Nissan Sentra Service Manual: Cylinder block

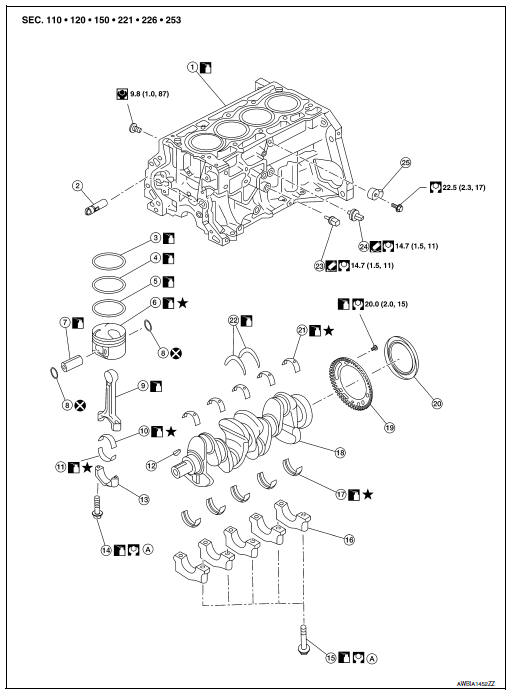

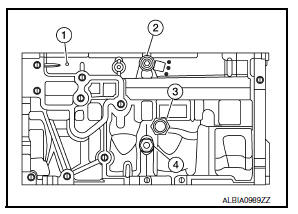

Exploded View

- Cylinder block

- Block heater (for Canada)

- Top ring

- Second ring

- Oil ring

- Piston

- Piston pin

- Snap ring

- Connecting rod

- Connecting rod bearing (upper)

- Connecting rod bearing (lower)

- Crankshaft key

- Connecting rod cap

- Connecting rod cap bolt

- Main bearing cap bolt

- Main bearing cap

- Main bearing (lower)

- Crankshaft

- Signal plate

- Rear oil seal

- Main bearing (upper)

- Thrust bearing

- Oil temperature sensor

- Oil pressure sensor

- Knock sensor

- Refer to INSTALLATION

Disassembly and Assembly

- Remove engine and transaxle assembly from the vehicle. Refer to EM-82, "M/T : Exploded View" (M/T) or EM-86, "CVT : Exploded View" (CVT).

- Remove the clutch cover and clutch. Refer to CL-17, "Exploded View".

- Remove the flywheel or drive plate. Refer to EM-90, "Exploded View" (M/T) or EM-92, "Exploded View" (CVT).

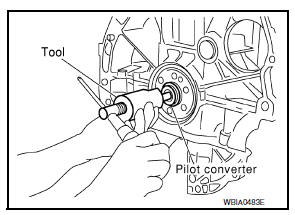

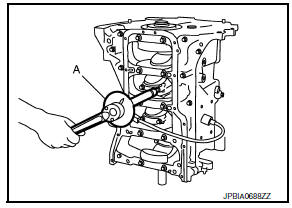

- Remove pilot converter using Tool.

Tool Number : ST16610001 (J-23907)

- Remove the rear oil seal. Refer to EM-70, "REAR OIL SEAL : Removal and Installation".

CAUTION:

Do not damage the crankshaft or cylinder block when removing the rear oil seal.

- Install engine to engine stand with the following procedure:

- Remove flywheel or drive plate. Refer to EM-90, "Exploded View" (M/T models) or EM-92, "Exploded View" (CVT models).

- Remove pilot converter. Refer to EM-92, "Exploded View" (CVT models).

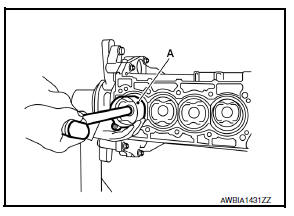

- Lift the engine with a hoist to install it onto widely use engine stand.

CAUTION:

- Use the engine stand that has a load capacity [approximately 135 kg (298 lb) or more] large enough for supporting the engine weight.

- If the load capacity of stand is not adequate, remove the following parts beforehand to reduce the potential risk of overturning stand.

- Intake manifold: Refer to EM-27, "Exploded View".

- Rocker cover: Refer to EM-46, "Exploded View".

