Nissan Sentra Service Manual: Power supply and ground circuit

Diagnosis Procedure

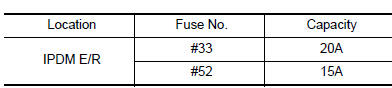

1.CHECK FUSE

Check that the following fuse is not fusing.

Is the fuse fusing? YES >> Replace the fuse after repairing the applicable circuit.

NO >> GO TO 2.

2.CHECK GROUND CONNECTION

- Turn ignition switch OFF

- Check ground connection E9 and E15. Refer to GI-42, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace ground connection.

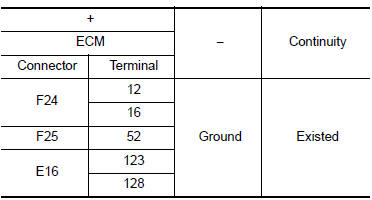

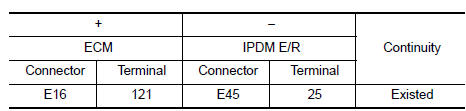

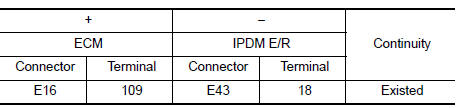

3.CHECK ECM GROUND CIRCUIT

- Disconnect ECM harness connectors.

- Check the continuity between ECM harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

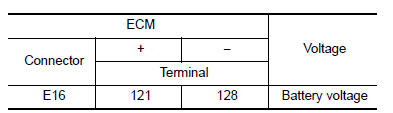

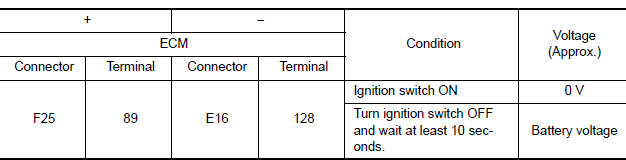

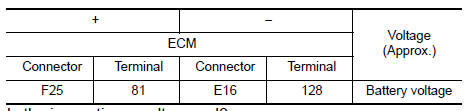

4.CHECK ECM POWER SUPPLY (MAIN)-1

- Reconnect ECM harness connector.

- Turn ignition switch ON.

- Check the voltage between ECM harness connector terminals.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 6.

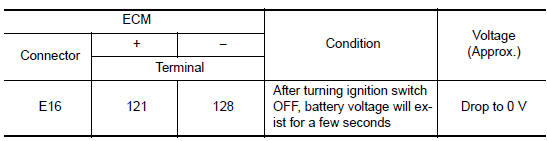

5.CHECK ECM POWER SUPPLY (MAIN)-2

- Turn ignition switch OFF and wait at least 10 seconds.

- Check the voltage between ECM harness connector terminals as per the following.

Is the inspection result normal? YES >> GO TO 9.

NO >> GO TO 7.

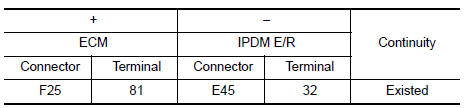

6.CHECK ECM POWER SUPPLY (MAIN) CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connectors.

- Disconnect IPDM E/R harness connector.

- Check the continuity between ECM harness connector and IPDM E/R harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

7.CHECK ECM RELAY CONTROL SIGNAL

Check the voltage between ECM harness connector terminals as per the following.

Is the inspection result normal? YES >> Check Intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> GO TO 8.

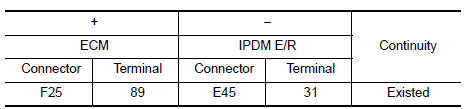

8.CHECK ECM RELAY CONTROL SIGNAL CIRCUIT

- Turn ignition switch OFF

- Disconnect ECM harness connector.

- Disconnect IPDM E/R harness connector

- Check the continuity between ECM harness connector and IPDM E/R harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> Replace IPDM E/R. Refer to PCS-58, "Removal and Installation" (with intelligent key), PCS-58, "Removal and Installation" (without intelligent key).

NO >> Repair or replace error-detected parts.

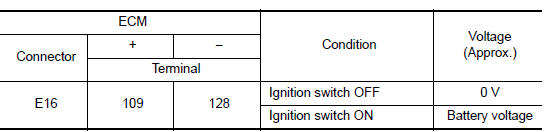

9.CHECK IGNITION SWITCH SIGNAL

- Turn ignition switch ON.

- Check the voltage between ECM harness connector terminals.

Is the inspection result normal? YES >> GO TO 11.

NO >> GO TO 10.

10.CHECK IGNITION SWITCH SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Disconnect IPDM E/R harness connector.

- Check the continuity between ECM harness connector and IPDM E/R harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

11.CHECK ECM POWER SUPPLY (BACK-UP)

Check the voltage between ECM harness connector terminals.

Is the inspection result normal? YES >> Check Intermittent Incident. Refer to GI-39, "Intermittent Incident".

NO >> GO TO 12.

12.CHECK ECM POWER SUPPLY (BACK-UP) CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Disconnect IPDM E/R harness connector.

- Check the continuity between ECM harness connector and IPDM E/R harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

Trouble diagnosis - specification

value

Trouble diagnosis - specification

value

Description

The specification (SP) value indicates the tolerance of the value that is

displayed in “SPEC” of “DATA MONITOR”

mode of CONSULT during normal operation of the Engin ...

U0101 can comm circuit

U0101 can comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellen ...

Other materials:

C1155 BR Fluid level low

DTC Logic

Dtc detection logic

Dtc

Display item

Malfunction detected condition

Possible cause

C1155

C1155 br fluid level low

Brake fluid level is low or communication line between

the abs actuator and electric unit (control unit) and brake

fluid level switch is ...

Precaution for supplemental restraint system (srs) "air bag" and "seat belt

pre-tensioner"

The supplemental restraint system such as “air bag” and “seat belt pre-tensioner”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system ...

P060A ECM

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P060A

CONTROL MODULE

(Internal control module

monitoring processor performance)

ECM internal monitoring processor is malfunctioning. ...