Nissan Sentra Service Manual: How to select piston and bearing

Description

| Selection points | Selection parts | Selection items | Selection methods |

| Between cylinder block and crankshaft | Main bearing | Main bearing grade (bearing thickness) | Determined by match of cylinder block bearing housing grade (inner diameter of housing) and crankshaft journal grade (outer diameter of journal) |

| Between crankshaft and connecting rod | Connecting rod bearing | Connecting rod bearing grade (bearing thickness) | Combining service grades for connecting rod big end diameter and crankshaft pin outer diameter determine connecting rod bearing selection. |

| Between cylinder block and piston | Piston and piston pin assembly (piston is available together with piston pin as an assembly.) | Piston grade (piston outer diameter) | Piston grade = cylinder bore grade (inner diameter of bore) |

- The identification grade stamped on each part is the grade for the

dimension measured in new condition.

This grade cannot apply to reused parts

- For reused or repaired parts, measure the dimension accurately. Determine the grade by comparing the measurement with the values of each selection table.

- For details of the measurement method of each part, the reuse standards and the selection method of the selective fitting parts, refer to the text.

Piston

When new cylinder block is used

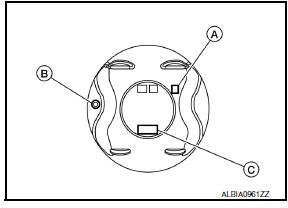

- Check the cylinder bore grade on rear (LH) side of cylinder block (L), and select piston of the same grade.

- Correction stamp

- Standard stamp

- Cylinder No. 1 bore grade

- Cylinder No. 2 bore grade

- Cylinder No. 3 bore grade

- Cylinder No. 4 bore grade

- No. 1 main bearing housing grade

- No. 2 main bearing housing grade

- No. 3 main bearing housing grade

- No. 4 main bearing housing grade

- No. 5 main bearing housing grade

- If there is a correction stamp mark on the cylinder block, use it as a correct reference.

When cylinder block is reused

- Measure the cylinder bore inner diameter. Refer to EM-123, "Cylinder Block".

- Determine the bore grade by comparing the measurement with the values under the cylinder bore inner diameter of the “Piston Selection Table”.

- Select piston of the same grade.

- Piston grade number

- Front mark

- Identification code

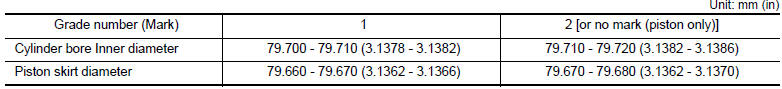

Piston selection table

NOTE:

Piston is available together with piston pin as an assembly.

Connecting Rod Bearing

When new connecting rod and crankshaft are used

- Apply connecting rod big end diameter grade stamped on connecting rod side face to the row in the “Connecting Rod Bearing Selection Table”.

- Oil hole

- Engine type

- Cylinder number

- Big end diameter grade

- Front mark

- Apply crankshaft pin journal diameter grade stamped on crankshaft front side to the column in the “Connecting Rod Bearing Selection Table”.

No. 1 pin journal diameter grade

No. 2 pin journal diameter grade

No. 3 pin journal diameter grade

No. 4 pin journal diameter grade

No. 1 main journal diameter grade

No. 2 main journal diameter grade

No. 3 main journal diameter grade

No. 4 main journal diameter grade

No. 5 main journal diameter grade

- Read the symbol at the cross point of selected row and column in the “Connecting Rod Bearing Selection Table”.

- Apply the symbol obtained to the “Connecting Rod Bearing Grade Table” to select connecting rod bearing.

When connecting rod and crankshaft are reused

- Measure the dimensions of the connecting rod big end diameter and

crankshaft pin journal diameter individually.

Refer to em-103, "inspection".

- Apply the measured dimension to the “Connecting Rod Bearing Selection Table”.

- Read the symbol at the cross point of selected row and column in the “connecting rod bearing selection table”.

- Apply the symbol obtained to the “Connecting Rod Bearing Grade Table” to select connecting rod bearing.

Connecting rod bearing selection table

Connecting rod bearing grade table

Connecting rod bearing grade table : Refer to EM-127, "Connecting Rod Bearing".

Undersize bearings usage guide

- When the specified connecting rod bearing oil clearance is not obtained with standard size connecting rod bearings, use undersize (us) bearings

- When using undersize (us) bearing, measure the connecting rod bearing inner diameter with bearing installed, and grind the crankshaft pin so that the connecting rod bearing oil clearance satisfies the standard.

Caution:

In grinding crankshaft pin to use undersize bearings, keep the fillet r [1.5 - 1.7 Mm (0.059 - 0.067 In)] (a).