NOTE:

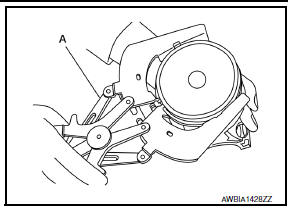

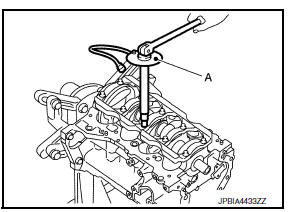

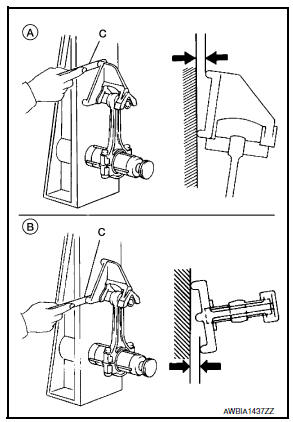

The illustration shows an example of widely used engine stand (A) that can support mating surface of transaxle with flywheel (M/T models) or drive plate (CVT models) removed.

CAUTION:

Before removing the hanging chains, check the engine stand is stable and there is no risk of overturning.

- Drain engine oil. Refer to LU-8, "Draining".

CAUTION:

Be sure to clean drain plug and install with new drain plug washer.

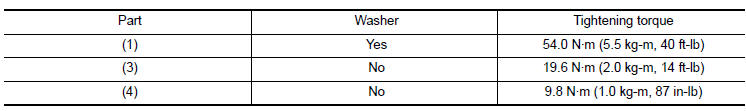

- Drain fluids and lubricants by removing drain plugs (1, 3 and 4) the cylinder block.

- Tightening torque : Refer to EM-95, "Disassembly and Assembly".

Use Genuine Silicone RTV Sealant, or equivalent. Refer to GI-21, "Recommended Chemical Products and Sealants".

- Remove the engine harness.

- Remove the oil pan (upper). Refer to EM-33, "Exploded View".

- Remove the water pump. Refer to CO-19, "Exploded View".

- Remove thermostat housing. Refer to CO-21, "Exploded View".

- Remove the water outlet. Refer to CO-24, "Exploded View".

- Remove the cylinder head. Refer to EM-72, "Exploded View".

- Remove knock sensor (2).

CAUTION:

Carefully handle sensor avoiding shocks.

- Remove the oil pressure (3) and oil temp sensor (4).

CAUTION:

Do not reuse O-ring.

- Remove piston and connecting rod assembly with the following procedure:

- Before removing piston and connecting rod assembly, check the connecting rod side clearance. Refer to EM-103, "Inspection".

- Position crankshaft pin corresponding to connecting rod to be removed onto the bottom dead center.

- Remove connecting rod cap. Number connecting rod caps so they can be assembled in the same position and direction.

- Using a hammer handle or similar tool, push piston and connecting rod assembly out to the cylinder head side.

CAUTION:

- Do not damage matching surface with connecting rod cap.

- Do not damage the cylinder wall and crankshaft pin, resulting from an interference of the connecting rod big end.

- Remove connecting rod bearings.

CAUTION:

When removing them, note the installation position. Keep them in the correct order.

- Remove piston rings from piston.

- Before removing piston rings, check the piston ring side clearance. Refer to EM-103, "Inspection".

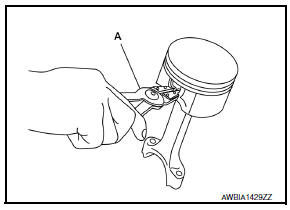

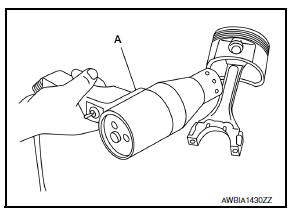

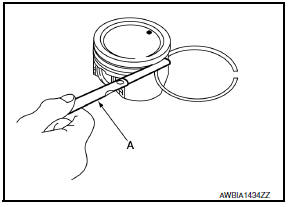

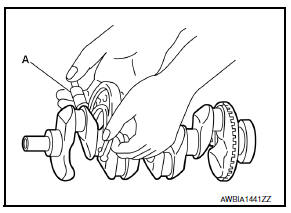

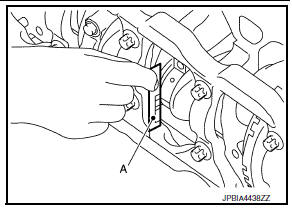

- Remove piston rings using suitable tool (A).

CAUTION:

- When removing piston rings, be careful not to damage the piston.

- Do not damage piston rings by expanding them excessively.

- Remove piston from connecting rod with the following procedure:

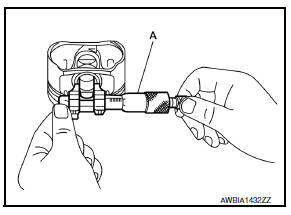

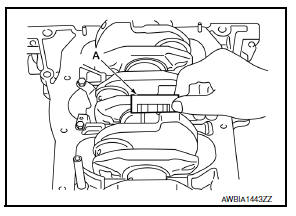

- Using snap ring pliers (A), remove snap rings.

