Nissan Sentra Service Manual: Trouble diagnosis - specification value

Description

The specification (SP) value indicates the tolerance of the value that is displayed in “SPEC” of “DATA MONITOR” mode of CONSULT during normal operation of the Engine Control System. When the value in “SPEC” of “DATA MONITOR” mode is within the SP value, the Engine Control System is confirmed OK. When the value in “SPEC” of “DATA MONITOR” mode is NOT within the SP value, the Engine Control System may have one or more malfunctions.

The SP value is used to detect malfunctions that may affect the Engine Control System, but will not light the MIL.

The SP value will be displayed for the following three items:

- B/FUEL SCHDL (The fuel injection pulse width programmed into ECM prior to any learned on board correction)

- A/F ALPHA-B1 (The mean value of air-fuel ratio feedback correction factor per cycle)

- MAS A/F SE-B1 (The signal voltage of the mass air flow sensor)

Component Function Check

1.START

Make sure that all of the following conditions are satisfied.

- Vehicle driven distance: More than 5,000 km (3,107 miles)

- Barometric pressure: 98.3 - 104.3 kPa (1.003 - 1.064 kg/cm2, 14.25 - 15.12 psi)

- Atmospheric temperature: 20 - 30В°C (68 - 86В°F)

- Engine coolant temperature: 75 - 95В°C (167 - 203В°F)

- Transmission: Warmed-up

- CVT models: After the engine is warmed up to normal operating temperature, drive vehicle until “FLUID TEMP SE” (CVT fluid temperature sensor signal) indicates more than 60°C (140°F).

- M/T models: After the engine is warmed up to normal operating temperature, drive vehicle for 5 minutes.

- Electrical load: Not applied

- Rear window defogger switch, air conditioner switch, lighting switch are OFF. Steering wheel is straight ahead.

- Engine speed: Idle

>> GO TO 2.

2.PERFORM “SPEC” OF “DATA MONITOR” MODE

With CONSULT

With CONSULT

NOTE:

Perform “SPEC” in “DATA MONITOR” mode in maximum scale display.

- Perform EC-131, "Work Procedure".

- Select “B/FUEL SCHDL”, “A/F ALPHA-B1” and “MAS A/F SE-B1” in “SPEC” of “DATA MONITOR” mode of “ENGINE” using CONSULT.

- Make sure that monitor items are within the SP value.

Is the inspection result normal?

YES >> END

NO >> Proceed to EC-158, "Diagnosis Procedure".

Diagnosis Procedure

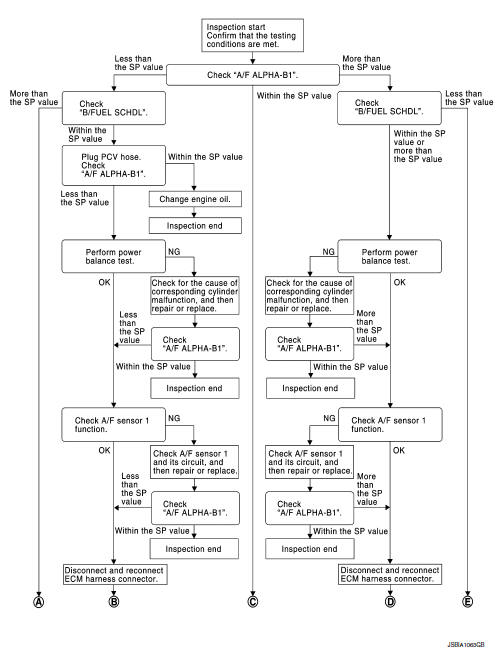

OVERALL SEQUENCE

DETAILED PROCEDURE

1.CHECK “A/F ALPHA-B1”

With CONSULT

With CONSULT

- Start engine.

- Confirm that the testing conditions are met. Refer to EC-157, "Component Function Check".

- Select “A/F ALPHA-B1” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the SP value.

NOTE:

Check “A/F ALPHA-B1” for approximately 1 minute because it may fluctuate. It is NG if the indication is out of the SP value even a little.

Is the measurement value within the SP value? YES >> GO TO 14.

NO-1 >> Less than the SP value: GO TO 2.

NO-2 >> More than the SP value: GO TO 3.

2.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the SP value.

Is the measurement value within the SP value? YES >> GO TO 4.

