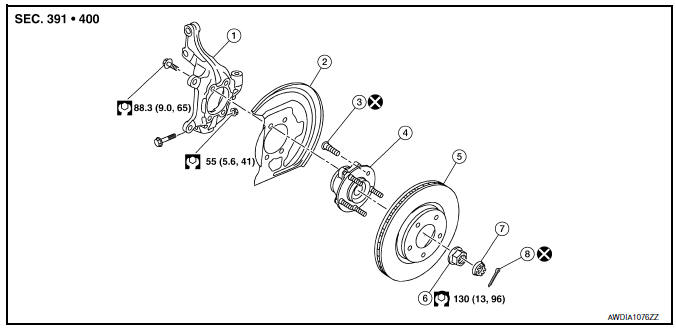

Nissan Sentra Service Manual: Front wheel hub

Exploded View

- Steering knuckle

- Splash guard

- Wheel stud

- Wheel hub and bearing

- Disc brake rotor

- Wheel hub lock nut

- Nut retainer

- Cotter pin

Removal and Installation

- Remove the wheel and tire using power tool. Refer to WT-47, "Exploded View".

- Remove the brake caliper torque member bolts, leaving the brake hose attached. Position the brake caliper aside with wire. Refer to BR-41, "BRAKE CALIPER ASSEMBLY : Removal and Installation".

CAUTION:

Do not depress the brake pedal while the brake caliper is removed.

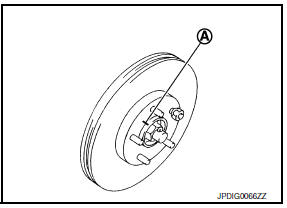

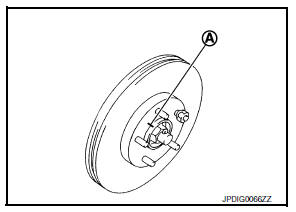

- Put alignment marks (A) on the disc brake rotor and on the wheel hub and bearing. Remove the disc brake rotor.

CAUTION:

Do not drop the disc brake rotor.

CAUTION:

Do not drop the disc brake rotor.

- Remove the wheel sensor bolt. Position the wheel sensor and the wheel sensor harness aside. Refer to BRC-106, "FRONT WHEEL SENSOR : Removal and Installation".

- Remove the cotter pin from the drive shaft.

- Remove the nut retainer from the wheel hub lock nut.

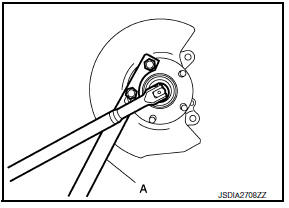

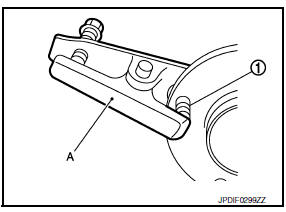

- Hold the wheel hub and bearing using Tool (A). Loosen the wheel hub lock nut.

Tool number (A): KV40104000 ( — )

- Using a piece of wood and a suitable tool, tap on the wheel hub lock nut to disengage the drive shaft from the wheel hub and bearing.

CAUTION:

- Do not place the drive shaft joint at an extreme angle.

Also be careful not to overextend slide joint.

- Do not allow the drive shaft to hang down without support.

NOTE:

Use a suitable puller if the drive shaft cannot be separated from the wheel hub and bearing even after performing the above procedure.

- Remove the wheel hub lock nut.

- Remove the bolts and the wheel hub and bearing from the steering knuckle.

- Remove the splash guard from the steering knuckle.

- Suspend the drive shaft with suitable wire.

- If necessary, remove the wheel studs (1) from the wheel hub and bearing using a suitable tool (A).

CAUTION:

- Remove the wheel studs only when necessary.

- Do not hammer the wheel studs or damage to the wheel hub and bearing may occur.

- Pull out the wheel studs in a direction perpendicular to the wheel hub and bearing.

- Inspect the components. Refer to FAX-10, "Inspection".

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse the wheel stud.

- Do not reuse the cotter pin.

- Place a washer (A) as shown to install the wheel studs (1) by using the tightening force of the nut (B).

CAUTION:

Check that there is no clearance between the wheel stud and the wheel hub and bearing.

- Clean the mating surfaces of the wheel hub lock nut and the wheel hub and bearing.

CAUTION:

- Do not apply lubricating oil to these mating surfaces.

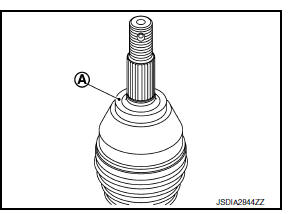

- Clean the mating surfaces of the joint sub-assembly and the wheel hub and bearing. Apply Molykote M77 lubricant to the surface (A) of the joint sub-assembly.

CAUTION:

Apply lubricant to cover the entire flat mating surface of the joint sub-assembly.

NOTE:

Always check with the Parts Department for the latest parts information.

Amount of lubricant : Refer to FAX-49, "Drive Shaft"

- Hold the wheel hub and bearing using Tool. Tighten the wheel hub lock nut.

CAUTION:

- Since the drive shaft is assembled by press-fitting, use a torque wrench to tighten the wheel hub lock nut. Do not use a power tool.

- Too much torque causes axle noise. Too little torque causes wheel bearing looseness. Tighten the wheel hub lock nut to the specification.

Tool number : KV40104000 ( — )

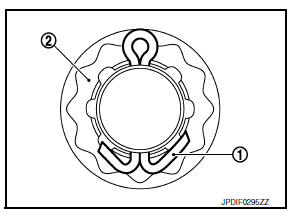

- When installing a the cotter pin (1) and the nut retainer (2), securely bend the cotter pin to prevent rattles.

- Align the matching marks (A) on the disc brake rotor and on the wheel hub and bearing.

- Complete the inspection. Refer to FAX-17, "Inspection".

Inspection

INSPECTION AFTER REMOVAL

Check the following items, and replace the part if necessary.

- Check components for deformation, cracks, and other damage.

- Check boots of transverse link and steering outer socket ball joint for breakage, axial end play, and swing torque.

- Transverse link: Refer to FSU-10, "Inspection".

- Steering outer socket: Refer to ST-8, "Inspection".

INSPECTION AFTER INSTALLATION

- Check the wheel sensor harness to be sure the connectors are fully seated.

- Check the wheel alignment. Refer to FSU-6, "Inspection".

Front drive shaft boot

Front drive shaft boot

Exploded View

(LH)

Circular clip

Dust shield

Slide joint housing

Snap ring

Spider assembly

Boot band

Boot

Shaft

Damper band

Dynamic damper

Circular clip

Joint sub-assembly ...

Other materials:

Multiport Fuel Injection System or Engine Control System

Before connecting or disconnecting any harness connector for the

multiport fuel injection system or ECM:

Turn ignition switch to “OFF” position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

Before disconnecting pressurized fuel line from ...

Dtc/circuit diagnosis

Eco mode switch

Component function check

1. Check eco mode switch operation

Turn ignition switch on.

Check ECO mode indicator lamp turns ON/OFF on combination meter when

turn ECO mode switch ON/

OFF.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Proceed to DM ...

C1115 ABS Sensor [abnormal signal]

DTC Logic

DTC DETECTION LOGIC

DTC

Display Item

Malfunction detected condition

Possible causes

C1115

ABS SENSOR

[ABNORMAL SIGNAL]

When difference in wheel speed between any wheel

and others is detected while the vehicle is driven, because

of installation of t ...