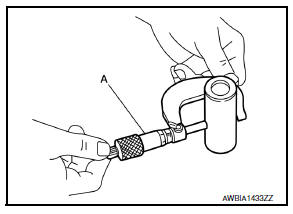

- Heat piston to 60 to 70В°C (140 to 158В°F) with a heat gun (A).

- Push out piston pin using a punch of outer diameter approximately 18 mm (0.71 in).

- Remove main bearing cap bolts.

- Measure crankshaft end play before loosening main bearing cap bolts. Refer to EM-103, "Inspection".

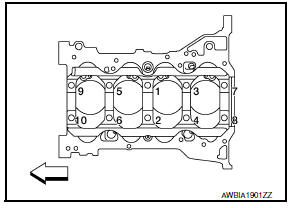

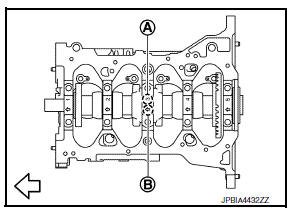

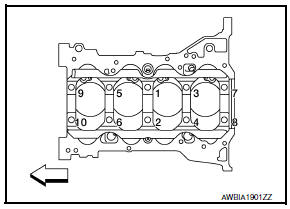

- Loosen and remove main bearing cap bolts in reverse order as shown.

- Remove main bearing caps.

- Tap main bearing caps lightly with a plastic hammer for removal. Number main bearing caps so they can be assembled in the same position and direction.

CAUTION:

Do not damage the mounting surface.

- Remove crankshaft.

CAUTION:

- Do not damage or deform signal plate (1) mounted on rear end of crankshaft (A).

- When setting crankshaft on a flat floor surface, use a block of wood to avoid interference between signal plate and the floor surface.

- Do not remove signal plate unless it is necessary to do so.

- Remove main bearings and thrust bearings from cylinder block and main bearing caps.

CAUTION:

When removing them, note the installation position. Keep them in the correct order.

ASSEMBLY

CAUTION:

Do not reuse washers.

- Fully air-blow engine coolant and engine oil passages in cylinder block, cylinder bore and crankcase to remove any foreign material.

CAUTION:

Use goggles to protect your eyes.

- Install each plug to cylinder block as shown.

(2) : Washer

- Apply liquid gasket to the thread of water drain plug (4).

Use Genuine Silicone RTV Sealant, or equivalent. Refer to GI-21, "Recommended Chemical Products and Sealants".

- Apply sealant to the thread of plug (1).

Use Genuine Silicone RTV Sealant, or equivalent. Refer to GI-21, "Recommended Chemical Products and Sealants".

NOTE:

Do not apply liquid gasket or high strength thread locking sealant to the plug (3).

- Tighten each plug as specified below.

- Install main bearings and thrust bearings with the following procedure:

- Remove dust, dirt, and engine oil on the bearing mating surfaces of cylinder block and main bearing cap.

- Install thrust bearings to both sides of the No. 3 journal housing (B) on cylinder block.

- Install thrust bearings with the oil groove (A) facing crankshaft arm (outside).

- Install the main bearings paying attention to the direction.

- Before installing main bearings, apply new engine oil to the bearing surface (inside). Do not apply new engine oil to the back surface, but thoroughly clean it.

- When installing, align main bearing to the center position of cylinder block and main bearing cap.

- The difference (A) between main bearing (upper) (1) and main bearing (lower) (3) should be 0.85 mm (0.0335 in) or less when installing.

(2) : Cylinder block

(4) : Main bearing cap

- Ensure the oil holes on cylinder block and oil holes (A) on the main bearings (1) are aligned.

- Install signal plate to crankshaft if removed.

- Set the signal plate with the flange facing toward the counter weight side (engine front side) to the crankshaft rear surface.

- Apply new engine oil to threads and seat surfaces of bolts.

- Position crankshaft (2) and signal plate (1) using a dowel pin, and tighten bolts in numerical order as shown.

(A) : Dowel pin hole

NOTE:

Dowel pin of crankshaft and signal plate is provided as a set for each.

- Remove dowel pin.

CAUTION:

Be sure to remove dowel pin.

- Install crankshaft to cylinder block.

- While turning crankshaft by hand, check that it turns smoothly.

- Install main bearing caps with the following procedure:

- Install main bearing caps referring to the journal No. stamp (A) and front mark (B) as shown.