NO >> More than the SP value: GO TO 16.

3.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the SP value.

Is the measurement value within the SP value? YES >> GO TO 6.

NO-1 >> More than the SP value: GO TO 6.

NO-2 >> Less than the SP value: GO TO 22.

4.CHECK “A/F ALPHA-B1”

- Stop the engine

- Disconnect PCV hose, and then plug it.

- Start engine.

- Select “A/F ALPHA-B1” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the SP value.

Is the measurement value within the SP value? YES >> GO TO 5.

NO >> GO TO 6.

5.CHANGE ENGINE OIL

- Stop the engine.

- Change engine oil.

NOTE:

This symptom may occur when a large amount of gasoline is mixed with engine oil because of driving conditions (such as when engine oil temperature does not rise enough since a journey distance is too short during winter). The symptom will not be detected after changing engine oil or changing driving condition.

>> INSPECTION END

6.PERFORM POWER BALANCE TEST

- Perform “POWER BALANCE” in “ACTIVE TEST” mode

- Make sure that the each cylinder produces a momentary engine speed drop.

Is the inspection result normal? YES >> GO TO 9.

NO >> GO TO 7.

7.DETECT MALFUNCTIONING PART

Check the following.

- Ignition coil and its circuit (Refer to EC-456, "Component Function Check".)

- Fuel injector and its circuit (Refer to EC-450, "Component Function Check".)

- Intake air leakage

- Low compression pressure (Refer to EM-23, "Inspection".)

Is the inspection result normal?

YES >> Replace fuel injector and then GO TO 8.

NO >> Repair or replace malfunctioning part and then GO TO 8.

8.CHECK “A/F ALPHA-B1”

- Start engine.

- Select “A/F ALPHA-B1” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the SP value.

Is the measurement value within the SP value? YES >> INSPECTION END

NO >> GO TO 9.

9.CHECK A/F SENSOR 1 FUNCTION

Perform all DTC CONFIRMATION PROCEDURE related with A/F sensor 1.

- For DTC P0130, refer to EC-210, "DTC Logic".

- For DTC P0131, refer to EC-214, "DTC Logic".

- For DTC P0132, refer to EC-217, "DTC Logic".

- For DTC P014C and P014D, refer to EC-238, "DTC Logic".

- For DTC P2096 and P2097, refer to EC-419, "DTC Logic".

Is any DTC detected? YES >> GO TO 10.

NO >> GO TO 12.

10.CHECK A/F SENSOR 1 CIRCUIT

Perform DIAGNOSTIC PROCEDURE according to corresponding DTC.

>> GO TO 11.

11.CHECK “A/F ALPHA-B1”

- Start engine.

- Select “A/F ALPHA-B1” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the SP value

Is the measurement value within the SP value? YES >> INSPECTION END

NO >> GO TO 12.

12.DISCONNECT AND RECONNECT ECM HARNESS CONNECTOR

- Stop the engine.

- Disconnect ECM harness connector

- Check pin terminal and connector for damage, and then reconnect it.

>> GO TO 13.

13.CHECK “A/F ALPHA-B1”

- Start engine.

- Select “A/F ALPHA-B1” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the SP value.

Is the measurement value within the SP value? YES >> INSPECTION END

NO >> Detect malfunctioning part according to EC-473, "Symptom Table".

14.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the SP value.

Is the measurement value within the SP value? YES >> INSPECTION END

NO-1 >> More than the SP value: GO TO 15.

NO-2 >> Less than the SP value: GO TO 22.

15.DETECT MALFUNCTIONING PART

- Check for the cause of large engine friction. Refer to the following.

- Engine oil level is too high

- Engine oil viscosity

- Belt tension of power steering, alternator, A/C compressor, etc. is excessive

- Noise from engine

- Noise from transmission, etc.

- Check for the cause of insufficient combustion. Refer to the following.

- Valve clearance malfunction

- Intake valve timing control function malfunction

- Camshaft sprocket installation malfunction, etc.

>> Repair or replace malfunctioning part, and then GO TO 27.

16.CHECK INTAKE SYSTEM

Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

- Crushed air ducts

- Malfunctioning seal of air cleaner element

- Uneven dirt of air cleaner element

- Improper specification of intake air system

Is the inspection result normal? YES >> GO TO 21.

