Nissan Sentra Service Manual: P0181 FTT Sensor

DTC Logic

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition | Possible cause | |

| P0181 | FTT SENSOR (Fuel temperature sensor ″A″ circuit range/performance) | A) | Rationally incorrect voltage from the sensor is sent to ECM, compared with the voltage signals from ECT sensor and intake air temperature sensor. |

|

| B) | The comparison result of signals transmitted to ECM from each temperature sensor (IAT sensor, ECT sensor, EOT sensor, and FTT sensor) shows that the voltage signal of the FTT sensor is higher/lower than that of other temperature sensors when the engine is started with its cold state. |

|

||

DTC CONFIRMATION PROCEDURE

1.INSPECTION START

Is it necessary to erase permanent DTC? YES >> GO TO 7.

NO >> GO TO 2.

2.PRECONDITIONING

If DTC CONFIRMATION PROCEDURE has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION A-1

- Turn ignition switch ON and wait at least 10 seconds.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-256, "Diagnosis Procedure".

NO >> GO TO 4.

4.CHECK ENGINE COOLANT TEMPERATURE

With CONSULT

With CONSULT

- Select “COOLANT TEMP/S” in “DATA MONITOR” of “ENGINE” using CONSULT.

- Check “COOLANT TEMP/S” value.

With GST

With GST

Follow the procedure “With CONSULT” above.

“COOLANT TEMP/S” less than 60°C (140°F)? YES >> INSPECTION END

NO >> GO TO 5.

5.PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION A-2

With CONSULT

With CONSULT

- Cool engine down until “COOLANT TEMP/S” is less than 60°C (140°F).

- Wait at least 10 seconds.

- Check 1st trip DTC.

With GST

With GST

Follow the procedure “With CONSULT” above.

Is 1st trip DTC detected? YES >> Proceed to EC-256, "Diagnosis Procedure".

NO >> GO TO 6.

6.PERFORM COMPONENT FUNCTION CHECK (FOR MALFUNCTION B)

Perform component function check. Refer to EC-255, "Component Function Check".

NOTE:

Use the component function check to check the overall function of the FTT sensor circuit. During this check, a 1st trip DTC might not be confirmed.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-256, "Diagnosis Procedure".

7.PRECONDITIONING

If DTC CONFIRMATION PROCEDURE has been previously conducted, always perform the following procedure before conducting the next test

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

- Before performing the following procedure, do not add fuel.

- Before performing the following procedure, check that fuel level is between 1/4 and 4/4.

- Before performing the following procedure, confirm that battery voltage is 11 V or more at idle.

>> GO TO 8.

8.PERFORM DTC CONFIRMATION PROCEDURE B

- Move the vehicle to a cool place.

NOTE:

Cool the vehicle in an environment of ambient air temperature between −10В°C (14В°F) and 35В°C (95В°F).

- Turn ignition switch OFF and leave the vehicle for 12 hours.

CAUTION:

Never turn ignition switch ON during this procedure.

NOTE:

The vehicle must be cooled with the food open.

- Start engine and let it idle for 5 minutes or more.

CAUTION:

Never turn ignition switch OFF during idling.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-256, "Diagnosis Procedure".

NO >> INSPECTION END

Component Function Check

1.CHECK FUEL TANK TEMPERATURE (FTT) SENSOR

- Turn ignition switch OFF.

- Disconnect fuel level sensor unit and fuel pump harness connector

- Remove fuel level sensor unit. Refer to FL-6, "Removal and Installation".

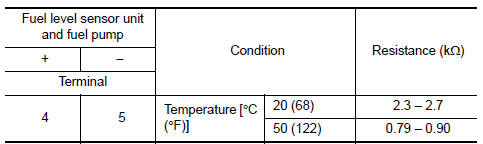

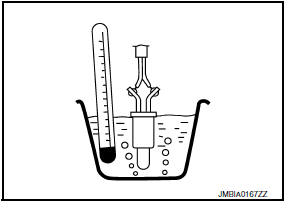

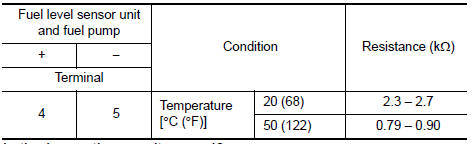

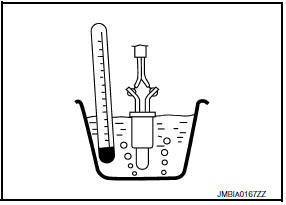

- Check resistance between fuel level sensor unit and fuel pump terminals by heating with hot water as shown in the figure.