NOTE:

Main bearing cap cannot be replaced as a single part, because it is machined together with cylinder block.

- Tighten main bearing cap bolts in numerical order as shown.

- Apply new engine oil to threads and seat surfaces of bolts.

CAUTION:

Confirm the tightening angle by using Tool (A). Do not judge by visual inspection without the tool.

Step 1 : 34.3 NВ·m (3.5 kg-m, 25 ft-lb)

Step 2 : 60В° clockwise in numerical order

Tool number : KV10112100 (BT-8653-A)

- After installing bolts, check that crankshaft can be rotated smoothly by hand.

- Check crankshaft end play. Refer to EM-103, "Inspection".

- Install piston to connecting rod with the following procedure:

- Using snap ring pliers, install new snap ring to the groove of the piston rear side.

- Insert it fully into groove to install.

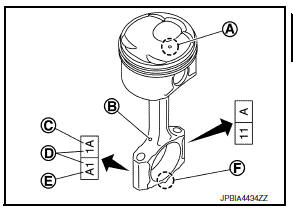

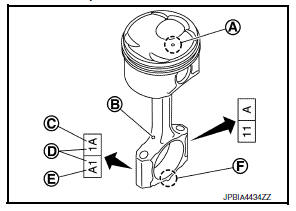

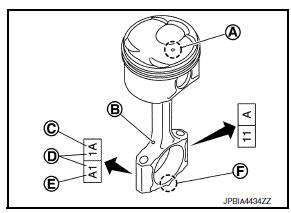

- Assemble piston to connecting rod.

- Using a heat gun, heat the piston until the piston pin can be pushed in by hand without excess force [approximately 60 to 70В°C (140 to 158В°F)]. From the front to the rear, insert piston pin into piston and connecting rod.

- Assemble so that the front mark (A) on the piston head and the oil hole (B) and the cylinder number (D) on connecting rod are positioned as shown.

(C) : Engine type

(E) : Large end hole diameter grade

(F) : Front mark (connecting rod)

- Install new snap ring to the groove of the piston front side.

- Insert it fully into groove to install.

- After installing, check that connecting rod moves smoothly.

CAUTION:

Do not reuse snap rings.

- Using a suitable tool, install piston rings.

CAUTION:

- Do not damage piston.

- Do not damage piston rings by expanding them excessively.

- Position each ring with the gap as shown referring to the piston front mark.

(A) : Oil ring upper or lower rail gap

(B) : Front mark

(C) : Second ring and oil ring spacer gap

(D) : Top ring gap

(E) : Stamped mark

CAUTION:

Do not contact the rail end gap under the oil ring with the oil drain cast groove of piston.

- Install second ring with the stamped surface facing upward.

- Install connecting rod bearing upper (2) and lower (3) to connecting rod (4) and connecting rod cap (4).

(C) : Oil hole (connecting rod)

(D) : View D

(E) : OK

(F) : NG

(g) : 2.55 - 2.95 mm (0.1004 - 0.1161 in)

- Install the connecting rod in the direction shown.

- Check that connecting rod bearing oil hole (A) is completely in the inside of connecting rod oil hole chamfered area (B).

- When installing connecting rod bearings, apply new engine oil to the bearing surface (inside). Do not apply new engine oil to the back surface, but thoroughly clean it.

NOTE:

- There is no positioning tab.

- Install the connecting rod bearings in the center of connecting rod and connecting rod cap as shown. For service operation, the center position can be checked, visually.

- Install piston and connecting rod assembly to crankshaft.

- Position crankshaft pin corresponding to connecting rod to be installed onto the bottom dead center.

- Apply new engine oil sufficiently to the cylinder bore, piston and crankshaft pin.

- Match the cylinder position with the cylinder number (D) on connecting rod to install.

(A) : Front mark (piston)

(B) : Oil hole

(C) : Engine type

(E) : Large end hole diameter grade

(F) : Front mark (connecting rod)

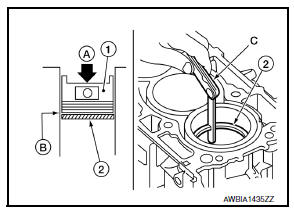

- Install so that front mark (A) on the piston head faces the front of engine.

- Install piston with the front mark on the piston head facing the front of the engine using Tool (A).

CAUTION:

Be careful not to damage the crankshaft pin, resulting from an interference of the connecting rod big end.

Tool number : EM03470000 (J-8037)

- Install connecting rod cap.

- Match the stamped cylinder number marks (D) on connecting rod with those on connecting rod cap to install.

