Nissan Sentra Service Manual: Can communication circuit

Diagnosis procedure

1.Connector inspection

- Turn the ignition switch OFF.

- Disconnect the battery cable from the negative terminal.

- Disconnect all the unit connectors on can communication system.

- Check terminals and connectors for damage, bend and loose connection.

Is the inspection result normal? Yes >> go to 2.

No >> repair the terminal and connector.

2.Check harness continuity (short circuit)

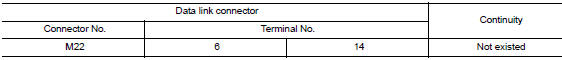

Check the continuity between the data link connector terminals.

Is the inspection result normal? Yes >> go to 3.

No >> check the harness and repair the root cause.

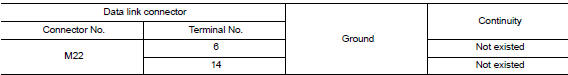

3.Check harness continuity (short circuit)

Check the continuity between the data link connector and the ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Check the harness and repair the root cause.

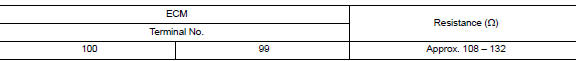

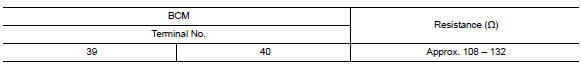

4.Check ecm and bcm termination circuit

- Remove the ecm and the bcm.

- Check the resistance between the ecm terminals.

- Check the resistance between the bcm terminals.

Is the measurement value within the specification? YES >> GO TO 5.

NO >> Replace the ECM and/or the BCM.

5.Check symptom

Connect all the connectors. Check if the symptoms described in the “symptom (results from interview with customer)” are reproduced.

Inspection result

Reproduced>>go to 6.

Non-reproduced>>start the diagnosis again. Follow the trouble diagnosis procedure when past error is detected.

6.Check unit reproduction

Perform the reproduction test as per the following procedure for each unit.

- Turn the ignition switch off.

- Disconnect the battery cable from the negative terminal.

- Disconnect one of the unit connectors of can communication system.

Note:

Ecm and bcm have a termination circuit. Check other units first.

- Connect the battery cable to the negative terminal. Check if the symptoms described in the “symptom (results from interview with customer)” are reproduced.

Note:

Although unit-related error symptoms occur, do not confuse them with other symptoms.

Inspection result

Reproduced>>connect the connector. Check other units as per the above procedure.

Non-reproduced>>replace the unit whose connector was disconnected.

BCM branch line circuit

BCM branch line circuit

Diagnosis procedure

1.Check connector

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the bcm for damage, bend and ...

Can system (type 5)

Can system (type 5)

Dtc/circuit diagnosis ...

Other materials:

Avoiding collision and rollover

WARNINGFailure to operate this vehicle in a safe

and prudent manner may result in loss of

control or an accident.

Be alert and drive defensively at all times. Obey

all traffic regulations. Avoid excessive speed,

high speed cornering, or sudden steering maneuvers,

because these ...

Basic inspection

Diagnosis and repair work flow

Work flow

Overall sequence

Detailed flow

1.Get information for symptom

Get detailed information from the customer about the symptom (the

condition and the environment when

the incident/malfunction occurs).

Check operation condition of the component o ...

Engine compartment

CAUTION

Never use a fuse of a higher or lower

amperage rating than specified on the

fuse box cover. This could damage the

electrical system or cause a fire.

If any electrical equipment does not come on,

check for an open fuse.

Be sure the ignition switch and the headlight

switch are ...