Nissan Sentra Service Manual: Dtc/circuit diagnosis

Eco mode switch

Component function check

1. Check eco mode switch operation

- Turn ignition switch ON.

- Check ECO mode indicator lamp turns ON/OFF on combination meter when turn ECO mode switch ON/ OFF.

Is the inspection result normal? Yes >> inspection end

No >> go to dms-38, "diagnosis procedure".

Diagnosis procedure

Regarding wiring diagram information, refer to dms-28, "wiring diagram".

1.Detect malfunctioning items

What is malfunction items? Eco mode switch illumination does not turns on>>go to 2.

Eco mode indicator lamp does not turns on>>go to 8.

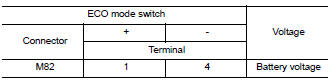

2.Check eco mode switch illumination power supply (1)

- Turn off the headlamp.

- Turn ignition switch OFF

- Disconnect ECO mode switch harness connector

- Turn ignition switch on.

- Turn ON the headlamp

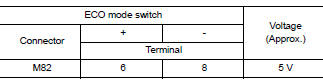

- Check the voltage between eco mode switch harness connector terminals.

Is the inspection result normal? Yes >> go to 3.

No >> go to 4.

3.Check intermittent incidente

Refer to gi-39, "intermittent incident".

Is the inspection result normal? Yes >> replace eco mode switch. Refer to dms-39, "removal and installation".

No >> replace the fuse after repair the applicable circuit.

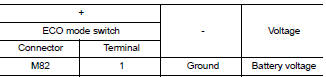

4.Check eco mode switch illumination power supply (2)

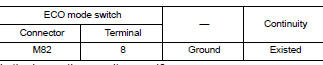

Check the voltage between ECO mode switch harness connector and ground.

Is the inspection result normal? Yes >> go to 7.

No >> go to 5.

5.Check fuse

- Turn off the headlamp.

- Turn ignition switch OFF.

- Pull out #37 fuse. Refer to pg-47, "terminal arrangement".

- Check that the fuse is not fusing.

Is the inspection result normal? Yes >> go to 6.

No >> replace the fuse after repair the applicable circuit.

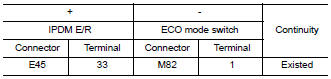

6.Check eco mode switch illumination power supply circuit

- Disconnect IPDM E/R harness connector E45. Refer to INL-26, "Wiring Diagram".

- Check the continuity between ipdm e/r harness connector and eco mode switch harness connector

- Also check harness for short to ground.

Is the inspection result normal? Yes >> perform ipdm e/r auto active test and check tail lamp relay operation. Refer to pcs-9, "diagnosis description" (with intelligent key), pcs-37, "diagnosis description" (without intelligent key).

No >> repair or replace error-detected parts.

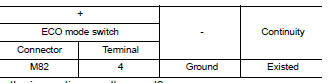

7.Check ground circuit

- Turn off the headlamp.

- Turn ignition switch off.

- Check continuity between eco mode switch harness connector terminal and ground.

Is the inspection result normal? Yes >> check intermittent incident. Refer to gi-39, "intermittent incident".

No >> repair or replace error-detected parts.

8.Check eco mode switch circuit

- Turn ignition switch off

- Disconnect eco mode switch harness connector.

- Turn ignition switch on.

- Check voltage between eco mode switch harness connector terminals

Is the inspection result normal? Yes >> go to 13.

No >> go to 9.

9.Check ground circuit

- Turn ignition switch off.

- Check the continuity between eco mode switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 10.

NO >> Repair or replace damaged parts.

10.Check circuit between combination meter and eco mode switch (1)

- Disconnect combination meter harness connector M24.

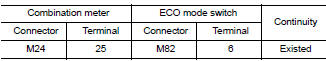

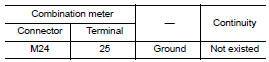

- Check continuity between combination meter harness connector terminal and eco mode switch harness connector terminal

Is the inspection result normal? YES >> GO TO 11.

NO >> Repair or replace damaged parts.

11.Check circuit between combination meter and eco mode switch (2)

Check continuity between combination meter harness connector terminal and ECO mode switch harness connector terminal.

Is the inspection result normal? Yes >> go to 12.

No >> repair or replace damaged parts.

12.Check combination meter input/output signal

- Connect all of disconnected connectors.

- Check input/output signal of combination meter. Refer to MWI-20, "Reference Value".

Is the inspection result normal? Yes >> check intermittent incident. Refer to gi-39, "intermittent incident".

No >> replace combination meter. Refer to mwi-77, "removal and installation".

13.Check eco mode switch

Check eco mode switch. Refer to dms-37, "component inspection".

Is the inspection result normal?

Yes >> check intermittent incident. Refer to gi-39, "intermittent incident".

No >> replace eco mode switch. Refer to dms-39, "removal and installation".

Component inspection

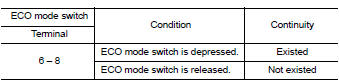

1.Check eco mode switch

Check continuity between eco mode switch connector terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace ECO mode switch. Refer to DMS-39, "Removal and Installation".

Basic inspection

Basic inspection

Diagnosis and repair work flow

Work flow

Detailed flow

1.Obtain information about symptom

Interview the customer to obtain as much information as possible about the

conditions and environment un ...

Symptom diagnosis

Symptom diagnosis

The eco mode indicator lamp does not turn on

Description

The ECO mode indicator lamp does not turn ON when the ECO mode switch is

operated.

Diagnosis Procedure

1.Perform combination meter on boa ...

Other materials:

Can communication circuit

Diagnosis procedure

1.Connector inspection

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Disconnect all the unit connectors on can communication system.

Check terminals and connectors for damage, bend and loose connection.

Is the inspection resu ...

Wiring diagram

Base audio

Wiring diagram

...

Periodic maintenance

Introduction of periodic maintenance

The following tables show the normal maintenance schedule. Depending upon

weather and atmospheric conditions,

varying road surfaces, individual driving habits and vehicle usage, additional

or more frequent maintenance

may be required.

Periodic maintenan ...