(A) : Front mark (piston)

(B) : Oil hole

(C) : Engine type

(E) : Large end hole diameter grade

(F) : Front mark (connecting rod)

- Tighten connecting rod cap bolt using Tool (A) as follows: Apply new engine oil to the threads and seats of connecting rod cap bolts.

Tool number : KV10112100 (BT-8653-A)

CAUTION:

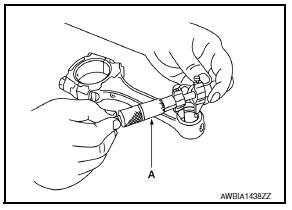

- Check that there is no gap in the thrust surface (A) of the joint between connecting rod (1) and connecting rod cap (2) and that these parts are in the correct position. And then, tighten the connecting rod cap bolts.

- If the connecting rod cap bolts are reused, measure the outer diameter. Refer to EM-103, "Inspection".

Step 1 : 19.6 NВ·m (2.0 kg-m, 14 ft-lb)

Step 2 : 65В° clockwise

CAUTION:

Check and confirm the tightening angle by using Tool. Do not judge by visual inspection without the tool.

Tool number : KV10112100 (BT-8653-A)

- After tightening connecting rod cap bolt, check that crankshaft rotates smoothly.

- Check the connecting rod side clearance. Refer to EM-103, "Inspection".

- Install oil pan (upper). Refer to EM-33, "Exploded View".

- Install rear oil seal. Refer to EM-70, "REAR OIL SEAL : Removal and Installation".

- Install flywheel or drive plate. Refer to EM-90, "Removal and Installation" (M/T) or EM-92, "Removal and Installation" (CVT).

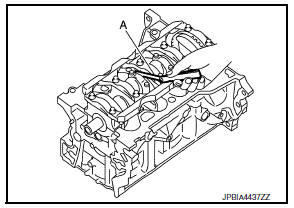

- Install knock sensor.

- Install knock sensor (1) with harness connector facing toward the rear of engine.

(A) : Cylinder block left side

CAUTION:

- Do not tighten bolts while holding the harness connector.

- If any impact by dropping is applied to knock sensor, replace it with a new one.

NOTE:

- Check that there is no foreign material on the cylinder block mating surface and the back surface of knock sensor.

- Check that knock sensor does not interfere with other parts.

- Assembly is in the reverse order of disassembly.

Inspection

CRANKSHAFT END PLAY

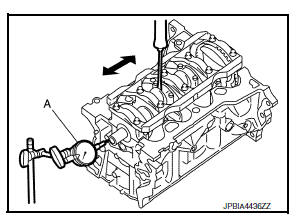

- Measure the clearance between thrust bearings and crankshaft arm when crankshaft is moved fully forward or backward using suitable tool (A).

Standard and Limit : Refer to EM-123, "Cylinder Block".

- If the measured value exceeds the limit, replace thrust bearings, and measure again. If it still exceeds the limit, replace crankshaft also.

Connecting rod side clearance

- Measure the side clearance between connecting rod and crankshaft arm using suitable tool (A).

Standard and Limit : Refer to EM-123, "Cylinder Block".

- If the measured value exceeds the limit, replace connecting rod, and measure again. If it still exceeds the limit, replace crankshaft also.

Piston to piston pin oil clearance

Piston Pin Hole Diameter

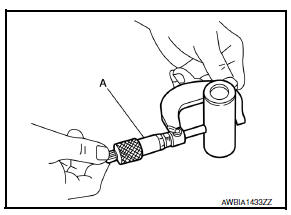

Measure the inner diameter of piston pin hole using suitable tool (A).

Standard : Refer to EM-123, "Cylinder Block".

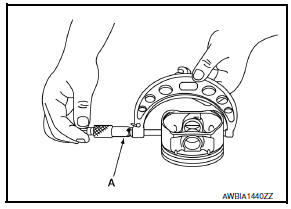

Piston Pin Outer Diameter

Measure the outer diameter of piston pin using suitable tool (A).

Standard : Refer to EM-123, "Cylinder Block".

Piston to Piston Pin Oil Clearance

(Piston to piston pin oil clearance) = (Piston pin hole diameter) – (Piston pin outer diameter)

Standard : Refer to EM-123, "Cylinder Block".

- If oil clearance is out of the standard, replace piston and piston pin assembly.

- When replacing piston and piston pin assembly. Refer to EM-112, "Description".

NOTE:

- Piston is available together with piston pin as assembly.

- Piston pin (piston pin hole) grade is provided only for the parts installed at the plant. For service parts, no grades can be selected. (Only grade “0” is available.)

