Nissan Sentra Service Manual: P2101 Electric throttle control function

DTC Logic

DTC DETECTION LOGIC

NOTE:

- If DTC P2101 is displayed with DTC P2100, first perform the trouble diagnosis for DTC P2100. Refer to EC-423, "DTC Logic".

- If DTC P2101 is displayed with DTC P2119, first perform the trouble diagnosis for DTC P2119. Refer to EC-430, "DTC Logic".

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition | Possible cause |

| P2101 | ETC FNCTN/CIRC-B1 (Throttle actuator “A” control motor circuit range/performance) | Electric throttle control function does not operate properly. |

|

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11 V when engine is running.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch ON and wait at least 2 seconds.

- Start engine and let it idle for 5 seconds

- Check DTC.

Is DTC detected? YES >> Proceed to EC-425, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

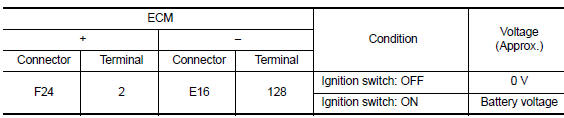

1.CHECK THROTTLE CONTROL MOTOR RELAY INPUT SIGNAL

Check the voltage between ECM harness connector terminals as per the following conditions.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 2.

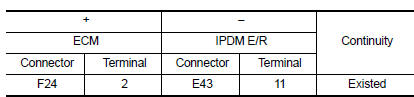

2.CHECK THROTTLE CONTROL MOTOR RELAY INPUT SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Disconnect IPDM E/R harness connector.

- Check the continuity between ECM harness connector and IPDM E/R harness connector

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace error-detected parts.

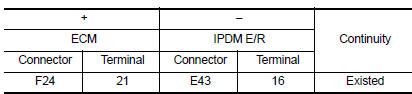

3.CHECK THROTTLE CONTROL MOTOR RELAY POWER SUPPLY CIRCUIT

- Check the continuity between ECM harness connector and IPDM E/R harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

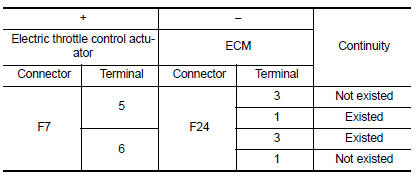

- 4.CHECK THROTTLE CONTROL MOTOR OUTPUT SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect electric throttle control actuator harness connector.

- Disconnect ECM harness connector

- Check the continuity between electric throttle control actuator harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

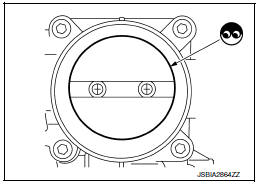

5.CHECK ELECTRIC THROTTLE CONTROL ACTUATOR VISUALLY

- Remove the intake air duct. Refer to EM-25, "Exploded View".

- Check if foreign matter is caught between the throttle valve and the housing.

Is the inspection result normal? YES >> GO TO 6.

NO >> Remove the foreign matter and clean the electric throttle control actuator inside, then perform throttle valve closed position learning. Refer to EC-139, "Work Procedure".

6.CHECK THROTTLE CONTROL MOTOR

Check the throttle control motor. Refer to EC-429, "Component Inspection (Throttle Control Motor)".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Replace electric throttle control actuator. Refer to EM-27, "Removal and Installation".

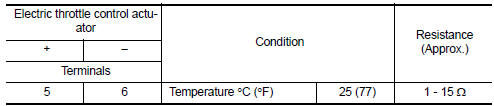

Component Inspection (Throttle Control Motor)

1.CHECK THROTTLE CONTROL MOTOR

- Turn ignition switch OFF.

- Disconnect electric throttle control actuator harness connector.

- Check the resistance between electric throttle control actuator terminals as per the following.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace electric throttle control actuator. Refer to EM-27, "Removal and Installation".

P2100, P2103 Throttle control motorrelay

P2100, P2103 Throttle control motorrelay

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P2100

ETC MOT PWR-B1

(Throttle actuato ...

P2118 Throttle control motor

P2118 Throttle control motor

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P2118

ETC MOT-B1

(Throttle actuator co ...

Other materials:

Symptom diagnosis

OVERHEATING CAUSE ANALYSIS

Troubleshooting Chart

Symptom

Check items

Cooling system

parts

malfunction

Poor heat transfer

Water pump malfunction

Worn or loose drive belt

—

Thermostat stuck closed

Engine coolant circulation

Da ...

P0011 IVT control

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0011 is displayed with DTC P0075, first perform the trouble

diagnosis for EC-180, "DTC Logic".

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0011

INT/V TIM CO ...

Periodic maintenance

Road wheel

Inspection

ALUMINUM WHEEL

Check tires for wear and improper inflation.

Check wheels for deformation, cracks and other damage. If deformed,

remove wheel and check wheel

runout.

Remove tire from aluminum wheel and mount wheel on a balancer machine.

Set dial indicator as ...