Nissan Sentra Service Manual: P0998 Shift solenoid F

DTC Logic

DTC DETECTION LOGIC

| DTC | CONSULT screen terms (Trouble diagnosis content) | DTC detection condition | Possible causes |

| P0998 | SHIFT SOLENOID F (Shift Solenoid F Control Circuit Low) | The TCM low brake solenoid valve current

monitor reading is 200 mA or less continuously

for 480 msec or more under the following diagnosis

conditions: Diagnosis conditions

|

|

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another “DTC CONFIRMATION PROCEDURE” occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

- Start the engine

- Shift the selector lever to “D” position and wait for 5 seconds or more.

- Check the first trip DTC.

Is “P0998” detected? YES >> Go to TM-210, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

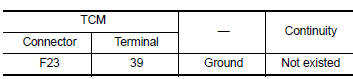

1.CHECK CIRCUIT BETWEEN TCM AND CVT UNIT

- Turn ignition switch OFF.

- Disconnect TCM connector and CVT unit connector.

- Check continuity between TCM harness connector terminal and ground.

Is the inspection

Is the inspection

result normal?

YES >> GO TO 2.

NO >> Repair or replace malfunctioning parts.

2.CHECK LOW BRAKE SOLENOID VALVE

Check low brake solenoid valve. Refer to TM-211, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Repair or replace malfunctioning parts.

Component Inspection

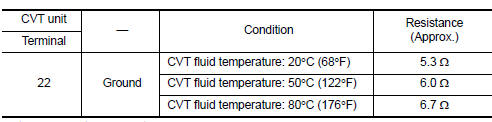

1.CHECK LOW BRAKE SOLENOID VALVE

Check resistance between CVT unit connector terminal and ground.

Is the inspection

Is the inspection

result normal?

YES >> INSPECTION END

NO >> There is a malfunction of low brake solenoid valve. Replace transaxle assembly. Refer to TM-283, "Removal and Installation".

P0967 Pressure control solenoid B

P0967 Pressure control solenoid B

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P0967

PC SOLENOID B

(Pressure Control So ...

P0999 Shift solenoid F

P0999 Shift solenoid F

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P0999

SHIFT SOLENOID F

(Shift Solenoid F ...

Other materials:

Unit disassembly and assembly

Center console assembly

Exploded View

Center console upper finisher

Center console side finisher (RH)

Center console side finisher (LH)

Center console side finisher screw cover

(LH/RH)

Center console assembly

Center console screw cover (LH/RH)

Center console rear finisher

C ...

P0182, P0183 FTT Sensor

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0182

FTT SEN/CIRCUIT

(Fuel temperature sensor

″A″ circuit low)

An excessively low voltage from the sensor is

sent to ...

Wiring diagram

Warning chime system

Wiring diagram

...