NO >> Repair or replace malfunctioning part, and then GO TO 17.

17.CHECK “A/F ALPHA-B1”, AND “B/FUEL SCHDL”

Select “A/F ALPHA-B1” and “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and make sure that each indication is within the SP value.

Is the measurement value within the SP value? YES >> INSPECTION END

NO >> “B/FUEL SCHDL” is more, “A/F ALPHA-B1” is less than the SP value: GO TO 18.

18.DISCONNECT AND RECONNECT MASS AIR FLOW SENSOR HARNESS CONNECTOR

- Stop the engine.

- Disconnect mass air flow sensor harness connector

- Check pin terminal and connector for damage and then reconnect it again.

>> GO TO 19.

19.CHECK “A/F ALPHA-B1”

- Start engine.

- Select “A/F ALPHA-B1” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the SP value.

Is the measurement value within the SP value? YES >> Detect malfunctioning part of mass air flow sensor circuit and repair it. Refer to EC-186, "DTC Logic". Then GO TO 26.

NO >> GO TO 20.

20.CHECK “MAS A/F SE-B1”

Select “MAS A/F SE-B1” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the SP value.

Is the measurement value within the SP value? YES >> GO TO 21.

NO >> More than the SP value: Replace mass air flow sensor, and then GO TO 26.

21.REPLACE ECM

- Replace ECM.

- Perform EC-135, "Work Procedure".

>> GO TO 26.

22.CHECK INTAKE SYSTEM

Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

- Crushed air ducts

- Malfunctioning seal of air cleaner element

- Uneven dirt of air cleaner element

- Improper specification of intake air system

Is the inspection result normal? YES >> GO TO 24.

NO >> Repair or replace malfunctioning part, and then GO TO 23.

23.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the SP value.

Is the measurement value within the SP value? YES >> INSPECTION END

NO >> Less than the SP value: GO TO 24.

24.CHECK “MAS A/F SE-B1”

Select “MAS A/F SE-B1” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the SP value.

Is the measurement value within the SP value? YES >> GO TO 25.

NO >> Less than the SP value: Replace mass air flow sensor, and then GO TO 27.

25.CHECK INTAKE SYSTEM

Check for the cause of air leak after the mass air flow sensor. Refer to the following.

- Disconnection, looseness, and cracks in air duct

- Looseness of oil filler cap

- Disconnection of oil level gauge

- Open stuck, breakage, hose disconnection, or cracks of PCV valve

- Disconnection or cracks of EVAP purge hose, open stuck of EVAP canister purge volume control solenoid valve

- Malfunctioning seal of rocker cover gasket

- Disconnection, looseness, or cracks of hoses, such as vacuum hose, connecting to intake air system parts

- Malfunctioning seal of intake air system, etc.

>> GO TO 27.

26.CHECK “A/F ALPHA-B1” AND “B/FUEL SCHDL

Select “A/F ALPHA-B1” and “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and make sure that each indication is within the SP value.

Is the measurement value within the SP value? YES >> INSPECTION END

NO >> Detect malfunctioning part according to EC-473, "Symptom Table".

27.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and then make sure that the indication is within the SP value.

Is the measurement value within the SP value? YES >> INSPECTION END

NO >> Detect malfunctioning part according to EC-473, "Symptom Table".

Power supply and ground circuit

Power supply and ground circuit

Diagnosis Procedure

1.CHECK FUSE

Check that the following fuse is not fusing.

Is the fuse fusing?

YES >> Replace the fuse after repairing the applicable circuit.

NO >> GO TO 2.

...

Other materials:

Service

Never use electrical test equipment to check SRS circuits unless

instructed to in this Service Manual.

Before servicing the SRS, turn power switch OFF, disconnect battery

negative terminal and wait 3 minutes

or more.

For approximately 3 minutes after the cables are removed, it is stil ...

Uniform tire quality grading

DOT (Department of Transportation) Quality

Grades: All passenger car tires must conform to

federal safety requirements in addition to these

grades.

Quality grades can be found where applicable on

the tire sidewall between tread shoulder and

maximum section width. For example:

Treadwear 200 ...

P1586 G Sensor

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P1586

G Sensor

(Gravity Sensor Circuit)

When the following diagnosis conditions are

satisfied and the detection conditions are satisfi ...