Nissan Sentra Service Manual: Electric ignition system

ELECTRIC IGNITION SYSTEM : System Description

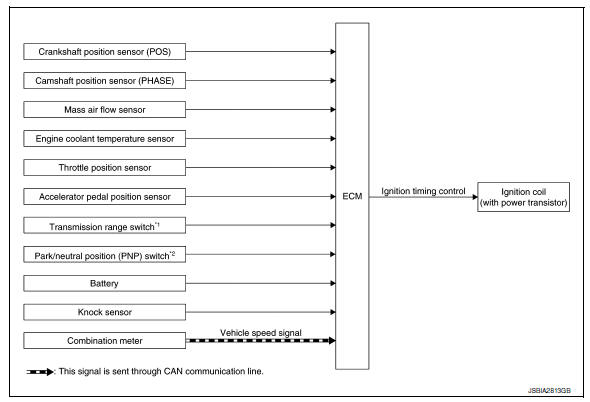

SYSTEM DIAGRAM

*1: CVT models

*2: M/T models

Input/output signal chart

| Sensor | Input Signal to ECM | ECM function | Actuator | |

| Crankshaft position sensor (POS) |

|

Ignition timing control | Ignition coil (with power transistor) | |

| Camshaft position sensor (PHASE) | ||||

| Mass air flow sensor | Amount of intake air | |||

| Engine coolant temperature sensor | Engine coolant temperature | |||

| Throttle position sensor | Throttle position | |||

| Accelerator pedal position sensor | Accelerator pedal position | |||

| Transmission range switch*1 | Gear position | |||

| Park/neutral position (PNP) switch*2 | ||||

| Battery | Battery voltage*3 | |||

| Knock sensor | Engine knocking condition | |||

| Combination meter | CAN communication | Vehicle speed signal | ||

*1: CVT models

*2: M/T models

*3: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

Firing order: 1 - 3 - 4 - 2

The ignition timing is controlled by the ECM to maintain the best air-fuel ratio for every running condition of the engine. The ignition timing data is stored in the ECM.

The ECM receives information such as the injection pulse width and camshaft position sensor (PHASE) signal.

Computing this information, ignition signals are transmitted to the power transistor.

During the following conditions, the ignition timing is revised by the ECM according to the other data stored in the ECM.

- At starting

- During warm-up

- At idle

- At low battery voltage

- During acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not operate under normal driving conditions. If engine knocking occurs, the knock sensor monitors the condition.

The signal is transmitted to the ECM. The ECM retards the ignition timing to eliminate the knocking condition.

Multiport fuel injection system

Multiport fuel injection system

MULTIPORT FUEL INJECTION SYSTEM : System

Description

SYSTEM DIAGRAM

*1: ECM determines the start signal status by the signals of engine speed and

battery voltage.

*2: M/T models

*3: CVT mod ...

Intake valve timing control

Intake valve timing control

INTAKE VALVE TIMING CONTROL : System Description

SYSTEM DIAGRAM

INPUT/OUTPUT SIGNAL CHART

Sensor

Input signal to ECM

ECM function

Actuator

Crankshaft position sensor (P ...

Other materials:

Manual transmission (if so equipped)

WARNING

Do not downshift abruptly on slippery

roads. This may cause a loss of control.

Do not over-rev the engine when shifting

to a lower gear. This may cause a

loss of control or engine damage.

Do not shift to the N (Neutral) position

while driving. Doing so may ...

B0021 Side curtain air bag module LH

Description

DTC B0021 LH SIDE CURTAIN AIR BAG MODULE

The LH side curtain air bag module is wired to the air bag diagnosis sensor

unit. The air bag diagnosis sensor

unit will monitor for opens and shorts in detected lines to the LH side curtain

air bag module.

PART LOCATION

Refer to SRC-5, ...

Abs branch line circuit

Diagnosis procedure

1.Check connector

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the abs actuator and electric unit

(control unit) for damage, bend

and loose connection (unit side and connector side).

...