Piston ring side clearance

- Measure the side clearance of piston ring and piston ring groove using suitable tool (A).

Standard and Limit : Refer to EM-123, "Cylinder Block".

- If the measured value exceeds the limit, replace piston ring, and measure again. If it still exceeds the limit, replace piston also.

Piston ring end Gap

- Check that cylinder bore inner diameter is within specification. Refer to “PISTON TO CYLINDER BORE CLEARANCE”.

- Lubricate with new engine oil to piston (1) and piston ring (2), and then insert (A) piston ring until middle of cylinder (B) with piston, and measure piston ring end gap using suitable tool (C).

Standard and Limit : Refer to EM-123, "Cylinder Block".

- If the measured value exceeds the limit, replace piston ring, and measure again. If it still exceeds the limit, rebore cylinder and use oversized piston and piston rings.

Connecting rod bend and torsion

- Check with a connecting rod aligner.

(A) : Bend

(B) : Torsion

(C) : Feeler gauge

Limit : Refer to EM-123, "Cylinder Block".

- If it exceeds the limit, replace connecting rod assembly.

Connecting rod big end diameter

- Install connecting rod cap (1) without connecting rod bearing installed, and tightening connecting rod cap bolts to the specified torque. Refer to EM-95, "Disassembly and Assembly".

(2) : Connecting rod

(A) : Example

(B) : Measuring direction of inner diameter

- Measure the inner diameter of connecting rod big end using suitable tool.

Standard : Refer to EM-123, "Cylinder Block".

- If out of the standard, replace connecting rod assembly.

Connecting rod bushing oil clearance

Connecting Rod Bushing Inner Diameter

Measure the inner diameter of connecting rod bushing using suitable tool (A).

Standard : Refer to EM-123, "Cylinder Block".

Piston Pin Outer Diameter

Measure the outer diameter of piston pin using suitable tool (A).

Standard : Refer to EM-123, "Cylinder Block".

Connecting Rod Bushing Oil Clearance

(Connecting rod bushing oil clearance) = (Connecting rod bushing inner diameter) – (Piston pin outer diameter)

Standard and Limit : Refer to EM-123, "Cylinder Block".

- If the measured value is out of the standard, replace connecting rod assembly and/or piston and piston pin assembly.

- If replacing piston and piston pin assembly. Refer to EM-112, "Piston".

- If replacing connecting rod assembly. Refer to EM-113, "Connecting Rod Bearing".

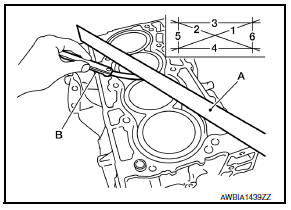

Cylinder block top surface distortion

Using a scraper, remove gasket on the cylinder block surface, and also remove engine oil, scale, carbon, or other contamination.

CAUTION:

Be careful not to allow gasket flakes to enter engine oil or engine coolant passages.

- Measure the distortion on the cylinder block upper face at some different points in six directions using suitable tools (A,B).

Limit : Refer to EM-123, "Cylinder Block".

If it exceeds the limit, replace cylinder block.

Main bearing housing inner diameter

- Install main bearing cap without main bearings installed, and tighten main bearing cap bolts to the specified torque. Refer to EM-95, "Disassembly and Assembly".

- Measure the inner diameter of main bearing housing using suitable tool.

- Measure the position shown [5 mm (0.20 in)] backward from main bearing housing front side in the 2 directions as shown. The smaller one is the measured value.

(1) : Cylinder block

(2) : Main bearing cap

Standard : Refer to EM-123, "Cylinder Block".

- If out of the standard, replace cylinder block and main bearing caps assembly

NOTE:

Main bearing cap cannot be replaced as a single part, because it is machined together with cylinder block

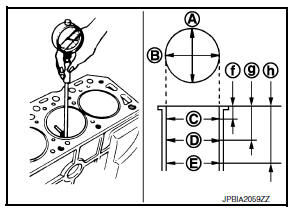

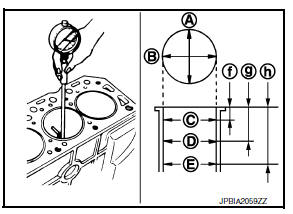

Piston to cylinder bore clearance

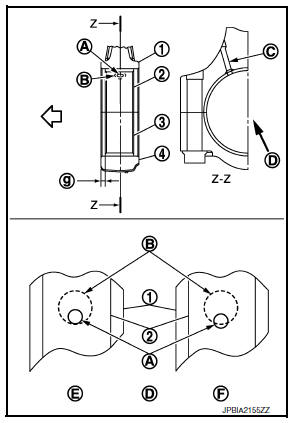

Cylinder Bore Inner Diameter

- Measure the cylinder bore for wear, out-of-round and taper at six different points on each cylinder using suitable tool. [(A) and (B) directions at (C), (D), and (E)] [(A) is in longitudinal direction of engine]

(f) : 10 mm (0.39 in)

(g) : 60 mm (2.36 in)

(h) : 130 mm (5.12 in)

NOTE:

When determining cylinder bore grade, measure the cylinder bore (B) direction at (D) position.

