Nissan Sentra Service Manual: Intake valve timing control

INTAKE VALVE TIMING CONTROL : System Description

SYSTEM DIAGRAM

INPUT/OUTPUT SIGNAL CHART

| Sensor | Input signal to ECM | ECM function | Actuator | |

| Crankshaft position sensor (POS) | Engine speed and piston position | Intake valve timing control | Intake valve timing control solenoid valve | |

| Camshaft position sensor (PHASE) | ||||

| Engine oil temperature sensor | Engine oil temperature | |||

| Engine coolant temperature sensor | Engine coolant temperature | |||

| Combination meter | CAN communication | Vehicle speed signal | ||

SYSTEM DESCRIPTION

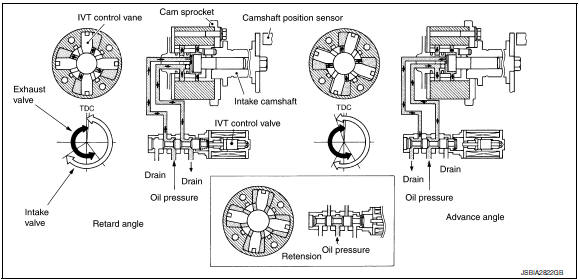

This engine is equipped with an intake valve timing controller (integral with cam sprocket) which continuously adjusts the phase of intake valve according to driving conditions, improves both low/mid range engine torque and high-speed range engine output, and brings about low emission and low fuel consumption.

The intake valve timing control system continuously controls cam phases in constant intake valve operating angle conditions and adjusts an operating oil pressure to the intake valve timing controller via the control solenoid valve.

ECM receives crankshaft position signal, camshaft position signal, engine speed signal, engine oil temperature signal, and engine coolant temperature signal. And the ECM outputs ON/OFF pulse duty signals to the intake valve timing control solenoid valve depending on driving status.

Intake Valve Timing Controller Operation List

| Intake valve timing solenoid valve condition | Intake valve timing controller operation |

| Engine OFF | When starting the engine, the controller vane and sprocket are fixed in full retard position by the reaction force of return spring, improving the starting performance of the engine. |

| Active (Advance angle) | When the energization rate to the control solenoid valve is

increased, the oil pressure from the oil

pump is conveyed to the advance angle chamber of the controller. And

retard angle chamber oil is

drained. Accordingly, the controller vane rotates rightward and the

phase of camshaft becomes advance

angle.

This condition brings about the greater overlap with the exhaust valve, enabling the exhaust gas cleaning by the internal EGR effect and the fuel consumption improvement by the reduction in pumping loss. |

| Neutral (Maintained) | When it is the target valve timing, the energization rate to the control solenoid valve is adjusted to the intermediate state. The solenoid valve is positioned at the neutral position and the oil path is interrupted to maintain the cam shaft phase. |

| Return (Retard angle) | When the energization rate to the control solenoid valve is

decreased, the oil pressure from the oil

pump is conveyed to the retard chamber of the controller. And advanced

angle chamger oil is

drained.

Accordingly, the controller vane rotates leftward and the phase of camshaft becomes retard angle. |

INTAKE VALVE TIMING CONTROL FEEDBACK CONTROL

Cam Position Detection

The camshaft position sensor mounted at the rear of the cylinder head detects a cam position, by using the groove on the plate located at the rear of the intake camshaft.

Feedback Control

The camshaft position sensor feeds back an actual cam position signal to ECM. Based on the signal, ECM controls the intake valve timing control solenoid valve to satisfy the optimum target valve opening/closing timing according to a driving condition.

Electric ignition system

Electric ignition system

ELECTRIC IGNITION SYSTEM : System Description

SYSTEM DIAGRAM

*1: CVT models

*2: M/T models

Input/output signal chart

Sensor

Input Signal to ECM

ECM function

Actuator

...

Exhaust valve timing control

Exhaust valve timing control

EXHAUST VALVE TIMING CONTROL : System

Description

SYSTEM DIAGRAM

INPUT/OUTPUT SIGNAL CHART

Sensor

Input signal to ECM

ECM function

Actuator

Crankshaft position sensor ...

Other materials:

Shift position indicator circuit

Component Parts Function Inspection

1.CHECK SHIFT POSITION INDICATOR

Start the engine.

Shift selector lever.

Check that the selector lever position and the shift position indicator

on the combination meter are identical.

Is the inspection result normal?

YES >> INSPECTION END

N ...

Recommended fluids and lubricants

Fluids and lubricants

*1: For additional information, see “engine oil recommendation”.

*2: As an alternative to this recommended oil, sae 5w-30 conventional

petroleum based oil may be used and meet all specifications

and requirements necessary to maintain the new vehicle limited ...

B0020 Side airbag module LH

Description

DTC B0020 FRONT LH SIDE AIR BAG MODULE

The front LH side air bag module is wired to the air bag diagnosis sensor

unit. The air bag diagnosis sensor

unit will monitor for opens and shorts in detected lines to the front LH side

air bag module.

PART LOCATION

Refer to SRC-5, " ...