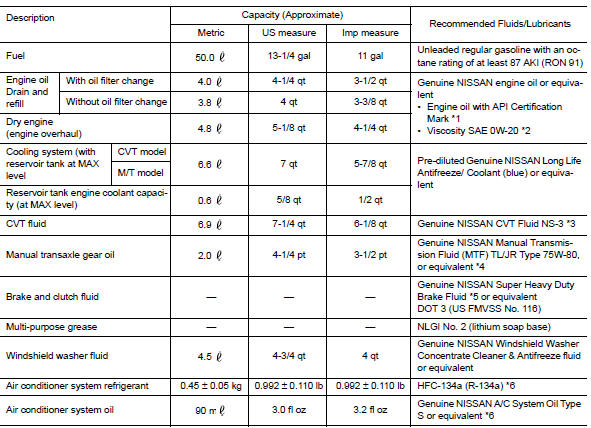

Nissan Sentra Service Manual: Recommended fluids and lubricants

Fluids and lubricants

*1: For additional information, see “engine oil recommendation”.

*2: As an alternative to this recommended oil, sae 5w-30 conventional petroleum based oil may be used and meet all specifications and requirements necessary to maintain the new vehicle limited warranty.

*3: Use only genuine nissan cvt fluid ns-3, using automatic transmission fluid other than genuine nissan cvt fluid ns-3 will damage the cvt, which is not covered by the nissan new vehicle limited warranty.

*4 If genuine nissan manual transmission fluid (mtf) tl/jr type is not available, api gl-4+, viscosity sae 75w-80 may be used as a temporary replacement. However, use genuine nissan manual transmission fluid (mtf) tl/jr type as soon as it is available.

*5: Available in mainland u.S.A. Through a nissan dealer.

*6: For additional information, see "air conditioner specification label".

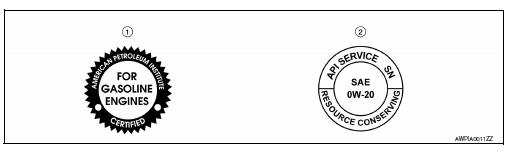

Engine oil recommendation

Nissan recommends the use of an energy conserving oil in order to improve fuel economy. Select only engine oils that meet the american petroleum institute (api) certification and international lubricant standardization and approval committee (ilsac) certification and sae viscosity standard. These oils have the api certification mark on the front of the container. Oils which do not have the specified quality label should not be used as they could cause engine damage.

- Api certification mark

- Api service symbol

Engine coolant mixture ratio

The engine cooling system is filled at the factory with a pre-diluted mixture of 50% genuine nissan long life antifreeze/coolant (blue) and 50% water to provide year-round anti-freeze and coolant protection. The antifreeze solution contains rust and corrosion inhibitors. Additional engine cooling system additives are not necessary.

Warning:

- Do not remove the radiator or coolant reservoir cap when the engine is hot. Wait until the engine and radiator cool down. Serious burns could be caused by high pressure fluid escaping from the radiator.

- The radiator is equipped with a pressure type radiator cap. To prevent engine damage, use only a genuine nissan radiator cap.

Caution:

- When adding or replacing coolant, be sure to use only genuine nissan long life antifreeze/coolant (blue) or equivalent. Genuine nissan long life antifreeze/coolant (blue) is pre-diluted to provide antifreeze protection to -34°f (-37°c). If additional freeze protection is needed due to weather where the vehicle is operated, add genuine nissan long life antifreeze/coolant (blue) concentrate following the directions on the container. If an equivalent coolant other than genuine nissan long life antifreeze/coolant (blue) is used, follow the coolant manufacturer’s instructions to maintain minimum antifreeze protection to -34°f (-37°c). The use of other types of coolant solutions other than genuine nissan long life antifreeze/coolant (blue) or equivalent may damage the engine cooling system.

- Mixing any other type of coolant other than genuine nissan long life antifreeze/coolant (blue), including genuine nissan long life antifreeze/coolant (green), or the use of non-distilled water will reduce the life expectancy of the factory-fill coolant.

Periodic maintenance

Periodic maintenance

Introduction of periodic maintenance

The following tables show the normal maintenance schedule. Depending upon

weather and atmospheric conditions,

varying road surfaces, individual driving habits ...

Engine maintenance

Engine maintenance

Drive belt

Drive belt : inspection

Alternator

Drive belt auto-tensioner

Crankshaft pulley

A/c compressor

Water pump

Drive belt

Possible use range

New drive belt range

Ndica ...

Other materials:

Brake warning lamp

Component Function Check

1.CHECK BRAKE WARNING LAMP FUNCTION (1)

Check that brake warning lamp in combination meter turns ON for

approximately 2 seconds after ignition

switch is turned ON.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Proceed to diagnosis procedure. ...

Unit disassembly and assembly

Front coil spring and strut

Exploded View

Piston rod lock nut

Strut mount insulator

Strut mount bearing

Bound bumper

Coil spring

Lower rubber seat

Strut

Steering knuckle

Front

Disassembly and Assembly

DISASSEMBLY

CAUTION:

Do not damage the piston rod when removing comp ...

Service data and specifications (SDS)

General Specifications

Clutch Pedal

Clutch Disc

Clutch Cover

...