Standard:

Cylinder bore inner diameter : Refer to EM-123, "Cylinder Block".

Limit:

Out-of-round [Difference between (A) and (B)] Taper [Difference between (C) and (D)] : Refer to EM-123, "Cylinder Block".

- If the measured value exceeds the limit, or if there are scratches and/or seizure on the cylinder inner wall, replace cylinder block.

NOTE:

Oversize piston is not provided.

Piston Skirt Diameter

Measure the outer diameter of piston skirt using suitable tool (A).

Standard : Refer to EM-123, "Cylinder Block".

Piston to Cylinder Bore Clearance

Calculate by piston skirt diameter and cylinder bore inner diameter [direction (B), position (D)].

(A) : Direction A

(C) : Position C

(E) : Position E

(f) : 10 mm (0.39 in)

(g) : 60 mm (2.36 in)

(h) : 130 mm (5.12 in)

(Clearance) = (Cylinder bore inner diameter) – (Piston skirt diameter)

Standard and Limit : Refer to EM-123, "Cylinder Block".

- If it exceeds the limit, replace piston and piston pin assembly and/or cylinder block. Refer to EM-112, "Piston".

Crankshaft main journal diameter

- Measure the outer diameter of crankshaft main journals using suitable tool (A).

Standard : Refer to EM-123, "Cylinder Block".

- If out of the standard, measure the main bearing oil clearance.

Then use undersize bearing. Refer to EM-127, "Main Bearing".

Crankshaft pin journal diameter

- Measure the outer diameter of crankshaft pin journal using suitable tool.

Standard : Refer to EM-123, "Cylinder Block".

- If out of the standard, measure the connecting rod bearing oil clearance. Then use undersize bearing. Refer to EM-127, "Connecting Rod Bearing".

Out-of-round and taper of crankshaft

- Measure the dimensions at four different points as shown on each main journal and pin journal using suitable tool.

- Out-of-round is indicated by the difference in dimensions between (X) and (Y) at (A) and (B).

- Taper is indicated by the difference in dimension between (A) and (B) at (X) and (Y).

Limit: Out-of-round [Difference between (X) and (Y)] Taper [Difference between (A) and (B)] : Refer to EM-123, "Cylinder Block".

- If the measured value exceeds the limit, correct or replace crankshaft.

- If corrected, measure the bearing oil clearance of the corrected main journal and/or pin journal. Then select main bearing and/or connecting rod bearing. Refer to EM-113, "Connecting Rod Bearing" and/or EM-115, "Main Bearing".

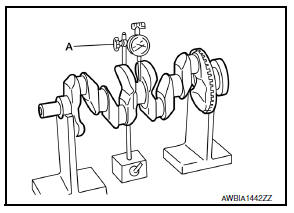

Crankshaft runout

- Place a v-block on a precise flat table to support the journals on both ends of the crankshaft.

- Place a suitable tool (a) straight up on the no. 3 Journal.

- While rotating crankshaft, read the movement of the pointer on the suitable tool (a). (Total indicator reading)

Standard and limit : refer to em-123, "cylinder block".

- If it exceeds the limit, replace crankshaft.

Connecting rod bearing oil clearance

Method by Calculation

- Install connecting rod bearings (2) to connecting rod (3) and connecting rod bearing cap (1), and tighten connecting rod cap bolts to the specified torque. Refer to EM-95, "Disassembly and Assembly".

(A) : Example

(B) : Inner diameter measuring direction

- Measure the inner diameter of connecting rod bearing using suitable

tool.

(Bearing oil clearance) = (Connecting rod bearing inner diameter) – (Crankshaft pin journal diameter)

Standard and Limit : Refer to EM-127, "Connecting Rod Bearing".

- If clearance exceeds the limit, select proper connecting rod bearing according to connecting rod big end diameter and crankshaft pin journal diameter to obtain specified bearing oil clearance. Refer to EM-113, "Connecting Rod Bearing".

Method of Using Plastigage

- Remove engine oil and dust on crankshaft pin and the surfaces of each bearing completely.