Bearing undersize table : refer to em-127, "connecting rod bearing".

Main Bearing

When new cylinder block and crankshaft are used

- “Main Bearing Selection Table” rows correspond to main bearing housing grade on rear (LH) side of cylinder block (L).

- Correction stamp

- Standard stamp

- Cylinder No. 1 bore grade

- Cylinder No. 2 bore grade

- Cylinder No. 3 bore grade

- Cylinder No. 4 bore grade

- No. 1 main bearing housing grade

- No. 2 main bearing housing grade

- No. 3 main bearing housing grade

- No. 4 main bearing housing grade

- No. 5 main bearing housing grade

- If there is a correction stamp mark on cylinder block, use it as a correct reference.

- Apply main journal diameter grade stamped on crankshaft front side to column in the “Main Bearing Selection Table”.

- No. 1 pin journal diameter grade

- No. 2 pin journal diameter grade

- No. 3 pin journal diameter grade

- No. 4 pin journal diameter grade

- No. 1 main journal diameter grade

- No. 2 main journal diameter grade

- No. 3 main journal diameter grade

- No. 4 main journal diameter grade

- No. 5 main journal diameter grade

- Read the symbol at the cross point of selected row and column in the “Main Bearing Selection Table”.

CAUTION:

There are two main bearing selection tables. One is for No. 1, 4, and 5 journals and the other is for No. 2 and 3 journals. Make certain to use the appropriate table. This is due to differences in the specified clearances.

- Apply the symbol obtained to the “Main Bearing Grade Table” to select main bearing.

NOTE:

Service part is available as a set of both upper and lower.

When cylinder block and crankshaft are reused

- Measure the dimensions of the cylinder block main bearing housing inner diameter and crankshaft main journal diameter individually. Refer to EM-103, "Inspection".

- Apply the measured dimension to the “Main Bearing Selection Table”.

- Read the symbol at the cross point of selected row and column in the “Main Bearing Selection Table”.

CAUTION:

There are two main bearing selection tables. One is for No. 1, 4, and 5 journals and the other is for No. 2 and 3 journals. Make certain to use the appropriate table. This is due to differences in the specified clearances.

- Apply the symbol obtained to the “Main Bearing Grade Table” to select main bearing.

NOTE:

Service part is available as a set of both upper and lower.

Main bearing selection table(No. 1, 4, AND 5 JOURNAL)

Main bearing selection table (no. 2 And 3 journal)

Main bearing grade table(ALL JOURNALS)

Main bearing grade table (All journals) : Refer to EM-127, "Main Bearing".

Undersize bearing usage guide

- When the specified main bearing oil clearance is not obtained with standard size main bearings, use undersize (US) bearing.

- When using undersize (US) bearing, measure the main bearing inner diameter with bearing installed, and grind main journal so that the main bearing oil clearance satisfies the standard.

CAUTION:

In grinding crankshaft main journal to use undersize bearings, keep the fillet R [1.5 - 1.7 mm (0.059 - 0.067 in)] (A).

Bearing undersize table: Refer to EM-127, "Main Bearing".

Cylinder block

Cylinder block

Exploded View

Cylinder block

Block heater (for Canada)

Top ring

Second ring

Oil ring

Piston

Piston pin

Snap ring

Connecting rod

Connecting rod bearing (upper)

Connecting r ...

Service data and specifications

(sds)

Service data and specifications

(sds)

General Specification

Drive Belt

Spark Plug

*:Always check with the Parts Department for the latest parts information.

Exhaust Manifold

Camshaft

VALVE LIFTER

VALVE CLE ...

Other materials:

A-bag branch line circuit

Diagnosis procedure

Warning:

Always observe the following items for preventing accidental

activation.

Before servicing, turn ignition switch off, disconnect battery

negative terminal, and wait 3 minutes

or more. (To discharge backup capacitor.)

Never use unspecified tester or other ...

Clutch master cylinder

Exploded View

Reservoir hose

Reservoir tank

Clutch master cylinder

Removal and Installation

REMOVAL

CAUTION:

Keep painted surface on the body or other parts free of clutch

fluid. If it spills, wipe up immediately

and wash the affected area with water.

Do not disassemble c ...

P0300, P0301, P0302, P0303, P0304 Misfire

DTC Logic

DTC DETECTION LOGIC

When a misfire occurs, engine speed will fluctuate. If the engine speed

fluctuates enough to cause the crankshaft

position (CKP) sensor (POS) signal to vary, ECM can determine that a misfire is

occurring.

Sensor

Input signal to ECM

ECM function

...