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Proceed to EC-256, "Diagnosis Procedure".

Diagnosis Procedure

1.INSPECTION START

Confirm the detected malfunction (A or B). Refer to EC-254, "DTC Logic".

Which malfunction is detected? A >>GO TO 2.

B >>GO TO 6.

2.CHECK DTC WITH COMBINATION METER

Check DTC with combination meter. Refer to MWI-17, "CONSULT Function (METER/M&A)".

Is the inspection result normal? YES >> GO TO 3.

NO >> Proceed to MWI-58, "Diagnosis Procedure".

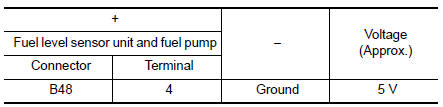

3.CHECK FUEL TANK TEMPERATURE (FTT) SENSOR POWER

- Turn ignition switch OFF.

- Disconnect fuel level sensor unit and fuel pump harness connector.

- Turn ignition switch ON.

- Check the voltage between fuel level sensor unit and fuel pump harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

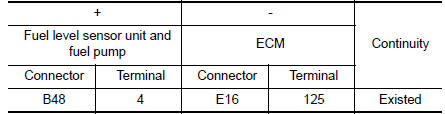

4.CHECK FUEL TANK TEMPERATURE (FTT) SENSOR POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

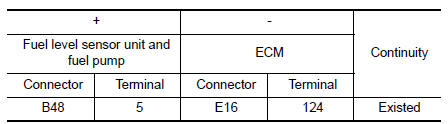

- Check the continuity between fuel level sensor unit and fuel pump harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

5.CHECK FTT SENSOR GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between fuel level sensor unit and fuel pump harness connector and ECM harness connector.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

6.CHECK FUEL TANK TEMPERATURE (FTT) SENSOR

Check the FTT sensor. Refer to EC-257, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Replace fuel level sensor unit and fuel pump. Refer to FL-6, "Removal and Installation".

Component Inspection

1.CHECK FUEL TANK TEMPERATURE (FTT) SENSOR

- Turn ignition switch OFF.

- Disconnect fuel level sensor unit and fuel pump harness connector

- Remove fuel level sensor unit. Refer to FL-6, "Removal and Installation".

- Check resistance between fuel level sensor unit and fuel pump terminals by heating with hot water as shown in the figure.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace fuel level sensor unit and fuel pump. Refer to FL-6, "Removal and Installation".

P0172 Fuel injection system function

P0172 Fuel injection system function

DTC Logic

DTC DETECTION LOGIC

With the Air/Fuel Mixture Ratio Self-Learning Control, the actual mixture

ratio can be brought closely to the

theoretical mixture ratio based on the mixture ratio fe ...

P0182, P0183 FTT Sensor

P0182, P0183 FTT Sensor

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0182

FTT SEN/CIRCUIT

(Fuel temperatur ...

Other materials:

Windshield glass

Exploded View

Windshield glass molding

Spacer

Rubber dam

Windshield glass

Windshield insulator

Front pillar finisher

Instrument panel

Cowl top cover

Roof panel

Cowl top

Body side outer

Headlining

Adhesive

12 +2.0 mm (0.5 +0.08 in)

7 +2.0 mm (0.3 +0.08 in)

...

Rearview mirror (if so equipped)

The night position 1 reduces glare from the

headlights of vehicles behind you at night.

Use the day position 2 when driving in daylight

hours.

WARNINGUse the night position only when

necessary,

because it reduces rear view clarity.

...

P0462, P0463 Fuel level sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0462 or P0463 is displayed with DTC UXXXX, first perform the

trouble diagnosis for DTC

UXXXX.

If DTC P0462 or P0463 is displayed with DTC P0607, first perform the

trouble diagnosis for DTC

P0607. Refer to EC-350, "DTC Logic".

...