- Cut a plastigage slightly shorter than the bearing width, and place it in crankshaft axial direction, avoiding oil holes.

- Install connecting rod bearings to connecting rod and cap, and tighten connecting rod cap bolts to the specified torque. Refer to EM-95, "Disassembly and Assembly".

CAUTION:

Do not rotate crankshaft.

- Remove connecting rod cap and bearing, and using the scale (A) on the plastigage bag, measure the plastigage width.

NOTE:

The procedure when the measured value exceeds the limit is same as that described in the “Method by Calculation”.

Main bearing oil clearance

Method by Calculation

- Install main bearings (3) to cylinder block (1) and main bearing cap

(2), and tighten main bearing cap bolts to the specified torque.

Refer to EM-95, "Disassembly and Assembly".

(A) : Example

(B) : Inner diameter measuring direction

- Measure the inner diameter of main bearing using suitable tool.

(Bearing oil clearance) = (Main bearing inner diameter) – (Crankshaft main journal diameter)

Standard and Limit : Refer to EM-127, "Main Bearing".

- If clearance exceeds the limit, select proper main bearing according to main bearing inner diameter and crankshaft main journal diameter to obtain specified bearing oil clearance. Refer to EM-115, "Main Bearing".

Method of Using Plastigage

- Remove engine oil and dust on crankshaft main journal and the surfaces of each bearing completely.

- Cut a plastigage slightly shorter than the bearing width, and place it in crankshaft axial direction, avoiding oil holes.

- Install main bearings to cylinder block and main bearing cap, and tighten main bearing cap bolts to the specified torque. Refer to EM-95, "Disassembly and Assembly".

CAUTION:

Do not rotate crankshaft.

- Remove main bearing cap and bearings, and using the scale (A) on the plastigage bag, measure the plastigage width.

NOTE:

The procedure when the measured value exceeds the limit is the same as that described in the “Method by Calculation”.

Main bearing crush height

- When main bearing cap is removed after being tightened to the specified torque with main bearings (1) installed, the tip end of bearing must protrude (B). Refer to EM-95, "Disassembly and Assembly".

(A) : Example

Standard : There must be crush height.

- If the standard is not met, replace main bearings.

Connecting rod bearing crush height

- When connecting rod cap is removed after being tightened to the specified torque with connecting rod bearings (1) installed, the tip end of bearing must protrude (B). Refer to EM-95, "Disassembly and Assembly".

(A) : Example

Standard : There must be crush height.

- If the standard is not met, replace connecting rod bearings.

Main bearing cap bolt outer diameter

- Measure the outer diameters (d1) and (d2) at two positions as shown.

(A) : (d1) measuring position

(B) : (d2) measuring position

- If reduction appears in places other than (b) range, regard it as (d2).

Limit [(d1) – (d2)]: 0.15 Mm (0.0059 In)

- If it exceeds the limit (a large difference in dimensions), replace main bearing cap mounting bolt with a new one.

Connecting rod cap bolt outer diameter

- Measure the outer diameter (d) at position as shown.

- If reduction appears in a position other than (d), regard it as (d).

Limit: 7.75 Mm (0.3051 In)

- When (d) exceeds the limit (when it becomes thinner), replace connecting rod cap bolt with a new one.

Drive plate

Drive plate

Exploded View

Pilot converter

Drive plate

Reinforcement plate

Chamfered

Removal and Installation

REMOVAL

Remove the engine and the transaxle assembly from the vehicle, and

...

How to select piston and bearing

How to select piston and bearing

Description

Selection points

Selection parts

Selection items

Selection methods

Between cylinder block and

crankshaft

Main bearing

Main bearing grade (bearing

thi ...

Other materials:

Diagnosis system (EPS control unit)

CONSULT Function

FUNCTION

CONSULT can display each diagnostic item using the diagnostic

test modes shown following.

Diagnostic test mode

Function

ECU identification

The part number stored in the control unit can be read.

Self diagnostic result

Self-diagnostic r ...

Low tire pressure warning lamp does not turn on

Low Tire pessure Warning Lamp Does Not Come On When Ignition Switch Is

Turned On

Note:

The Signal Tech II Tool (J-50190) can be used to perform the following

functions. Refer to the Signal Tech II

User Guide for additional information.

Activate and display TPMS transmitter IDs

Display t ...

Additional service when removing battery negative terminal

Description

When the battery negative terminal is disconnected, the initialization is

necessary for normal operation of

power window system.

CAUTION:

The following specified operations can not be performed under the

non-initialized condition.

Auto-up operation

Anti-pinch function

Wo ...