CHART

NOTE:

Follow the procedures in numerical order when repairing malfunctioning

parts. Confirm whether malfunction is

eliminated using air bag warning lamp or CONSULT each time repair is finished.

If malfunction is still

observed, proceed ...

Preparation

Special Service Tools

NOTE:

The actual shapes of Kent-Moore tools may differ from those of special

service tools illustrated here.

Commercial Service Tools

...

Precaution

Precaution for supplemental restraint system (srs) "air bag" and "seat belt

pre-tensioner"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT

PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injur ...